Protect food safety! ! What is food traceability?

Have you ever heard of the word traceability? I think there are many people who have heard the word once, but don't know exactly what it means.

The food industry requires traceability to maintain food safety and consumer trust. In recent years, food-related incidents and accidents such as falsification of production areas and food poisoning have occurred, and consumers have become more sensitive to food-related information.

If you do not know about traceability, you may not be able to continue your business in the unlikely event that an incident or accident occurs.

Therefore, this time we will introduce in detail about food traceability.

This is must-see information for anyone involved in food processing factories or food wholesalers, so please read until the end.

目次

What is food traceability?

Traceability is a combination of two words: "trace" and "ability." When it comes to food products, we create and maintain records regarding the arrival and departure of food at each stage of production, processing, and distribution so that we can trace the route of food movement, such as where food is produced and where it is sold.

Simply put, food traceability means understanding the distribution route of food. So, in what situations is traceability necessary?

Why we need traceability

When is food traceability necessary? This occurs when an incident or accident that affects health occurs, such as food poisoning or foreign substance contamination.

If traceability is implemented in the event of a food accident, it will be possible to find out where the food in question came from and where it has been sold, making it possible to quickly recall the product and investigate the cause of the accident. It can be done.

How traceability became popular

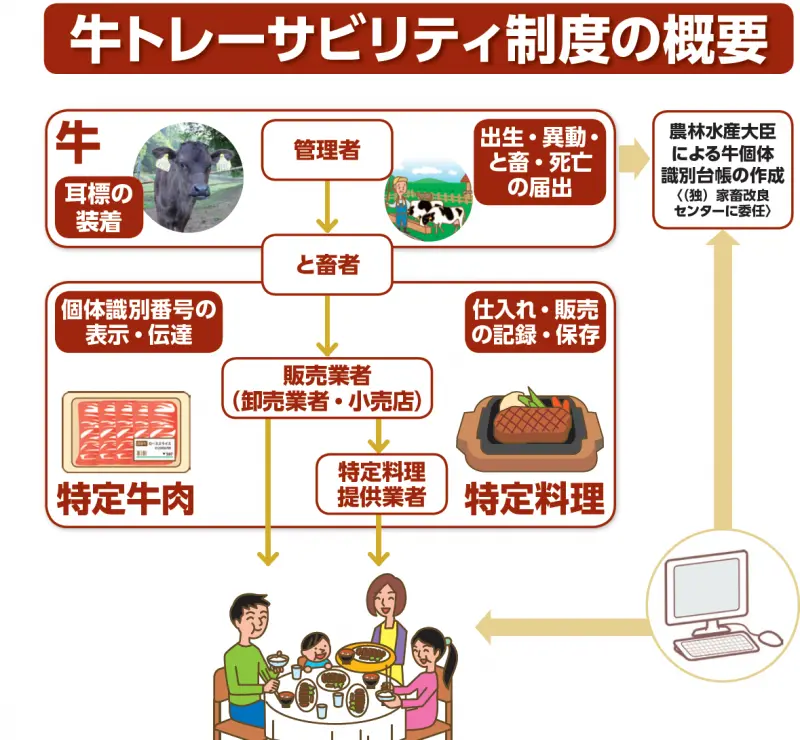

Traceability in food became popular after a major food-related incident. The incident that triggered the outbreak was an outbreak of cattle infected with BSE (bovine spongiform encephalopathy) in Japan in 2001. It was necessary to quickly identify the destination of the cows that were eating the same feed as the BSE-infected cows, and the fact that the incident was widely covered in the news raised concerns among consumers, necessitating measures to recall the beef.

After this incident, a law called the Cattle Traceability Law ("Special Measures Law Concerning the Management and Communication of Information for Individual Identification of Cattle") was enacted in 2004. We have decided to manage the series of products lined up at retail stores using a 10-digit individual identification number and record transaction data.

In addition to beef, ``rice'' also requires traceability by law. The trigger for this was the illicit rice distribution incident that occurred in 2008. Cases in which it was discovered that the accidental rice, which was found to have mold and residual pesticides exceeding standard values and was no longer edible, was also used in processed rice products such as rice crackers, but it was not possible to trace which products the accidental rice was used in. had.

