Introducing recommended models and examples of flash freezers! There is also information on useful subsidies.

Flash freezers are attracting attention these days.

Because it can be frozen without sacrificing quality, it has begun to be used by various companies in the food industry, including restaurants, seafood, meat, food manufacturers, and accommodation facilities.

The benefits are very large, with expected effects such as ``increasing sales,'' ``being able to purchase items without worrying about expiration dates,'' and ``reforming work styles through advance manufacturing and preparation.''

In addition, there are various types of flash freezers, such as air freezing types, liquid freezing types, and special method types, so it is very important to choose the most suitable one.

On this page, an expert provides a thorough explanation of flash freezers. We will explain what a flash freezer is, how it can maintain the quality of food, as well as the benefits and examples of its introduction, prices, and information on subsidies that can be introduced at a good deal.

目次

- 1Definition and mechanism of flash freezing

- 2 Difference between instant freezing and rapid freezing

- 3 Differences between commercial flash freezers and home freezers

- 4Foods that can now be instantly frozen

- 5 Advantages of flash freezing

- 6 Types of flash freezers

- 7 Recommended flash freezers

- 8 flash freezer price

- flash freezers9Subsidy is recommended for purchasing

- 10Conclusion

Definition and mechanism of flash freezing

Source: Japan Frozen Foods Association

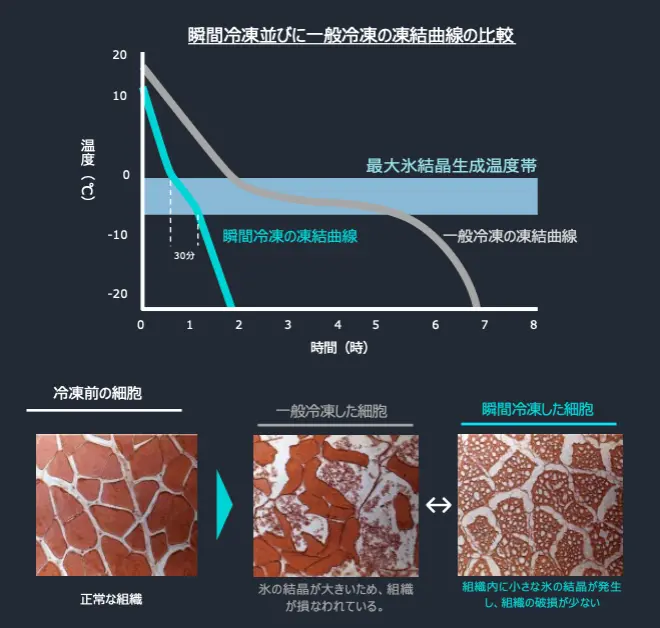

Flash freezing is a device that allows food to be frozen quickly without destroying the cells of the food or changing its quality. Although the term is not strictly defined, the rough standard for flash freezing is whether it can pass through the temperature range of -1℃ to -5℃, where water turns into ice, within 30 minutes.

If you freeze food slowly over a long period of time, the water in the food turns into ice, creating large ice crystals that can damage cells, resulting in drips, discoloration, and odors.

On the other hand, flash freezing produces fine ice crystals, which prevents damage to cells and allows freezing without sacrificing quality.

Difference between flash freezing and rapid freezing

So far we have explained about flash freezing, but you may also have the opportunity to know the keyword "rapid freezing" using a similar expression.

Actually, flash freezing and rapid freezing are both keywords used, but they must have different meanings. The current situation is that there are multiple ways to express something, and the expression used differs depending on the person using it.

[Quick freezing technology]

"Flash freezing", "rapid freezing", "quick freezing", "flash freezing"

[Equipment (machine) for quick freezing]

"Flash Freezer", "Flash Freezer", "Flash Freezer", "Flash Freezer", "Rapid rapid freezer", "Rapid Freezer", "Shock Freezer"

Some people find it difficult to understand, but basically they all refer to the same thing. Among them, the most popular is called "rapid freezing" or "rapid freezer."

Some people call it a "blast chiller". "Blast chiller" refers to a commercial cooling machine (a technology/machine that captures the rough heat of food), and is technically a different product because the usage and mechanism are different.

Differences between commercial flash freezers and home freezers

Recently, advances have been made to the point where household refrigerators can freeze food deliciously, and major manufacturers are also releasing a variety of products and technologies.

So, what is the difference between this and a commercial flash freezer?

From here, we will explain the differences between home refrigeration and commercial flash freezers.

Home refrigerator/freezer

We take two approaches to freezing food with good quality in home refrigerators and freezers.

