What is a Cook-Chill system?

Did you know that Cook-Chill is a cooking method that allows you to cook food more safely and more efficiently?

Cook-Chill is one of the new cooking systems. After cooking the ingredients, they are quickly cooled and stored, then reheated and served at the appropriate timing.

Compared to the traditional "cook-serve" in which food is prepared and served immediately, it helps prevent food poisoning and improves efficiency.

"We're short-staffed, but we can not hire more staff."

“Unless you are the chef that created a specific item, you cannot serve the same item.”

These problems can be solved with a Cook-Chill system.

This cooking system is especially used in mass cooking such as school lunches, hospital food, central kitchens, and food factories, but recently, small-sized equipment has appeared, and Cook-Chill systems are widely adopted in restaurants, delicatessen stores, confectionery stores, etc.

In this article, we will discuss the Cook-Chill system, which is currently attracting attention as a new cooking system that is essential for preventing food poisoning and improving cooking efficiency.

We will explain the cook chill system in detail, including the advantages and disadvantages of its implementation, and actual examples.

If you don't know about the new cooking systems that are being widely adopted, you may want to read this article.

Please read until the end and hopefully it can help your store keep up with the times and solve its problems.

目次

- 1 New and popular cooking systems

- 2 What is Cook-Chill system? Differences with Cook-Serve

- 3 What are the benefits of the Cook-Chill system?

- 4 What is the temperature control and storage period of food using the Cook-Chill system?

- 5 Cook-chill implementation examples

- 6 Disadvantages and problems of a Cook-Chill system

- 7 What is the installation cost of the Cook-Chill system?

- 8 How to use the Cook-Chill system?

- 9What is the new trend of Cook-Freeze?

- 10Conclusion

New and popular cooking systems

Long working hours and early morning shifts due to chronic labor shortages are issues faced by many food businesses.

The individualization of cooking, such as menus that can only be prepared by specific chefs, is also an issue that impacts efficiency.

New cooking systems have been attracting attention in recent years as solutions to those issues.

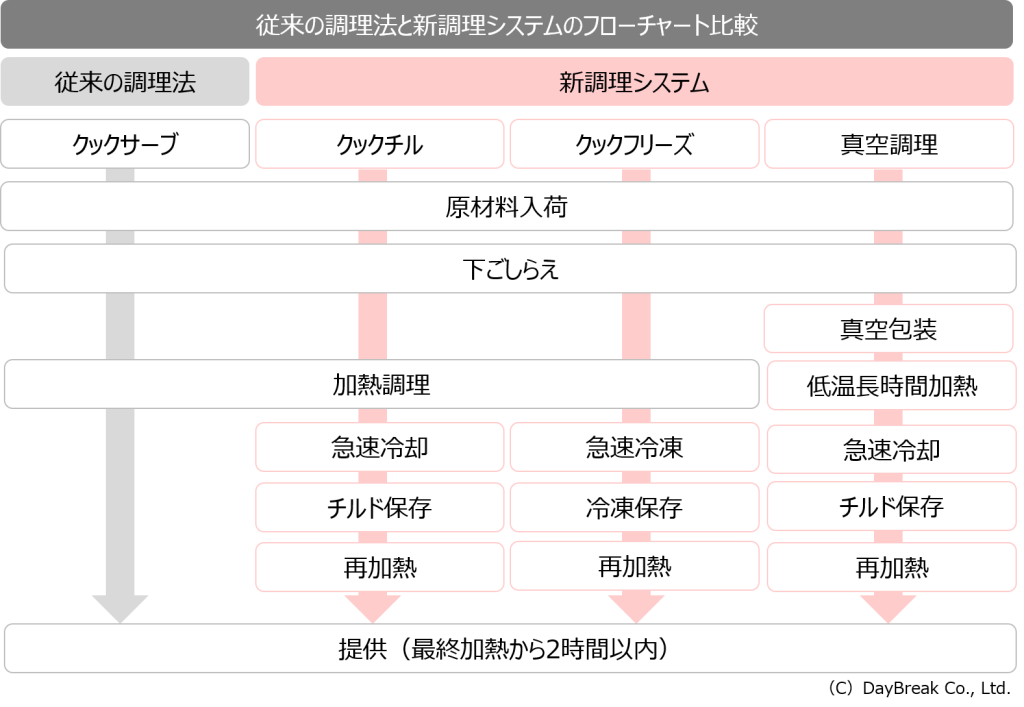

There are three main types of new cooking systems: Cook-Chill, sous-vide cooking, and Cook-Freeze.

This diagram is a flowchart from cooking to serving compared to traditional Cook-Serve.

All of these cooking systems are useful for resolving labor shortages and increasing efficiency, but this time we will focus on and explain the Cook-Chill system, which has become increasingly popular in recent years.