After this incident, the Rice Traceability Act was enacted in 2010 with the aim of identifying rice distribution routes and clarifying information on rice production areas.

As mentioned above, traceability is required for "cow/beef" and "rice/rice processed products" as there have been serious incidents related to food safety in the past.

Why traceability is necessary even for non-mandatory foods

Currently, in Japan, traceability is not required for foods other than "cow/beef" and "rice/rice processed products." However, even for foods for which traceability is not required, it is important to record and store where the food comes from, what process it has gone through, and where it has been shipped.

In the unlikely event that a company that handles food experiences an incident or accident that requires the recall of food, it is necessary to quickly recall the problematic product. At that time, if we can identify the problematic product lot or supplier, we can narrow down the items to be recalled and make it easier to investigate the cause.

Once the cause of the problem is identified, food distribution can quickly return to normal and damage can be limited. In addition, if the distribution process is clear, it is possible to take quick action, so even if a problem occurs, it is possible to recall the product before it reaches the consumer.

On the other hand, if traceability is insufficient, even if there is a product that must be recalled, it is not clear where the product was shipped. If this happens, all products that may cause even the slightest harm will have to be recalled, resulting in greater damage from the recall.

Furthermore, if the cause of an accident is not clear for a long time, there is a risk that the company will lose the trust of business partners, suspend business transactions, and even be forced into bankruptcy.

Depending on how you respond when a serious incident occurs, you may be able to quickly resume your business, or you may lose trust and go bankrupt.

Traceability plays an important role in manufacturing and selling food products.

How to approach it at the factory

I hope you understand that traceability is necessary to protect the trust of business partners and consumers. So what specific measures should we take?

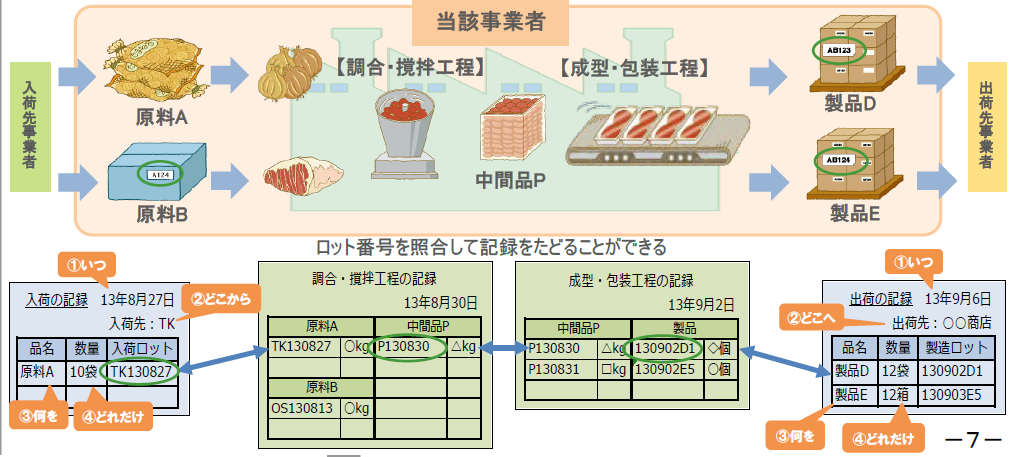

In order to understand how food is being moved, it is necessary to create and store ``receipt records'' and ``shipment records.'' In addition, for large processing plants and companies that manufacture multiple products, having "manufacturing records" allows for a more detailed understanding of the food flow, making it easier to identify problematic products.

Record of arrival

Records the vendor and when the food was received.

There are four required records.

(1) When (arrival date)

(2) From where (delivery destination)

(3) What (product name)

(4) How much (quantity)

Also, some foods have information written on the outer box, so you should store it in a way that makes it easy to identify it.

Shipping records

Record where and when manufactured food was shipped.

There are four required items, similar to the record of arrival.

