[Even food like that? ! 】Evolving food freezing methods

Various freezing methods have been developed in the food industry. Frozen foods are used to develop more convenient products and are used in a variety of ways.

We will introduce freeze-drying and freeze-infiltration methods, which are currently attracting attention, as well as the rapid freezing technology that influences the quality of these freezing methods.

目次

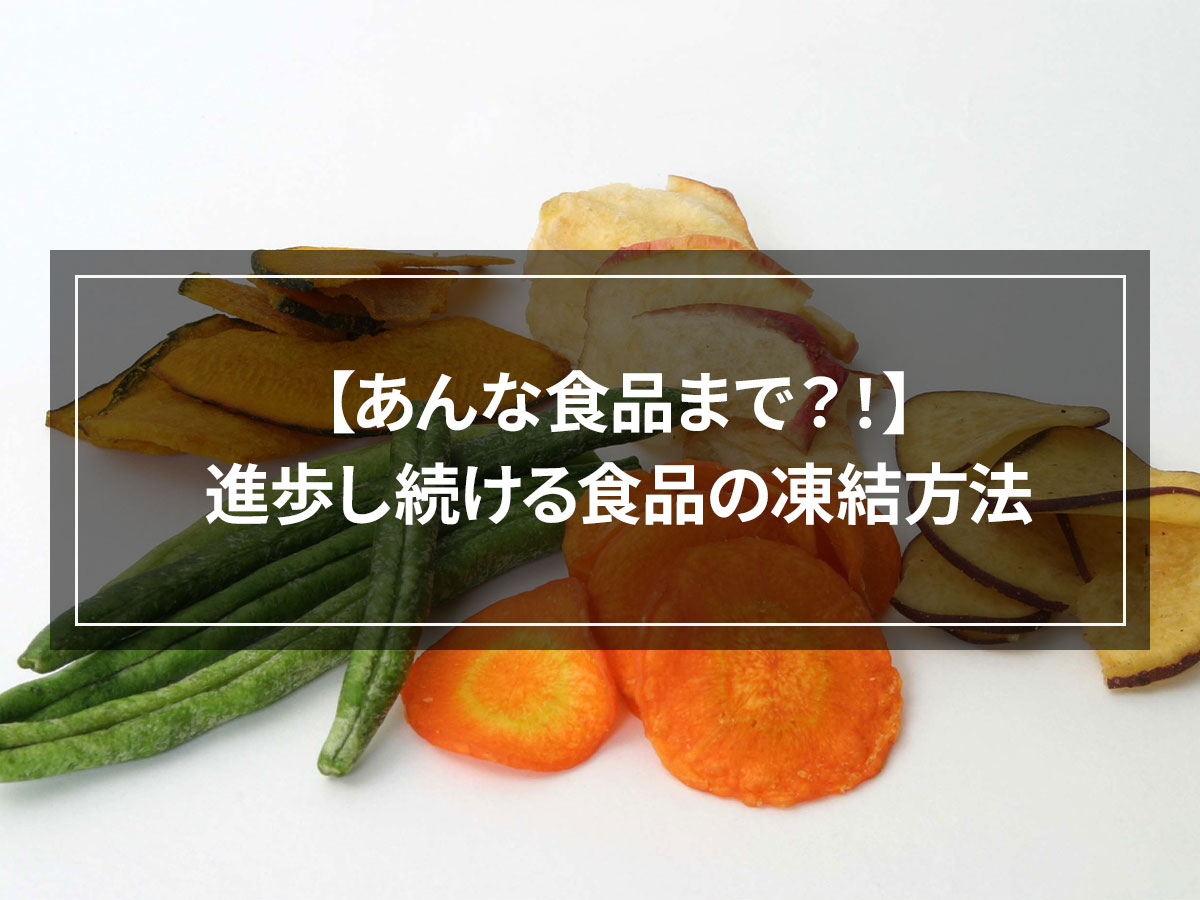

Freeze-drying method restores the original state just by pouring hot water

Freeze-drying is a method of drying frozen foods by sublimation in a vacuum state.

It is also called freeze drying.

Source: http://www.dotwan.jp/fs/dotwan/c/fd

Normal drying involves evaporation from a liquid to a gas, but freeze-drying uses a phenomenon called sublimation, which changes a solid to a gas.

By placing frozen food in a vacuum state and lowering the atmospheric pressure, water can sublimate.

The principle behind this is that when food is frozen, the water in it turns into ice. When ice sublimates, a cavity is created in the space that was originally ice, and the inside of the food becomes empty.

When moisture enters the empty space, it can be easily restored to its original state.

Since the food is dried in a frozen state, there is almost no change in the ingredients of the food, and the color, taste, flavor, and nutritional value can be maintained. Just by adding water or hot water, it immediately returns to its original food state, making it easy to eat.

It was originally developed in the field of emergency medicine to transport blood for transfusions to remote locations. It spread to the Japanese food industry around 1970 with the sale of instant coffee and instant noodles.

