[Easy installation and bulk storage] Prefabricated freezer functions and prices

This is a cold storage facility that is installed by combining prefabricated panels.

It is easy to install, and you can freely decide on the size and floor plan to suit your convenience.

It is possible to make effective use of space and expand as needed.

This system is used in a variety of locations, including food processing plants, food manufacturers, and restaurants, as it allows large amounts of food to be frozen and stored in bulk in preparation for increased production.

目次

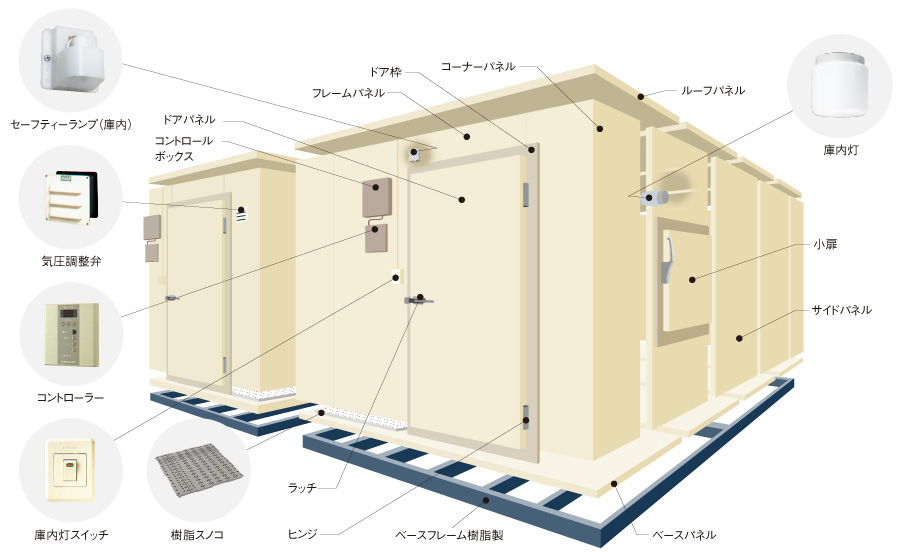

Free combination! Prefab freezer features

Source: http://www.hoshizaki.co.jp/p/prefab/kozo/index.html

A prefab freezer is a storage space for storing frozen foods.

A room is created by combining prefabricated panels, and the room is cooled using a cooling device similar to a typical air conditioner.

Since it is installed in combination with urethane foam insulation panels using insulation materials such as rigid polyurethane foam, it has excellent airtightness.

The temperature setting for prefabricated freezers is approximately -25℃ to -15℃. The temperature can be set according to the purpose, and food can be preserved through thorough temperature control.

In addition, since panels can be combined depending on the purpose, you can create a room by freely setting the height, floor area, size, etc.

You can also add more units to suit your needs or business expansion.

In this way, you can freely assemble and create panels, so you can install it anywhere, such as in a factory room or a warehouse.

Even if a factory or store is relocated, it can be easily reinstalled by removing the panels and reassembling them.

Since it is possible to store large quantities of frozen meat, seafood, and frozen processed foods, it has been introduced by butcher shops, seafood brokers, food manufacturers, inns, and hotels.

Not only can they store larger amounts of food than commercial freezers, they also have the advantage of making more efficient use of space and reducing warehouse rental and transportation costs.

In addition to prefabricated freezers for storing food frozen, there are also prefab refrigerators for storing food refrigerated. Prefabricated refrigerators are used for cold storage of food and beverages such as vegetables and rice, low-temperature storage of brown rice, and wine storage.

In addition to food, they can also be used as cold storage for plants such as flowers.

By installing multiple prefabricated freezers and prefabricated refrigerators, it is possible to set the temperature according to the purpose and store food in optimal conditions.

You can also protect your food by moving it to another room in case the cooler breaks down.

Since food can be stored at a temperature between -25°C and 25°C, it has been introduced in a variety of places, including food processing plants, restaurants, and supermarkets.

Prefab freezer price range

Source: http://www.hoshizaki.co.jp/p/prefab/

The price of prefabricated freezers varies depending on the size of tsubo, ranging from 0.5 tsubo to more than 100 tsubo.

The price is around 400,000 to 500,000 yen for 0.5 tsubo. If the size is 3 or 4 tsubo, it often costs more than 1 million yen.

If it is a small type (approximately up to 3 tsubo in size) with an integrated refrigerator, it can be installed easily and at a low cost. It can be installed on the same day, minimizing disruption to other operations.

