flash freezing demonstration Freezing and thawing of fried chicken (short term)

This time, we conducted a freezing and thawing experiment on fried chicken.

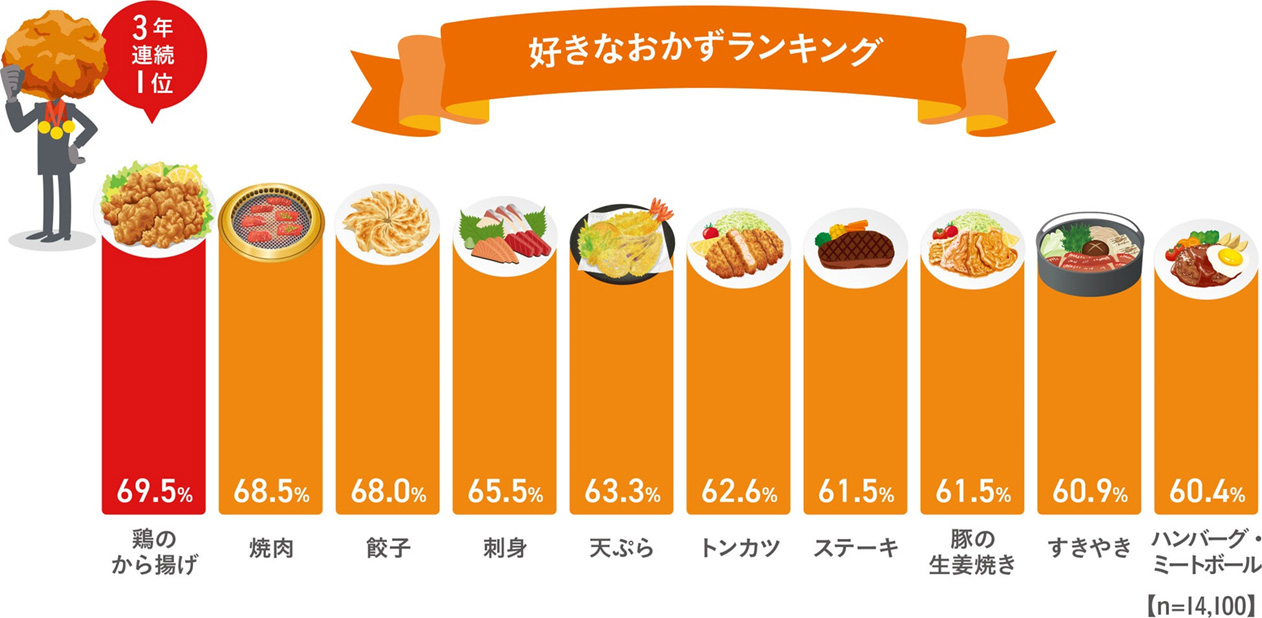

Karaage is an indispensable side dish for lunch boxes, and has been ranked number one for three years in a row in the ranking of favorite side dishes.