What is Cook-Chill System? Differences with Cook-Serve

First, let us define the Cook-Chill system.

Cook-Chill is a cooking method in which food is cooked and then quickly cooled (within 90 minutes at a core temperature of 3℃ or less), stored at a low temperature (0 to 3℃), and then reheated and served as needed. Food can be stored in Cook-Chill systems for up to 5 days starting from cooking days.

Cook-Chill is widely used in the food industry and medical institutions.

For example, in the food industry, companies that sell pre-cooked foods use it. In medical institutions, it is sometimes used for hospital meals and during emergency situations such as disasters.

How is it different from traditional cooking methods?

Traditional cooking involves heating and serving food immediately, just as you would normally do.

This cooking method is called Cook-Serve. Cook-Serve unfortunately had various disadvantages and problems.

●Disadvantages of the Cook-Serve system

- Food must be served within 2 hours after cooking

- Hygiene management is difficult

- Cannot be stored and is easily disposed of

- During peak hours, there is not enough staff to provide services in time.

- The only way to provide the same menu is to hire a specific chef full-time.

- Difficult to systemize/manualize cooking

Cook-Chill systems solve these problems.

Now, we will explain what kind of benefits Cook-Chill actually has and why it can solve such problems.

What are the benefits of the Cook-Chill system?

The process from cooking to serving is very different between the traditional cooking method Cook-Serve and the Cook-Chill system. This difference has four main benefits.

Advantage ① extremely safe (prevention of food poisoning)

In the Cook-Chill system, food is rapidly cooled so that it passes through the temperature range of 60 to 10° C, which is the temperature range where pathogenic bacteria and microorganisms can easily proliferate. This reduces the risk of food poisoning and ensures food safety.

Cook-Chill systems cool food quickly, slowing the growth of bacteria and keeping it fresh longer.

Additionally, food can be stored in a sealed container, extending its shelf life. By carefully managing the time and temperature according to regulations, it is possible to preserve the food for up to 5 days.

The food is reheated just before serving, so there is no need to touch it again. This means you can reduce the risk of food poisoning.

Advantage 2: increased efficiency

In the case of conventional Cook-Serve, cooking was concentrated during peak hours, which placed a burden on the cooks, by increasing the number of staff and preparing food early in the morning.

With a Cook-Chill system, the shelf life is significantly longer, up to 5 days, compared to Cook-Serve. You can cook according to peak hours and needs, by making extra dishes when you have free time for example.

Since you only need to reheat pre-cooked food, you can save a lot of time and effort in serving it. Cook-Chill makes cooking much more efficient.

Advantage 3: Stable quality (menu manual/systemization)

In the case of Cook-Serve, the taste varies depending on the skill and taste of the cook, and the problem was that it placed a burden on a particular cook.

On the other hand, by using a Cook-Chill system, recipes can be made into manuals and systematized, resulting in stable quality. This way, even if the chef that created the menu is not available, you can still recreate the same taste with the Cook-Chill system.

Cook-Chill systems are particularly useful in places where nutritional management and safety are important, such as school lunches, hospital meals, and elderly care facilities.

By adopting a Cook-Chill system, menus devised by registered dietitians are cooked and cooled in the central kitchen, and then reheated and plated in satellite kitchens (hospital and facility kitchens) to provide safe and delicious food.

Advantage ④ Cost reduction

The cook-chill system can reduce labor costs by leveling out work during peak hours and reducing the need to work on holidays.

Additionally, since it can be preserved, the frequency of transporting ingredients is reduced, reducing transportation costs. By planning your cooking, you can avoid wasting food and keep the cost of ingredients to the bare minimum.

Implementing a Cook-Chill system improves efficiency and reduces various costs.

The Cook-Chill system has four advantages: high safety, increased efficiency, stable quality, and reduced costs.

So, how does the Cook-Chill system work? We will explain the cooking process, temperature control, and storage period of food when using the Cook-Chill system.

What is the temperature control and storage period of food using the Cook-Chill system?

The Cook-Chill system improves the following five cooking processes.

preparation

Cutting ingredients, seasoning, etc. If you can improve your efficiency with a Cook-Chill system, you will be able to use your free time to prepare food.

Cooking

The food is heated and cooked until it is ready for serving. Even at the cooking stage, there is a way to further improve productivity and safety by using a steam convection oven, which uses steam and hot air to control heating temperature and time.

Rapid cooling

Transfer the cooked food to a hotel pan, etc., place it in a blast chiller, and rapidly cool it with cold air.

Cooling begins within 30 minutes of cooking and cools down to below 3℃ within 90 minutes.

Chilled storage

It can be stored for up to 5 days at a temperature range of 0-3℃.