Freeze-dried foods have a low moisture content, which suppresses the activity of enzymes and microorganisms, preventing spoilage and deterioration.

Therefore, food can be preserved for a long time without using additives such as preservatives.

Currently, a variety of products are being developed, including miso soup, curry, soup, porridge, rice bowls such as oyakodon and Chinese bowl, and side dishes. It is also used in the field of space food.

"Freeze impregnation method" to soften food

The freeze impregnation method is a method of freezing raw or cooked vegetables, immersing them in an enzyme solution, and then applying vacuum at the same time as thawing to rapidly infiltrate the enzymes into the cells within the food.

When food is frozen, the water in the food freezes, forming ice crystals that cause the tissue to expand, and when the food is thawed, the tissue in the food returns to its original size.

When frozen food is immersed in an enzyme solution and thawed under reduced pressure, the tissue inside the food expands and the enzyme solution penetrates into the food, replacing air within the tissue.

If you remove it from the enzyme solution and heat it, the enzyme action disappears, allowing you to make soft foods while retaining the original flavor and appearance of the food.

The cryo-impregnation method is used for hospital food and nursing care food because it can be made soft enough to be crushed with the gums.

Current general nursing care food consists of food that is mashed in a blender or boiled like porridge, then made into a jelly using a gelling agent. There is no problem at all in terms of nutrition, but there is room for improvement in terms of enjoying the meal.

When frozen and impregnated vegetables are used, they look just like regular vegetables, but they can be crushed with the tongue or gums, making them safe to eat even for elderly people who have difficulty chewing.

For example, vegetables such as bamboo shoots and carrots have a bavarois-like texture and can be easily mashed.

Source: https://www.roken-akashiya.org/about/point/ganshinshoku/

Since it does not soften by heating, the heating time can be shortened, which has the advantage that flavor and nutrients are less likely to be lost.

By enzymatically decomposing the ingredients contained in the food itself, amino acids and functional ingredients can be created, and nutrients such as vitamins are not lost during the processing process.

By adjusting the enzyme concentration and time, even hard vegetables such as root vegetables can be softened. For vegetables, pectinase is used as the enzyme solution, but by changing the enzyme used, it can be used for mushrooms, meat, and fish.

It has also been successfully used to soften fruits such as apples and bananas.

The cryo-impregnation method itself is low cost and can be processed and cooked at hospitals and other facilities, so it is being widely adopted.

In addition, it can be applied to the development of general foods and functional foods, and is expected to be used.