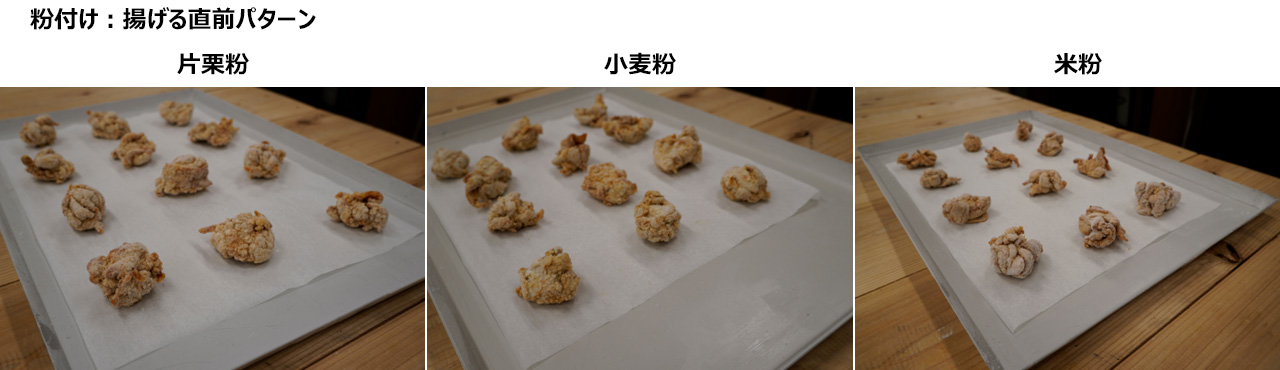

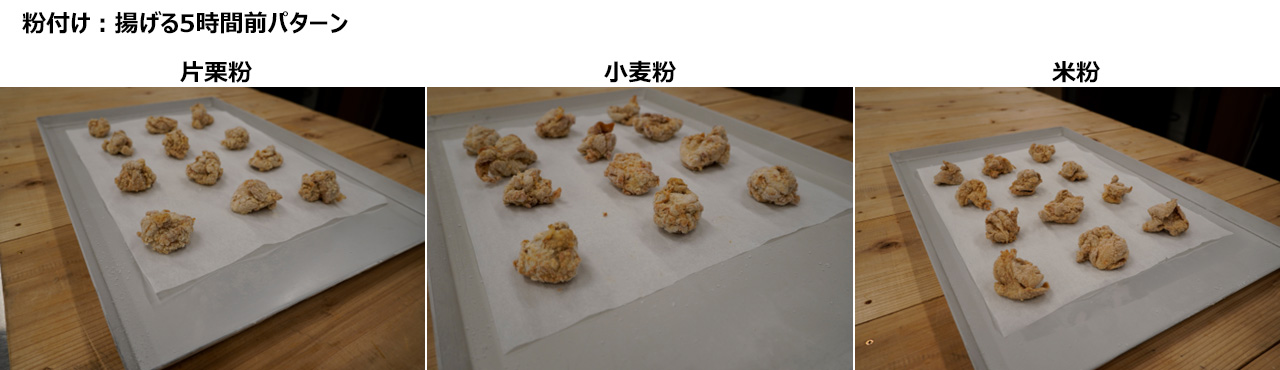

This time, with the image of caterers and particular karaage restaurants, we will be researching karaage flour suitable for freezing and thawing.There are 3 types of flour: potato starch, wheat flour, and rice flour, and 2 different timings for adding flour. We experimented with a total of 6 patterns (just before frying and 5 hours before frying).

Here are the main conditions for this experiment.

Ingredient selection: Type of flour (potato starch, wheat flour, rice flour)

Freezing conditions: Timing of flouring (just before frying/5 hours before frying)

