What is food yield? Explaining what is necessary to improve yield

Many people involved in food manufacturing and processing have probably heard of the term yield. Even if you know the term, there may be people who don't really know what it means, or how to improve it even if they say the yield is poor.

Yield is a term used not only in food products but also in industrial products and corporate recruitment activities. Especially in the case of food products, there is a relationship between the yield and the cost of materials, and if the yield is poor, there is a possibility that profits will decrease significantly.

Therefore, this site, which has been consulted by over 3,000 companies, will introduce in detail the yield of food products, and will also explain how to calculate and improve yield.

If you want to improve the yield of food products or want to know how to calculate yield, please read until the end and make use of it in your daily work.

目次

What is yield rate?

Yield, pronounced ``budomari,'' refers to the ratio of the amount of product actually obtained to the amount of production expected from the input amount of raw materials in general production such as food and industrial products. In the case of food, it can also be said to be the percentage of edible parts.

Generally, the higher the yield, the higher the quality of the raw materials and the better the manufacturing process.

Let's take a look at how to calculate yield and how to improve yield using beef as an example.

Until a cow becomes meat

Cattle are produced and shipped to producers. Once the meat is shipped, it goes through a number of processes before it is turned into meat and delivered to the table.

So how does meat become meat?

Cows are divided into carcasses and processed into meat.

There are two types of Wagyu beef farmers: breeding farmers and fattening farmers. Breeding farmers raise them for about eight months after they are born, and then they are shipped to the livestock market.

The cattle are auctioned at the livestock market, raised at fattening farms, and then shipped.

Raised cattle are shipped to slaughterhouses and meat centers via livestock markets.

Therefore, the skin, bones, and internal organs have been removed from the cow, and the bone-in condition, which is divided into two parts from the backbone, is called a carcass. Also, meat from which excess fat and bones have been removed is called cut meat.

The carcass weighs 400-600 kg and is over 2 meters long. On the other hand, partial meat is a carcass that is divided into 13 parts such as fillet, sirloin, and pork loin.

The portions are further processed and delivered as meat from retail stores to homes.

Yield is used to grade carcasses

I'm sure you've seen beef listed as A5 grade, A4 grade, etc. in places that sell beef.

Beef is graded, and the standards are determined by the Japan Meat Grading Association. This is aimed at promoting fair trade in carcasses at meat wholesale markets and meat centers, and is standardized nationwide.

Beef grading is determined by a combination of two types: ``yield grade'' and ``meat quality grade'', and there are 15 types in total. The higher the grade, the higher the price of beef.

■Yield grade

There are three yield grades: A, B, and C. B is the standard, higher grades are A, and lower grades are C. Bones, excess fat, etc. are removed from the carcass to make the meat part, and the more part meat that can be removed from the carcass, the higher the grade.

In addition, the four breeds of Japanese Black, Japanese Brown, Japanese Shorthorn, and Japanese Hornless breeds, as well as crossbred cattle between these four breeds, are subject to additions.

■Flesh quality grade

There are five meat quality grades: 5, 4, 3, 2, and 1, and the grades are based on the quality of the beef. 3 is the standard, higher values are represented by 4 or 5, and lower values are represented by 2 or 1.

Meat quality grade is comprehensively determined from four items: fat crossbreeding, meat color, meat firmness and texture, and fat color and quality. Beef is graded and traded based on the yield grade and meat quality grade mentioned above.

Also, there is no tasting during the grading process, and judgments are made based on appearance. In other words, a large amount of beef can be obtained from one cow, and if the meat has good marbling, good color, and firmness, it will be evaluated better and given a grade such as A5 or A4.

Mainstream distribution is partial meat

As you probably know, meat goes through a number of processes before becoming meat, and now more and more meat is being distributed as cut meat.

The reason for this is that transportation costs are lower when transporting partial meat rather than carcasses.Since bones and excess fat are removed from partial meat, transportation costs are reduced by about 30 to 40% compared to carcass. It is said that

Portion meat is often vacuum packaged, which is superior in terms of maintaining freshness, and also from the viewpoint of increasing trade by meat part and improving work costs and productivity through processing at the production area. It is expected that the distribution of meat will continue to increase.

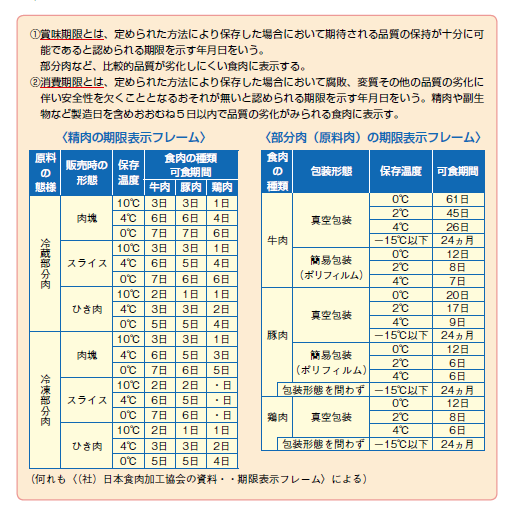

Considering the above points, you might think that it would be more efficient to process parts of meat into meat at the production area, but processing it into meat would shorten the edible period of the meat. .

Source: http://ajmic.or.jp/kumiai/2010pdf/p39-41.pdf

In this way, vacuum-packaged beef parts have a shelf life of about two months at a storage temperature of 0°C, but when processed into meat, they last only 7 days at 0°C.

