[A must-see for restaurants that serve rice] What is rapid freezing that can preserve rice for a long time?

There are many restaurants that sell rice, such as bento shops, sushi shops, Japanese restaurants, Chinese restaurants, onigiri specialty shops, etc.

The problems faced by such businesses are as follows:

“I want to freeze rice menus to improve work efficiency.”

"I have a lot of rice left over, but I don't want to throw it away."

“I want to expand the sales channels for menu items that use rice such as sushi!”

I often hear stories like this.

Therefore, this time we will introduce `` rapid freezing'' that solves these problems.

What impression do you have of ``freezing''?

Currently, many people have a negative impression of "quality deterioration." In fact, by rapid freezing the rice, it is possible to keep it in a high-quality state that can be served to customers after thawing.

Also, even if you say rice in bulk, it can be used for a variety of purposes, such as white rice, cooked rice, sushi rice, and rice balls.

This time, we will explain in detail for businesses that handle rice, from the benefits of rapid freezing to the profits that can be expected by introducing rapid freezing.

目次

Why is the shelf life of rice so short?

As you know, rice deteriorates over time from its freshly cooked state. Depending on the temperature and quality, it can be stored at room temperature for about 12 hours, and refrigerated for up to 3 days.

Even though it can be stored, it does not mean that it can be stored while maintaining the freshly cooked quality. (Packed rice can be stored for long periods of time by maintaining strict sterile conditions, but this is difficult unless you are a company specializing in this.)

So why does rice have a short shelf life?

Because rice contains large amounts of moisture, starch, and sugar, which are favorite foods for bacteria, it is susceptible to spoilage and deteriorates over time after it is freshly cooked.

Refrigerated storage suppresses the growth of bacteria, but the starch contained in rice tends to age particularly in the refrigerator temperature range, resulting in rice becoming dry.

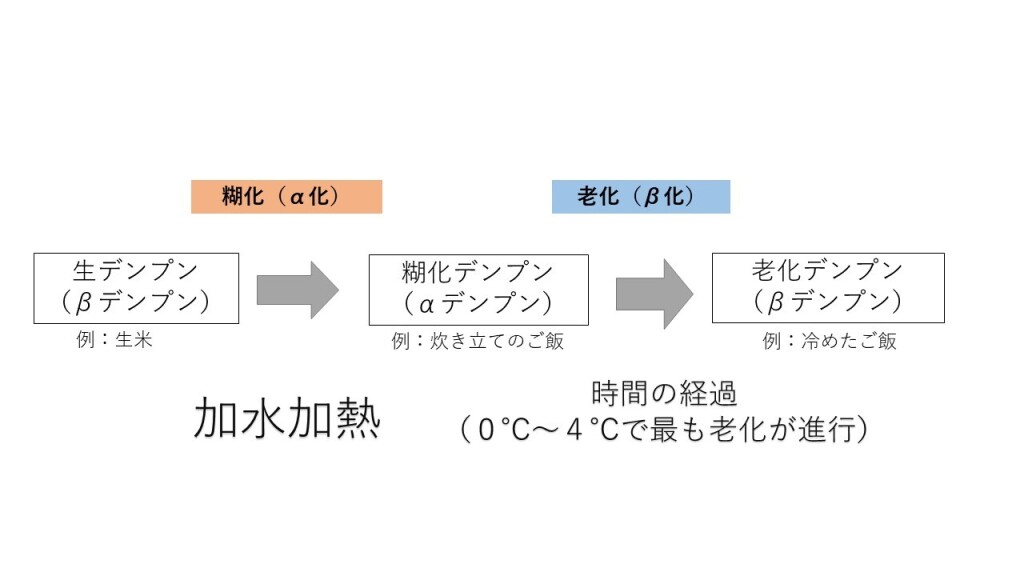

(Starch aging: When water is added and heated, starch absorbs moisture and becomes soft, which is called gelatinization. After that, when the temperature of the starch decreases, water separates from the tissue and it tries to return to raw starch, becoming hard. )

For this reason, ``freezing'' has been considered as a way to preserve rice deliciously.