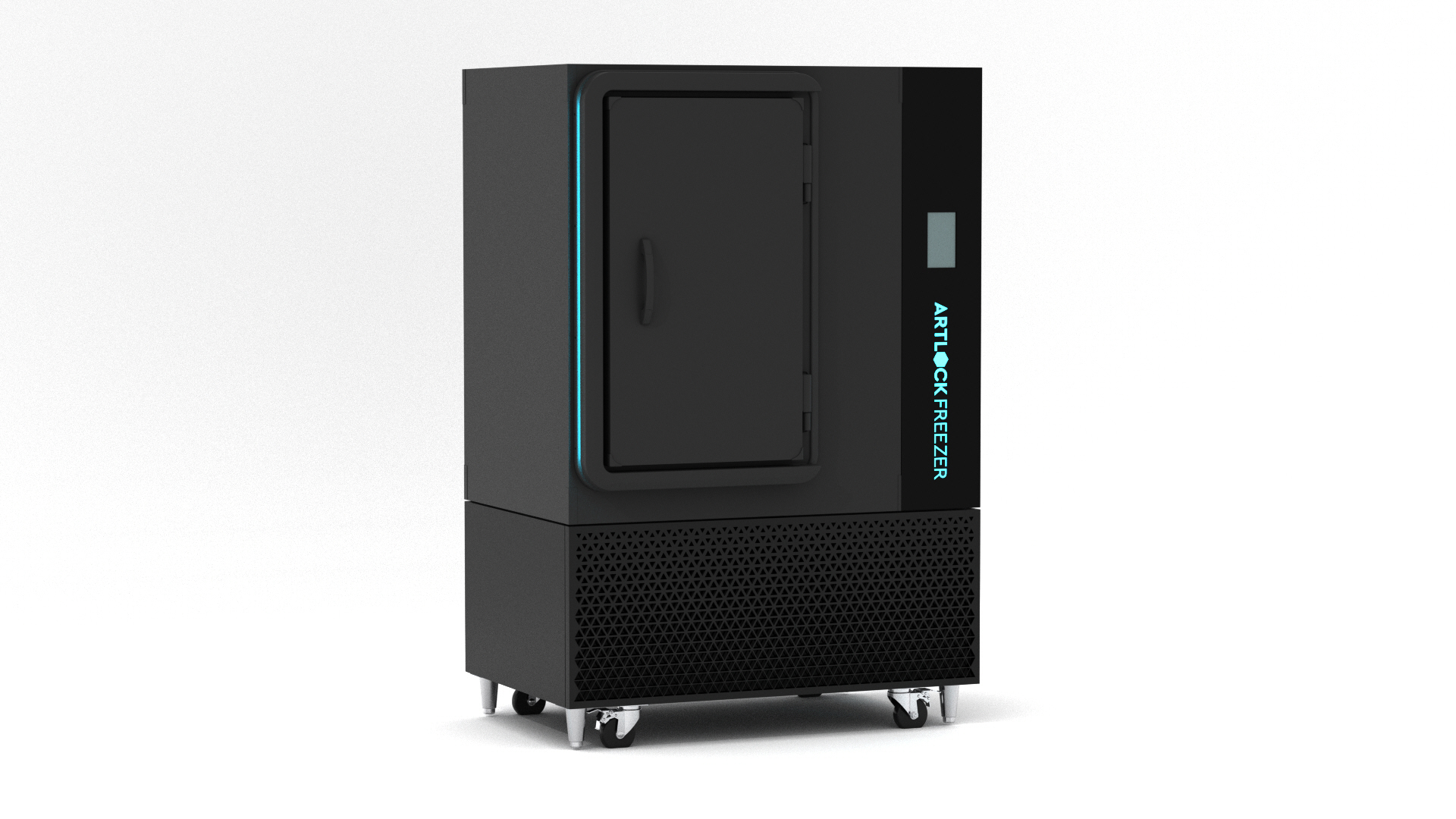

Freezing method: Artlock freezer (can be stored while freshly fried)

Storage method: -20℃ freezer for 2 weeks

Defrosting method: Microwave, refrigerator thawing, steam convection oven thawing

Condition before and after freezing

Before freezing

This time, we will flash freezing chicken arranged on a French baking sheet using an Artlock freezer.

The Artlock Freezer is rapid freezer is extremely suitable for producing frozen karaage that maintains the deliciousness of freshly fried chicken.

One of the reasons for this is that because the air is frozen, hot, freshly fried karaage can be placed in the freezer after draining a little of the oil.

A big advantage is that you can maintain the juiciness of the fried chicken by adding it while piping hot.

If you remove the rough heat before putting it in the freezer, excess moisture will evaporate, which can cause it to lose its juiciness and become dry, but that process is unnecessary.

This time, it took only 1 hour to freeze each 50g piece from a core temperature of about 77℃ to -18℃.

In terms of freezing time, the Artlock Freezer is a very efficient rapid freezer.

After freezing

Storage after freezing

This time as well, we are using a high-barrier film (low oxygen permeability) that allows for the highest quality frozen storage, and we are vacuum-processing it with a vacuum packaging machine to about 95% (to the extent that it will not collapse while keeping an eye on it) and storing it!

The Artlock Freezer can freeze food in its bare state without drying it, allowing vacuum processing after freezing.

Foods after freezing are harder than before freezing, so even if vacuum processing is performed at a relatively high degree of vacuum of 95%, the food will not be crushed and its quality will not deteriorate.

As a result, by storing food under a high degree of vacuum, the contact of food with oxygen can be minimized, and high quality can be maintained for a longer period of time.

Thawing

In this experiment, thawing was performed under the following three conditions.

Here is a photo before thawing.

Upper row: Pattern just before dusting, from left: potato starch, wheat flour, rice flour

Lower row: Pattern after 5 hours of powdering, from left: potato starch, wheat flour, rice flour

-Refrigerated thawing: 10℃ temperature range, thawing in about 3 and a half hours

・ Steam convection oven thawing: Combi mode humidity 60%, thawing in 6-7 minutes

・ Microwave thawing: 500W 3 minutes thawing

Sensory evaluation results

- About thawing methods: Steam convection oven thawing > Refrigerating thawing > Microwave thawing

If you defrost it in the microwave + use a toaster oven, you can recreate the crispy texture of the batter!

- About the batter: Potato starch/wheat flour > rice flour

Rice flour tastes delicious when freshly fried, but it has a sticky taste that sticks to your teeth, so we don't recommend using rice flour alone!