Reheat and serve

Reheat at 75°C or above for at least 1 minute, plate and serve within 2 hours of final heating.

Next, let's take a look at examples of the Cook-Chill system being implemented in hospitals, school lunches, and restaurants.

Implementation examples

We will give you three examples that illustrate the changes brought about by the four benefits mentioned above.

Cook-chill system at a hospital

At one hospital, hospital food was served using traditional Cook-Serve methods, but there were problems such as food needing to be plated before serving, which led to a lack of time and the temperature dropping during serving.

So, when they transitioned to Cook-Chill, they were able to free up time by making plans and cooking in advance. Now that they can safely serve hot food, and patients are hapoy about the quality of food.

Cook-Chill system at a school lunch center

One school lunch center produces 10,000 school lunches a day, and staff work from early in the morning to prepare large quantities of food. Another problem was that the temperature would drop before transporting the meals to schools.

As a result of implementing the cook-chill system, it seems that the workload of the staff has been reduced because they have been able to preserve their food better, which means they no longer have to work from early in the morning. They also no longer have to worry about the temperature because you warm food up just before serving.

Cook-chill systems are especially useful in hospitals and school lunches, where large quantities of food are cooked and safety is important. Recently, Cook-Chill systems have been increasingly used not only by these businesses and food factories, but also by small-scale processors and restaurants due to their benefits such as increased efficiency and prevention of food poisoning.

Cook-Chill system at a restaurant

At some restaurants, they are extremely busy during lunch hours and on weekends, and the rest of the time is less intense. Only a few chefs are able to recreate the restaurant's food taste, and when they take days off, it was harder to maintain the food's quality.

Therefore, they transitioned to a cook-chill system, which made it possible to level out the work by making use of free time to prepare meals in a planned manner, and it is said to have solved the chronic labor shortage. The reliance on chefs has been reduced by creating recipe manuals that everyone can use.

By cooking in batches from 10am to 3 pm, a time where they could hire part-timers, recruitment has become smoother.

The Cook-Chill system has many advantages, but it has also some disadvantages.

Disadvantages and problems of a Cook-Chill system

In this article, we discussed the benefits of having a Cook-Chill system, but that is not all.

There are two things you need to be careful about when installing a Cook-Chill system.

It requires space

Rapid cooling is essential for a Cook-Chill system, which means a special machine called a blast chiller is required. To cook in large quantities, you need a fairly large blast chiller, which takes up a lot of space.

A large space is also required to store food at low temperatures after it has been rapidly cooled.

Not all menus are compatible with the Cook-Chill system

Cook-Chill systems involve rapid cooling and reheating processes, so some menus may not be compatible with them. Some foods, such as grilled, stir-fried, and deep-fried foods, do not go well together and it is difficult to maintain their quality once reheated.

We recommend researching the compatibility of the menu you want to use the Cook-Chill system with before investing in the equipment.

The Cook-Chill system has not only advantages but also disadvantages.

So, how much will it cost to install a cook chill system after understanding these points?

Next, we will explain the cost of installing a Cook-Chill system.

How much does it cost to install a cook chill system?

The mainstream equipment used in Cook-Chill systems are blast chillers, which cools with cold air.

The price of a blast chiller is more than 1 million yen even for a small machine (about 6,462 USD) , and more than 5 million yen for a large one (about 32,312 USD). If you want to keep the price down, second-hand items are also available at online auctions and second-hand specialty stores.

However, if it is a used product, the warranty period is short and there is a risk of incurring large repair costs in the event of a malfunction. Be sure to check the equipment's conditions and the warranty period.

In addition to the rapid cooling function, some blast chillers also have

- Equipped with a shock freeze function that allows you to freeze immediately after cooling.

- Ability to reheat up to 75℃

- Low temperature cooking function

Some machines are equipped with such functions, so if you use them properly, you can make your work even more efficient, and they may be useful for the Cook-Freeze system that we will discuss in this article.

So far, we have discussed the Cook-Chill system. The Cook-Chill system has many benefits such as preventing food poisoning and increasing efficiency, but recently there is a cooking method that has been attracting more attention than Cook-Chill.

This is one of the new cooking systems that I briefly mentioned at the beginning, Cook Freeze. Finally, we will explain the Cook-Freeze system.

How to use the Cook-Chill system?

The Cook-Chill system is a processing method that maintains high freshness and quality by rapidly cooling and preserving food.

The main ways to use the Cook-Chill system are summarized below.

- Ingredients selection

- Cooking method selection

- Cooling method

- Packaging method

- Storage method

Ingredients selection

When using a Cook-Chill system, select ingredients that are as fresh as possible to maintain freshness and quality.