Therefore, it is important to process only the necessary amount of meat from parts to meat. When processing partial meat into meat, inedible parts such as fat and scraps are produced, and yields vary depending on the processing method and the condition of the meat.

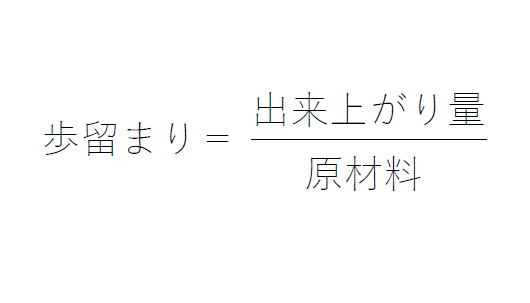

How to calculate yield

How should I calculate the yield during processing?

Let's take a look at the yield rate when cutting chunks of sirloin for steak.

Let's say there is a 10 kg piece of sirloin from one cow. When this sirloin was processed into steak, 40 pieces of meat each weighing 200g were made. What is the yield at this time?

How to calculate food yield

Edible portion ÷ total weight

It can be shown as

Applying this formula to sirloin

The edible portion is 200g x 40 = 8000g (8kg), so

8(kg)÷10(kg)=0.8

It becomes.

Higher yields not only increase the amount of meat that can be processed, but also lead to higher profit margins. So what can we do to improve yield?

To improve the yield of parts and meat

Source: http://dokkoisyo.jp/work/1605/

There are several ways to improve yield during meat processing, but here we will introduce two methods.

The first is to stabilize the storage conditions of the meat.

Meat discolors over time, so during processing there is a process called trimming in which the discolored parts are cut off and excess fat is removed and shaped.

Preventing meat discoloration reduces the amount of trimming and increases yield during processing.

Meat stays in better condition when stored at a low temperature; if the temperature of the meat rises, it will deteriorate, so 0-2 degrees Celsius is preferable. It is also necessary to store the meat in vacuum packaging to prevent it from drying out and oxidizing due to exposure to air.

The second is to improve meat processing technology.

The amount of meat that can be extracted from a cut varies depending on the processor. Therefore, in order to improve the yield, it is necessary to process the material by skilled workers or by using machines.

How to improve frozen meat yield

Most domestically produced meat is distributed chilled, but about half of the beef imported from overseas is distributed frozen. Additionally, 70% of pork and almost 100% of chicken are imported frozen, and must be thawed before being used domestically.

The most common way to defrost meat is to defrost it in the refrigerator or in ice water, but some places also defrost it using a defrosting machine. If meat is not defrosted in a proper manner, drips are likely to occur, leading to lower yields.

If there is a temperature difference between the inside and outside of the food when it is thawed, the food will partially melt and the melted water will damage and rupture the cell membranes, causing drips to flow out.

In order to improve food yield, it is essential to prevent drips from flowing out, and to prevent drips from flowing out, it is important to eliminate the temperature difference between the inside and outside of the food during thawing. Some defrosting machines work inside the food to thaw it evenly, while others defrost it efficiently by defrosting it under high humidity.

In the case of meat, the yield can be improved by thawing it by eliminating the temperature difference between the inside and outside, and by processing it in a partially thawed state before completely thawing it.

Conclusion

What did you think.

Improving the yield not only increases the amount that can be distributed as a product, but also directly affects the price.

To achieve this, it is necessary to review manufacturing processes, improve food storage conditions, and devise thawing methods.

If you want to improve your yield by reviewing your food manufacturing processes and thawing methods, please consider this.

⇒⇒ [Evenly high quality] Advantages and types of commercial thawing machines

⇒⇒ [Storage period is greatly extended! 】Why should you vacuum freeze?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Explanation with photos! ] How to freeze beef, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/8717f2a867f52157bab47841b0f29019.jpg)

![[Thorough guide to preserving meat] Preservation methods, expiration dates, thawing methods, rapid freezing](https://shunkashutou.com/wp-content/uploads/2023/09/ec61889773cfed9c75aa97d9ca6c96dd-1.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Freshly made raw soba all over the country! ] Example of introducing a quick freezer at a soba restaurant](https://shunkashutou.com/wp-content/uploads/2016/01/6d8138adcf26c410c11b25d5b8d2f3de.jpg)

![[Which products are popular? ! ] Recommended frozen food ranking](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-ranking-1024x682-1.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2016/03/661ea3ee6264fab6520017622c656870.jpg)

![[Used in various fields] Points to note when purchasing liquid nitrogen](https://shunkashutou.com/wp-content/uploads/2015/06/864ed88d3bcf695fd1a9af88d772606c.jpg)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2016/09/2a0deb9a6db53165f0a4938bc80cee46.jpg)

![[Labor shortage]The benefits with examples of using rapid freezer](https://shunkashutou.com/wp-content/uploads/2019/04/hitodebusoku-article-main_pc.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Explanation of functions and issues] What is partial freezing, which slightly freezes food?](https://shunkashutou.com/wp-content/uploads/2017/04/ccae917b4f7af5ace617f93280a58247.jpg)

![[Many repeat customers! ] Increase sales by mail ordering our proud curry by rapid freezing!](https://shunkashutou.com/wp-content/uploads/2018/08/S__295895302-863x10241.jpg)

![[Eliminating the labor shortage! ] Introducing the benefits of the cook-freeze system!](https://shunkashutou.com/wp-content/uploads/2018/12/95e9f56fecc5fd995cb205bd5b13596c_s.jpg)