The first method is to freeze as quickly as possible, approaching rapid freezing.

The temperature of a typical household freezer is -18℃, and it is difficult to lower the temperature further than that, so we use a method to cool things down faster by increasing thermal conductivity.

By placing food on a metal plate with high thermal conductivity (ability to transmit temperature, ease of transmitting heat) and freezing the food, or by blowing cold air onto the food, the temperature can be lowered more efficiently than normal freezing. It can be cooled down quickly.

However, it often takes several hours to freeze the food, and as mentioned in the opening chapter, it is currently difficult to freeze the food within 30 minutes using this method.

Another method is to not freeze it completely.

Mitsubishi's supercool freezing uses a method of freezing at -7℃, and Panasonic's partial freezing uses a method of freezing at -3℃. The temperature settings and techniques used vary, but the common thing is that they are not completely frozen to prevent large ice crystals from forming.

Since it is not completely frozen, it cannot be stored for a long time at the frozen level, but it can be stored for up to 3 weeks while maintaining its deliciousness.

commercial flash freezer

Unlike home-use flash freezers, commercial flash freezers are designed to maintain quality by flash freezing. Also, the amount to be frozen will be larger compared to freezing at home.

Many of our products have temperatures below -30℃ and are equipped with powerful engines, so they can be flash frozen within 30 minutes.

Therefore, by using a commercial flash freezer, you can freeze foods that could not be frozen before.

From here, we will introduce what kinds of products can actually be frozen.

Foods that can now be flash frozen

What kind of foods can be frozen?

Here are some examples of actual freezing.

seafood

Red fish, blue fish, white fish, shellfish, crustaceans, etc. are generally very reproducible with flash freezing.

Even tuna, bonito, and yellowtail, which are said to be particularly susceptible to discoloration, will not discolor, and will not drip even after thawing.

In addition, we can freeze whole fish, fillets, and sliced sashimi in a variety of ways.

Rice (sushi, etc.)

Rice is also very compatible with flash freezing.

Very good results have been obtained even with sushi, which contains rice and is particularly difficult to flash freeze. In fact, it has been used in sushi restaurants that have earned Michelin stars and have a customer spend of several tens of thousands of yen.

Fried food

Fried foods can also be flash frozen.

Foods can be frozen not only before they are fried, but also after they are fried.

By using a model that can flash-freeze hot, freshly-fried ingredients without cooling them, we are able to create products that preserve the crispiness and juiciness of freshly-fried foods and can be easily thawed and served.

As we have introduced so far, advances in flash freezer technology have made it possible to freeze foods that previously could not be frozen.

Flash freezing allows products to be stored for long periods of time without compromising quality, which not only eliminates waste, but also has many success stories such as resolving labor shortages and increasing sales.

In the next chapter, we will introduce the benefits of flash freezing machines that will lead to success.

Advantages of flash freezing

What are the actual benefits of flash freezing?

Here we will introduce the following three benefits.

① Increase sales

The first advantage of using a flash freezer is that it can be expected to increase sales.

By creating new products using flash freezing, you can create new sales pillars such as mail order, takeout, and wholesale sales.

In addition, if you stock products by freezing them, there will be no loss, so you can manage your inventory with ease. You can eliminate the opportunity loss of not being able to sell something because there is a demand for it but there is no stock.

②You can purchase without worrying about expiration dates

The second advantage of flash freezing is that you can purchase ingredients without worrying about expiration dates.

Flash freezing allows you to preserve food for a long time without sacrificing its quality.

Therefore, we can purchase high-quality ingredients at low prices by purchasing ingredients that are in season (high quality and cheap), purchasing ingredients that are only available at certain times of the year, and purchasing in bulk. It is possible to provide.

You can expect effects such as ``improving the quality of the products you provide'' and ``reducing purchasing costs and increasing profit margins.''

③ Work style reform can be realized through advance manufacturing and preparation.

The third benefit of flash freezing is that it enables work style reforms by changing the timing of product manufacturing and preparation.

By using a flash freezer, you can flash freeze products that have been manufactured and prepared in advance, then thaw and serve them when you want to use them.

We will introduce two typical usage methods.

[Event the workload during busy and off-season periods]

The first is to equalize the workload during busy and off-season periods.

When demand concentrates during certain periods, such as New Year's and mid-year holidays, the gap between the busy season and the off-season becomes larger, and working hours during the busy season increase, creating a burden. It will also be difficult to attract people who can work for a short period of time.