Some people choose to install panels without having to hire a contractor, as there is no need for any construction work just by assembling the panels according to the instructions. That said, it can be difficult if you are not used to it, so most people prefer to hire a professional.

If the size is large, the refrigerator will be a separate type that is placed outside the prefabricated warehouse, so construction will be required for installation.

Depending on the manufacturer or distributor, some prices may include panel delivery, assembly work, lighting installation, installation, test run, etc., and others may not.

The amount of additional costs will vary depending on the contractor, so please check how much the installation will cost when getting an estimate.

Additionally, electric doors, slopes, air curtains, etc. can be added as options, allowing for various combinations depending on how you use it.

For example, if the door is opened and closed frequently, the temperature inside the prefabricated refrigerator tends to rise, so installing an air curtain or front chamber can prevent the temperature inside the refrigerator from rising.

Also, if you use a trolley to take food in and out, it would be convenient if it had a ramp.

For storing food at low temperatures! Introduction example of prefabricated freezers

Source: https://www.eco-plan.info/gallery/1766/

Prefabricated freezers have been introduced in various businesses, but I would like to take a look at specific examples of how they are used.

Introduction example 1 Barbecue service at a park office

Introduced to store ingredients when starting a barbecue service business in a park.

It is custom-made and can be freely adjusted in size and shape, so it can be installed in any location.

Installation can be completed in less than a day, so even offices that operate 365 days a year can install it without disrupting other operations.

By using it in conjunction with a prefabricated refrigerator, you can store not only barbecue ingredients but also drinks.

You can expand the space when demand increases, so you can use it to meet future needs.

Introduction example 2 Deli food manufacturer

A delicatessen food manufacturer took the opportunity of moving to a new factory and introduced prefabricated refrigerators and prefabricated freezers.

Since it can be stored at the optimal temperature setting according to the purpose and food, it can be used for a variety of purposes, such as low-temperature storage for ingredients and frozen storage for manufactured products.

The refrigeration and freezing space has been increased by approximately three times compared to the previous model, making it possible to store more food. In addition, raw materials that were previously kept in storage warehouses outside the factory can now be stored in bulk, improving work efficiency.

We were able to increase the number of production lines and set up a system for increasing production.

Introduction example 3 Sake brewery manufacturer

Sake brewers have introduced it as a low-temperature storage to maintain the quality of their sake.

Sake is difficult to store because it is easily affected by temperature and light. In order to maintain the quality of the sake produced, it must be stored in low-temperature storage before being shipped.

Prefabricated freezers take up more space, allowing you to store more alcohol.

Additionally, if you want to expand the space, you can add more units, so you can respond when expanding your production system.

Introduction example 4 Food processing manufacturer

Food processing manufacturers that use ingredients produced in Shinshu and Nagano prefectures have introduced many prefabricated refrigerators and prefabricated freezers.

We use it as a storage area for ingredients in order to make the most of the ingredients and create high-quality products. You can store food in bulk according to your needs, including refrigerated and frozen storage.

Since ingredients can be stored under strict hygiene management, it is possible to produce products with a focus on deliciousness and quality.

Conclusion

Prefabricated freezers can store larger amounts of food than commercial freezers, and can be installed freely to suit how you use them.

It can be expanded as needed and can be used for a wide range of purposes.

Why not consider a prefab freezer to store frozen foods?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![Introducing how to freeze fried chicken and a delicious recipe [Explaining tricks and techniques]](https://shunkashutou.com/wp-content/uploads/2023/09/2d15a108b8d7de5b4811f69c9bc8b8f1.jpg)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2016/03/99093c5fe8b0d716c39df907616e4a96.jpg)

![[Thorough guide to preserving meat] Preservation methods, expiration dates, thawing methods, rapid freezing](https://shunkashutou.com/wp-content/uploads/2023/09/ec61889773cfed9c75aa97d9ca6c96dd-1.jpg)

![[Which products are popular? ! ] Recommended frozen food ranking](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-ranking-1024x682-1.jpg)

![[Achieving low cost and high quality] The problems of pubs can be solved with a quick freezer!](https://shunkashutou.com/wp-content/uploads/2016/02/11d55612344a4cbad2ad506ae700c81b.jpg)

![[For the lunch box manufacturing industry] Business issues can be solved by using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/04/f93f171f5d29bdb15c4b8d06e244b002.jpg)