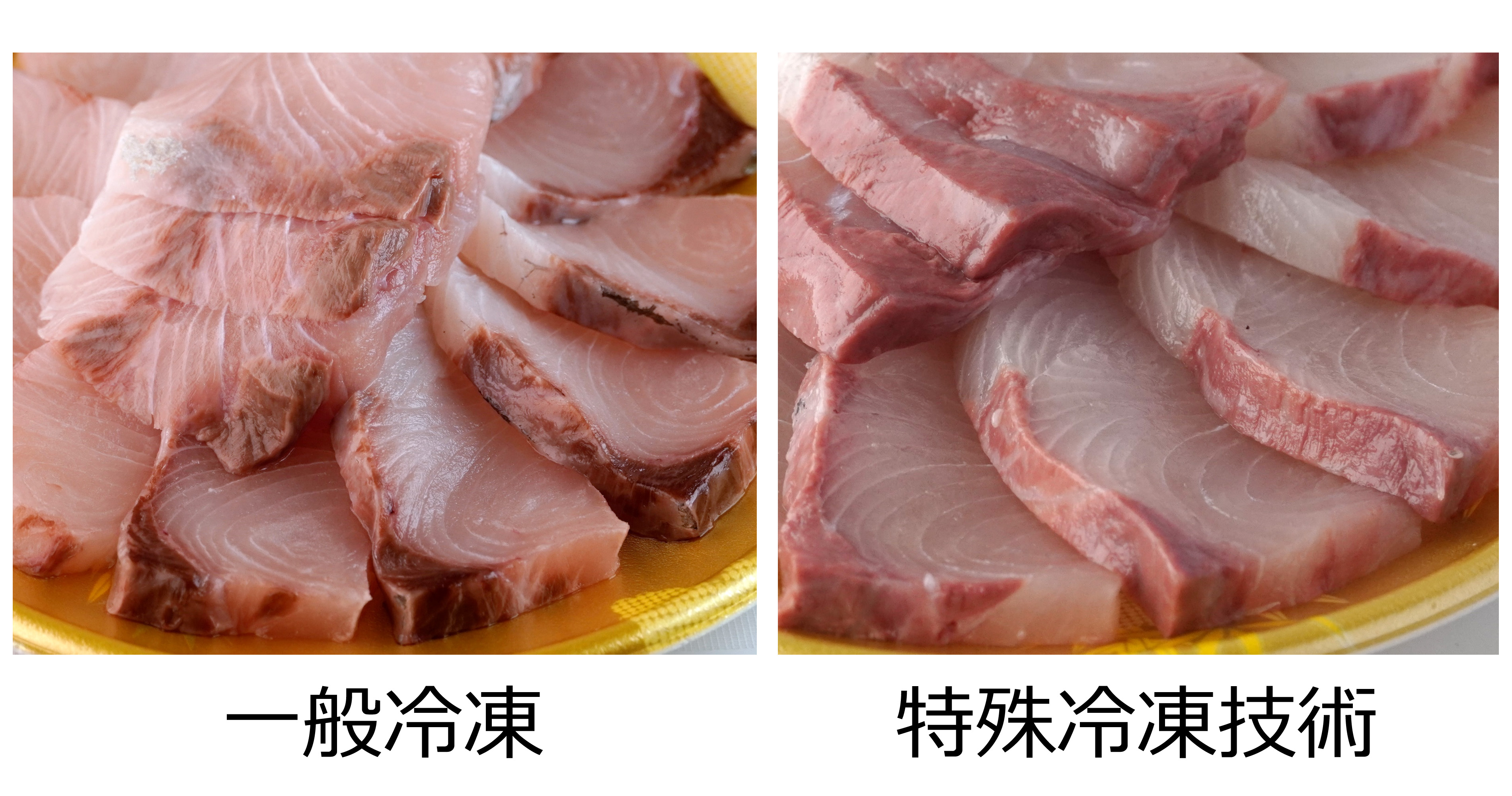

"Quick freezing technology" is essential for freezing food

Both the freeze-drying method and the freeze-impregnation method use frozen foods, so the quality of the food changes depending on the freezing condition. Food that has been frozen in good condition will give you a higher quality product.

Rapid freezing technology enables high-quality freezing.

Originally, the purpose of freezing food was to suppress the activity of enzymes and microorganisms and preserve it for a long period of time. Freezing food can maintain its edible quality, but the disadvantage is that freezing food loses its taste and flavor.

Quick freezing overcomes the disadvantages of freezing and allows food to retain the same deliciousness as before freezing.

Rapid freezing is a freezing method that focuses on quickly passing food through the temperature range of -1℃ to -5℃, where the water in the food freezes.

The reason why food quality deteriorates when it is frozen is that when the water, which makes up most of the food, freezes, it forms into ice crystals that destroy the food's cells, causing drips to flow out along with flavor components and nutrients.

Small ice crystals do not destroy cells, so they can be frozen without compromising quality. Rapid freezing suppresses the growth of ice crystals and prevents cell destruction, thereby preserving food quality.

There are various methods of quick freezing.

Air blast freezing involves freezing food by applying cold air at -40℃ to -50℃.

Magnetic field/electromagnetic wave freezing combines air blast freezing with magnetic field action.

Liquid freezing involves soaking and freezing in a brine solution such as salt water, potassium chloride solution, or alcohol solution.

There are methods to freeze food by spraying it with liquefied nitrogen at -196℃.

There are different freezing methods that are suitable depending on the purpose and the food you want to freeze, but rapid freezing greatly improves the quality of the food.

It can be used with a wide range of foods, from fresh to cooked foods, and reproduces the freshness and taste of freshly made food.

For example, even when freezing fresh fish, we minimize drips when thawing it, keeping it fresh enough to be eaten as sashimi. Additionally, it is now possible to freeze foods that were previously thought to be unsuitable for freezing.

Quick freezing machines have been introduced in various places such as food processing plants, restaurants, and supermarkets, and many foods are quickly frozen and distributed.

It has been shown to be highly effective in the production of frozen foods, but progress is also being made in the development of products that use rapidly frozen foods to freeze-dry or freeze-impregnate them.

Conclusion

Techniques that utilize frozen foods, such as freeze-drying and freeze-infiltration methods, are being developed rapidly.

However, these techniques can only be achieved through high-quality freezing.

Rapid freezing allows more food to be used in a better quality state.

Rapid freezing can be said to be an important technology because it supports the ever-evolving food freezing methods.

⇒⇒Download detailed information on freezing methods

⇒⇒Inquire about quick freezing

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Guide to handling frozen chicken for commercial use] How to thaw and how long it can be used after that](https://shunkashutou.com/wp-content/uploads/2018/04/IMG_15001.jpg)

![[Current situation and countermeasures for food loss] What are efforts to reduce food waste and rapid freezing? ?](https://shunkashutou.com/wp-content/uploads/2024/04/ddc2c5b7fa32b837dcbdcd1ab68e9087.jpg)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2016/03/99093c5fe8b0d716c39df907616e4a96.jpg)

![[Improve your freezer] Tips on temperature control and freezing methods](https://shunkashutou.com/wp-content/uploads/2015/06/freezertemp.jpg)

![[Successful example of rapid freezing] Efforts of Yuko Fisheries Cooperative and regional revitalization by women](https://shunkashutou.com/wp-content/uploads/2015/11/68950ce21415f187d34a8a1d5b48956a.jpg)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2016/06/09c17e4deeb1ac0cdc5a513eaf89ab1a.jpg)