If you manufacture and prepare food in advance during the off-season to coincide with the busy season and flash freeze it, you can fill the gap between the busy and off-season.

[Reducing early morning and late night work]

The second is to reduce early morning and late night work.

When providing products for lunch, such as catered lunch boxes, the preparation is often done late at night the day before or early in the morning on the day of the meal.

By preparing the food in advance and simply thawing it the evening of the previous day or the morning of the same day, it is possible to reduce early morning and late night work.

There are many examples of work style reforms that reduce the burden on employees, increasing retention rates and successfully reducing recruitment and training costs.

As introduced above, flash freezing has many advantages and can be used in a variety of ways. Therefore, it has been introduced in a variety of industries, including restaurants, seafood, meat, and food manufacturers.

So, when it comes time to introduce a flash freezer, what kind of flash freezer is best?

Here we will introduce the types of flash freezers.

Types of flash freezers

There are different types of flash freezers based on different principles.

Here we will introduce the principles of each.

Air freezing type (air blast type)

Currently, this is the most popular freezing method. By exposing the food to cold air of around -35℃, heat is removed from the food and the food is instantly frozen in a short period of time.

There are also air freezing type flash freezers with various features.

There are some types that allow you to freeze ingredients even if they are naked by preventing them from drying out, and some that allow you to freeze freshly cooked ingredients as they are.

Liquid freezing type (liquid type/alcohol type)

Cool a liquid that does not freeze (antifreeze) such as alcohol to a temperature of -10℃ to -35℃, and then submerge the food in it to flash freeze it.

Liquids have high thermal conductivity (ability to transmit temperature), so they freeze quickly.

Since food is soaked in liquid such as alcohol and then frozen, it is necessary to vacuum package the food in advance and wipe off the liquid, which is time-consuming and costly.

Contact freezing type (contact type)

This is a type of flat tank where food is sandwiched between cold metal plates and flash frozen by direct contact.

Because the flat tank comes into direct contact with the food, it is characterized by high heat exchange efficiency. In addition, by applying pressure when sandwiching the food, you can mold it to the desired thickness.

Because the flat tank comes into direct contact with the food, vacuum packaging is required in advance, similar to the liquid freezing type.

liquefied gas type

This type uses liquefied gas such as liquefied nitrogen or liquefied carbon dioxide to flash freeze. Liquefied carbon dioxide gas is flash-frozen by exposing the food to a refrigerator at -78.5℃ and liquefied nitrogen at -196℃.

Although the extremely low temperature allows the food to freeze quickly, if the temperature is too low, it can also cause damage such as splitting of the meat, so there are many differences in the suitability of the food depending on the ingredients.

It is not a very common type because it is difficult to handle.

Special method type

We introduce special method types that do not fit into any of the four types introduced so far.

It achieves high-quality freezing by using a mechanism that uses magnetic flux, electromagnetic waves, magnetic fields, vibrations, etc. to freeze water molecules in the best possible state.

Because they are equipped with mechanisms such as magnetic flux, electromagnetic waves, magnetic fields, and vibrations, costs tend to increase.

Regarding magnetic fields, experimental verification has been carried out, and it has been concluded that when freezing is performed in a flash refrigerator under the same conditions, there is no difference in the size of ice crystals depending on the presence or absence of a magnetic field, which is controversial. This is the principle.

As you can see, there are various principles of flash freezing machines, so it is important to choose one that suits the food to be frozen and the usage scene.

However, there are many people who don't know which flash freezer is best among the various flash freezers, so we will introduce some recommended models in the next chapter.

Recommended flash freezer

Here we will introduce recommended models for the air freezing type (air blast type) and liquid freezing type (liquid/alcohol type), which are mainstream as of July 2023.

Recommended model ①: Artlock freezer (air freezing type)

Artlock Freezer is the latest flash freezer equipped with a micro-wind system, AI smart freeze, and anti-frost mechanism.

It can freeze food at the industry's highest level of freezing speed and prevent food from drying out.

In addition, since ingredients at any temperature can be flash frozen, it is also possible to freeze freshly prepared ingredients as they are.

There are various specifications available, from small models to large models that can freeze around 500 kg per hour. Custom-made machines are also available.

Recommended model ②: Rejoice freezer (liquid freezing type)

Rejoice Freezer is a liquid freezer (alcohol freezer) that freezes food at -35℃.

It is an excellent product in terms of cost performance and workability.

We have a variety of sizes available, from small ones that run on a 100V power supply, so you can choose the model of the most suitable size.

Flash freezer price

We have introduced the instant freezer so far, but how much does it cost?