- Regarding the timing of powdering: As per your preference.

Please contact us for detailed results of this experiment.

Conclusion

This time, we reported on the results of a freezing and thawing experiment on fried chicken.

We used three types of flour: potato starch, wheat flour, and rice flour, and applied the flour at two different times: immediately before frying and 5 hours before frying, for a total of 6 patterns.

By freezing the food using the Artlock Freezer, I was able to freeze it while it was freshly fried and piping hot.

The time required for freezing is approximately 1 hour, and it is considered that extremely efficient operation is possible.

In addition, since food can be frozen without being dried bare, it can be packaged with a relatively high degree of vacuum even during vacuum processing after freezing, and it is expected that high quality will be maintained for a long period of time.

The results of the sensory evaluation after thawing are as follows.

- Defrosting method: Steam convection oven thawing > Refrigerating thawing > Microwave thawing

- For batter, use potato starch/wheat flour > rice flour

- There is no particular difference in the timing of powder application.

Also, by defrosting in the microwave and using a toaster oven, I was able to recreate the crispy texture of the batter!

Furthermore, we found that while rice flour batter is delicious when fried, it becomes soggy and sticks to your teeth, so it is not recommended to use rice flour alone.

In this article, we have briefly explained the experimental results, but if you would like more detailed experimental results, please contact us.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Lunch boxes are easy! ] Techniques and recipes for effectively using frozen side dishes](https://shunkashutou.com/wp-content/uploads/2023/07/reitou-bento-1024x682-1.jpg)

![[Delicious frozen foods] How to use them in lunch boxes, dinners, and snacks](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-1024x683-1.jpg)

![[Secret Technique] Introducing the freezing preservation and remake recipe of Kinpira Burdock!](https://shunkashutou.com/wp-content/uploads/2023/09/4c4b704274331befeed83cc4493acb75-1.jpg)

![[Can it be frozen? ] How to freeze cabbage rolls, storage period, and recipe](https://shunkashutou.com/wp-content/uploads/2023/10/f5c1db9a17ef7843ffd45f5ccb160ed5.jpg)

![[Can it be frozen? ] How to freeze mashed potatoes, how long they can be stored, and how to use them](https://shunkashutou.com/wp-content/uploads/2023/09/b7f3f25102051473b7c2f9452840a6f4.jpg)

![[Can it be frozen? ] How to freeze dried daikon radish and arrange recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/84f89f802d6869949972432e7b3be19c.jpg)

![How to freeze delicious strawberries and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/1509eaf30e7a2fc1b5bbc88ae15a4034-1.jpg)

![Introducing the method and recipe for freezing green onions [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/negi5-768x512-1.jpg)

![How to freeze celery, nutrition, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/serori-768x512-1.jpg)

![[Mass production and space saving] What is the secret of the spiral freezer structure?](https://shunkashutou.com/wp-content/uploads/2015/02/3d-sp.jpg)

![[Explanation with photos! ] How to freeze pork, expiration date, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/8688cd28f298c3180c30169cec815293.jpg)

![How to freeze/thaw turnips, storage period, and 5 recipes [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/eae0789d04cc4971cf4232963b4d2231-1.jpg)

![[Solving issues in the retail industry] Liquid freezing machines that should be introduced in supermarkets](https://shunkashutou.com/wp-content/uploads/2015/09/60172f0f261fd750c4016165c3c56cc8.jpg)

![[Freezing boiled food] rapid freezing demo](https://shunkashutou.com/wp-content/uploads/2016/10/4739208abfe6e2e63a43347c1598e991.webp)

![[Tips for making egg rolls that can be frozen] Introducing freezing methods, storage periods, and recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/tamagoyaki-768x512-1.jpg)

![[Be good at saving money! ] Introducing the method and recipe for freezing fried rice](https://shunkashutou.com/wp-content/uploads/2023/10/mayo-tyahan-1024x768-1.jpg)

![[Explanation with photos] How to freeze winter melon, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/8c301e3fcfbb9c7f457d8b05dfea902d.jpg)

![[Explanation with photos] How to freeze octopus, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/5128a2b3fa3cc254cffab87821372215.jpg)

![[Explanation with photos! ] How to freeze mackerel fillets and 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/bf45f102162a8d43387d3a8d3e538034.jpg)

![[Explanation with photos! ] How to freeze green beans, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/f3dbbe5b1d05a50f514a833efdceced9.jpg)