They need to be cooled before cooking, so don't leave it them room temperature.

Cooking method selection

Cook-Chill systems require rapid cooling after cooking. Therefore, avoid cooking with high-heat such as boiling or stir-frying.

We recommend cooking methods with low temperatures, such as oven cooking or steaming.

Cooling method

It is important for Cook-Chill systems to cool food rapidly.

If you leave the food at room temperature after cooking, bacteria will grow. We recommend that you cool down your appliances by immersing them in water, immersing them in ice water, or using the cool-down function if your appliance has a cool-down function.

Packaging method

Cook-chill systems require highly hermetic packaging.

Use a highly airtight bag or container and seal it under vacuum.

Also, once you open the package, you can maintain its freshness and taste by eating it as soon as possible, rather than dividing it into several portions and eating it over a long period of time.

Storage method

To store food cooked with the Cook-Chill system, store it in the refrigerator or freezer.

If stored in the refrigerator, it can be stored for about a week.

If you store it in the freezer, it can be stored for a long time.

As discussed above, in order to make delicious food using the cook-chill system, it is very important to follow the correct usage instructions and store it safely.

What is the new trend of Cook-Freeze?

The Cook-Freeze system has recently attracted attention as a cooking method that is more efficient and has more benefits than the Cook-Chill system.

The Cook-Freeze system is a system that freezes food immediately after it is cooked (within 90 minutes at a core temperature of -5°C or below, within 120 minutes at -18°C or below). You can then store your food and reheat it whenever you need to.

Since the Cook-Freeze system stores products frozen, which significantly extends your food's shelf life to up to 8 weeks from the cooking date. This makes it even more efficient than a Cook-Chill system than extends the food's shelf life to up to 5 days.

Furthermore, because the expiry date is extended, the amount of food that can be delivered in one shipment can be further increased, reducing shipping costs. Due to increased efficiency, labor costs will also decrease, making it possible to reduce costs even more than with a Cook-Chill system.

In addition, typical frozen storage causes problems such as cell damage, resulting in a loss of taste and texture compared to before freezing.

Rapid or flash freezing technology solves this issue.

By using rapid or flash freezing technology, it is possible to reproduce the same taste and texture as before freezing in a short period of time. By using a Cook-Freeze system that incorporates rapid freezing, cooking becomes more efficient and cost-effective than a Cook-Chill system.

For example, in the case of foods that are mass-produced at a specific time, such as New Year's or Christmas dishes, using the Cook-Freeze system allows production to be planned several months in advance, reducing the burden of cooking while maintaining quality.

Recently, flash freezers have been developed that also serve as blast chillers and can rapid freezing freshly prepared food, eliminating the need for complicated processes such as removing residual heat.

Since the taste of freshly prepared food remains the same even after freezing and thawing, this new cooking system not only improves efficiency and cuts costs, but also helps develop new sales channels such as frozen food delivery.

Conclusion

We talked about the Cook-Chill system, which enables safer cooking and efficient meal delivery, based on its benefits and implementation examples.

The Cook-Chill system has the advantage of increasing efficiency and reducing costs due to the longer storage period, preventing food poisoning, and providing safer and more stable quality food.

We also briefly discussed Cook Freeze, which incorporates rapid or flash freezing, which can further extend the benefits of Cook-Chill.

We discussed how to use Cook-Chill to maintain freshness and quality. There are some tips for using Cook Chill.

In recent years, new cooking systems such as the Cook-Chill system and the Cook-Freeze system have been adopted by various food manufacturers and are in active use. Maybe you can also incorporate it in your business for better efficiency and productivity.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Freezing Neapolitan] rapid freezing demonstration](https://shunkashutou.com/wp-content/uploads/2016/09/napolitan.jpg)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[Introduced one after another in restaurants] Advantages of commercial rapid freezing! What about second hand ones?](https://shunkashutou.com/wp-content/uploads/2015/05/16920085ea8194572cc7c5babebedbe5_s.jpg)

![[Rapid defrosting or slow defrosting] Unsure of which method? Read the complete guide on how to defrost](https://shunkashutou.com/wp-content/uploads/2024/04/ec8d0eb82bcecb5525574a8f72183a97.jpg)

![[Eliminating the labor shortage! ] Introducing the benefits of the cook-freeze system!](https://shunkashutou.com/wp-content/uploads/2018/12/95e9f56fecc5fd995cb205bd5b13596c_s.jpg)

![[Food/processing manufacturers] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_kakou_img_01.jpg)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2016/09/2a0deb9a6db53165f0a4938bc80cee46.jpg)

![[Manufacturing subsidies are recommended for rapid freezer! ] Explaining the ABCs of application](https://shunkashutou.com/wp-content/uploads/2020/12/4024568_s.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)