The price varies greatly depending on the principle and specifications of the flash freezer, especially in proportion to the amount of frozen processing (amount of frozen water per hour).

The smallest model starts at around 1 million yen.

Naturally, the higher the performance, the higher the price, so it is important to consider the scale of your business and costs when choosing the most suitable model.

Subsidies are recommended for purchasing flash freezers.

Flash freezers are not cheap purchases.

The best way to introduce such a flash freezer at a reasonable price is to utilize subsidies and grants.

Particularly popular examples of use are ``Business Restructuring Subsidy'' and ``Manufacturing Subsidy.'' The subsidy rate is high (up to 2/3 of the investment amount is subsidized), and the subsidy amount ranges from 1 million yen to 100 million yen, and can be used for projects of various sizes.

The conditions for eligibility for subsidies are subject to change from time to time, and many companies are now able to use the subsidy even if they were unable to do so in the past, so we recommend that those who wish to use the subsidy check again.

In addition, we have a track record of introducing our products through various subsidies and grants, including subsidies due to rising raw material prices and subsidies provided by prefectures, municipalities, etc.

Conclusion

What did you think?

Flash freezing allows you to preserve a variety of foods for long periods of time without sacrificing quality.

As a result, it is possible to achieve effects such as ``increasing sales,'' ``being able to purchase products without worrying about expiration dates,'' and ``achieving work style reforms through advance manufacturing and preparation.''

When purchasing, we recommend using subsidies to get a better deal.

Start by performing a freezing test and selecting the flash freezer that best suits your food and business.

In addition to freezing tests, we also offer online introductions, so please feel free to contact us.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Explanation with photos] How to freeze salmon fillets, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/fb96564ba06a8cc88a72f0c971ad54e5.jpg)

![[Should be frozen! ? ] How to freeze and thaw bread, 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/4691acc32cab80284fa0cddf72d58e95.jpg)

![[Thorough Guide to Preserving Sweets] Introducing the freezing method, storage period, and thawing method in detail!](https://shunkashutou.com/wp-content/uploads/2023/10/bffcbc0b6e79bb1af6e05b930e11e949.jpg)

![[Can it be frozen? ] How to freeze and thaw okonomiyaki, arrangement recipe!](https://shunkashutou.com/wp-content/uploads/2024/01/58bc763c02f23a2a6442d6449853a67b.jpg)

![[Various recipes] 3 tips for using frozen minced meat deliciously](https://shunkashutou.com/wp-content/uploads/2023/08/e9b2fc255393916ab79ea8b7fa0807d3.jpg)

![[Explanation with photos] How to freeze octopus, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/5128a2b3fa3cc254cffab87821372215.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Solving issues in the retail industry] Liquid freezing machines that should be introduced in supermarkets](https://shunkashutou.com/wp-content/uploads/2015/09/60172f0f261fd750c4016165c3c56cc8.jpg)

![[Increase sales! ] Three reasons why ramen restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2016/04/ra-men-reitou.jpg)

![[Achieving instant freezing at home] The evolving freezing function of home refrigerators](https://shunkashutou.com/wp-content/uploads/2015/10/93e403bcf18bda6b2d63c7c74fdef064.jpg)

![Introducing how to freeze and thaw whitebait, as well as recipes for its use [Full of nutrition! ]](https://shunkashutou.com/wp-content/uploads/2023/10/04d15012ec36f91a5574f63dfa9d4771.jpg)

![[Freezing for a long time] 3 points to keep in mind when preserving vegetables](https://shunkashutou.com/wp-content/uploads/2023/08/5a2668284473e2bd93d9ade88bad2c0b.jpg)

![[Explanation with photos! ] Introducing the method and recipe for freezing komatsuna](https://shunkashutou.com/wp-content/uploads/2023/09/5d2a19a6e6cfb5ad0329d8fce162f292.jpg)

![[Dramatically extends the shelf life of vegetables! ] What is blanching process?](https://shunkashutou.com/wp-content/uploads/2023/07/8fce721a563a0e86a740b4d11dc63766.jpg)

![[Explanation with photos! ] How to freeze pork, expiration date, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/8688cd28f298c3180c30169cec815293.jpg)

![[Freezing Preservation Tips Series] A good way to freeze cabbage! Tips to make it last longer and taste better](https://shunkashutou.com/wp-content/uploads/2023/08/3ac1c4816b324c68e34ebf092e631127.jpg)

![[Must-see for bakers] 6 reasons why bakeries should use rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/02/f92a102c9d3cc8c63dc7e509ce6d35d2.jpg)