(1) When (arrival date)

(2) Where (shipping destination)

(3) What (product name)

(4) How much (quantity)

Records at the time of manufacturing

When manufacturing products using multiple foods, knowing which raw materials were used in which products allows for retrospective investigation in case there is a problem with the raw materials or the finished product needs to be recalled. Masu.

By assigning lot numbers based on product type, manufacturing date, manufacturing time, etc., and recording not only finished products but also intermediately prepared products, you will be able to track products more accurately.

Additionally, records must be kept in an organized manner so that they can be checked quickly when needed. The recording medium can be either paper or electronic data, but it is necessary to save the data by date, arrival destination, and shipping destination so that it can be checked immediately.

Specifically, methods such as printing information including lot numbers on labels, etc. are used. We will also manage this information using a database to record and store it, a printer to print labels, and a reader to read the information.

Recording at the time of manufacturing has the hurdle of being time-consuming and costly for companies, but it also has the advantage of being able to understand and manage the flow of products, which can be used for inventory management and production adjustment.

It is possible to provide accurate explanations in response to inquiries from consumers, and even in the unlikely event that an accident occurs, it is possible to take prompt action, which will help gain the trust of consumers and improve the company's image.

Conclusion

What did you think. In Japan, there have been incidents in which food safety and security have been compromised, such as large-scale food poisoning accidents and pesticide residue problems.

As a result, an increasing number of consumers are concerned about food quality and origin when purchasing food due to concerns about safety, and food traceability is becoming increasingly important.

Consider traceability to increase your company's credibility.

⇒⇒ [Thorough explanation! ] What is the distribution and cold chain that maintains food quality?

⇒⇒Grace is 2020! ? What changes have been made with the enforcement of the Food Labeling Act?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Osechi remake dishes too! ] Introducing the method and recipe for freezing black beans](https://shunkashutou.com/wp-content/uploads/2023/09/9bcd5b0667eef32b7c7daf786e01172f.jpg)

![Introducing recipes and methods for freezing and thawing bananas [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/494e7567627fb35e47ee5cb0e06e142c.jpg)

![[Save onions in the freezer! ] Introducing storage methods and recipes with photos](https://shunkashutou.com/wp-content/uploads/2023/10/9d2c1259f1c42d7a0e3b61af361e5da8.jpg)

![[Rapid defrosting or slow defrosting] Unsure of which method? Read the complete guide on how to defrost](https://shunkashutou.com/wp-content/uploads/2024/04/ec8d0eb82bcecb5525574a8f72183a97.jpg)

![Explaining how to freeze garland chrysanthemums with photos! [Defrosting and storage period, 5 recipes]](https://shunkashutou.com/wp-content/uploads/2023/10/syungiku-catch-768x512-1.jpg)

![[Guide to handling frozen chicken for commercial use] How to thaw and how long it can be used after that](https://shunkashutou.com/wp-content/uploads/2018/04/IMG_15001.jpg)

![[Need to know] 7 points to thaw frozen crab deliciously](https://shunkashutou.com/wp-content/uploads/2023/08/394440560c05fb5b512d75b81a3fae4f.jpg)

![[Can it be frozen? ] Introducing recipes and methods for freezing avocados!](https://shunkashutou.com/wp-content/uploads/2023/07/7b25b2d45ff983fca2a15b6ad7edf369-1.jpg)

![[It's good to know! ] Introducing how to freeze curry, how long to keep it frozen, and how to thaw it |](https://shunkashutou.com/wp-content/uploads/2023/08/5de5495c896622dc896a8f23d9528300.jpg)

![[Introducing tricks and time-saving techniques! ] How to freeze ginger-yaki, carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/10/ef145c31655c5774469e05b5e892207b.jpg)

![[How long does it last? ] How to freeze cooked rice and how long it can be stored](https://shunkashutou.com/wp-content/uploads/2023/10/7e31499b015d58f220536e3274a41bf2.jpg)

![[Easy and recommended] 9 benefits of online supermarkets and 5 things to note](https://shunkashutou.com/wp-content/uploads/2023/09/netsuper-624x445-1.jpg)