Concerns faced by businesses that handle food

You may be experiencing the following problems due to not being able to preserve delicious food.

① Disposal loss and opportunity loss

I have leftover rice from what I prepared, but I can't save it so I throw it away.

An urgent order came in, but I couldn't fulfill it because I hadn't cooked the rice yet.

②Quality

Currently, rice is frozen and stored in advance, but the quality after thawing is low. Because it turns into white wax, it loses moisture and becomes dry.

We want to improve the quality of the food we provide to our customers.

③ Mail order is not possible

It is difficult to enter the mail order business as it is not possible to deliver the rice menu to customers while maintaining its quality.

④Responding to sudden orders increases personnel costs

If you suddenly receive a large number of orders for a menu item, you may have to decline the order because you cannot handle it, or you may need to increase your staff and continue manufacturing day and night. However, if manufacturing is carried out day and night, labor costs will increase.

Do you have these kinds of worries and issues?

Freezing experiment

What is the difference between rapid freezing and slow freezing (normal freezing)?

The biggest difference is that it prevents food quality from deteriorating.

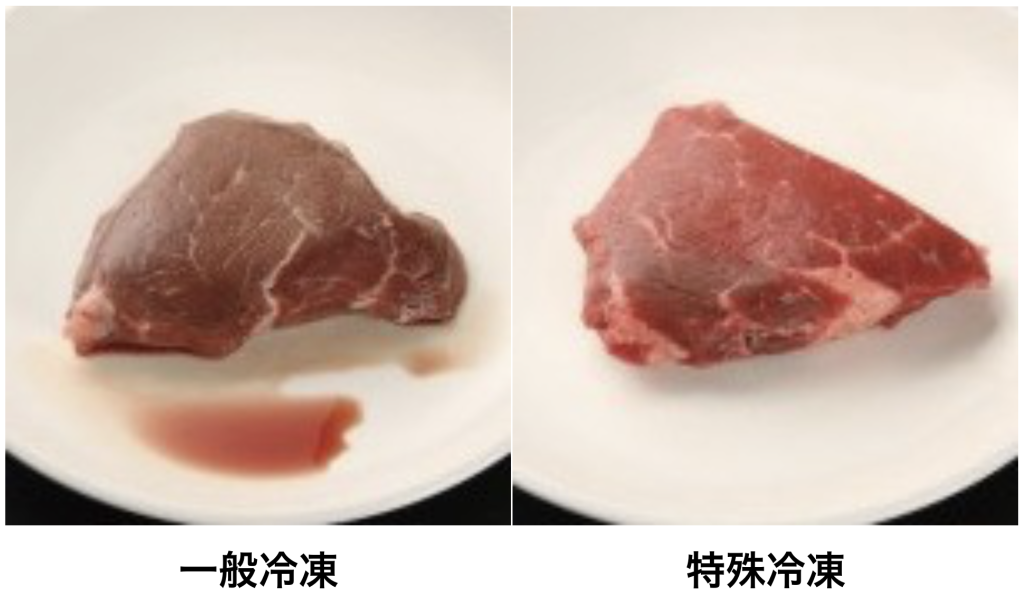

Conventional freezing methods (slow freezing) have had issues such as changes in texture and poor flavor. Food quality deterioration due to freezing is mainly caused by the leakage of flavor components and nutrients from cell membranes during thawing.

The reason why water and other substances leak out of food along with the umami flavor is caused by the crystals that form inside the food during freezing and destroy cell membranes.

The larger the crystal size, the more drips (moisture and flavor components) will flow out of the food. In other words, what determines the quality of food after freezing is the size of the crystals formed inside the food.

The temperature range where the water inside food turns into ice crystals is called the ``maximum ice crystal formation temperature range.'' When food slowly passes through this temperature range, the water expands more and the ice crystals that form inside the cells become larger. Reducing the size of crystals inside food is extremely important in maintaining food quality.

By rapid freezing reduces the size of intracellular crystals and prevents food quality from deteriorating.

Rice freezing experiment

This time I will introduce rice that was actually frozen using rapid freezer.

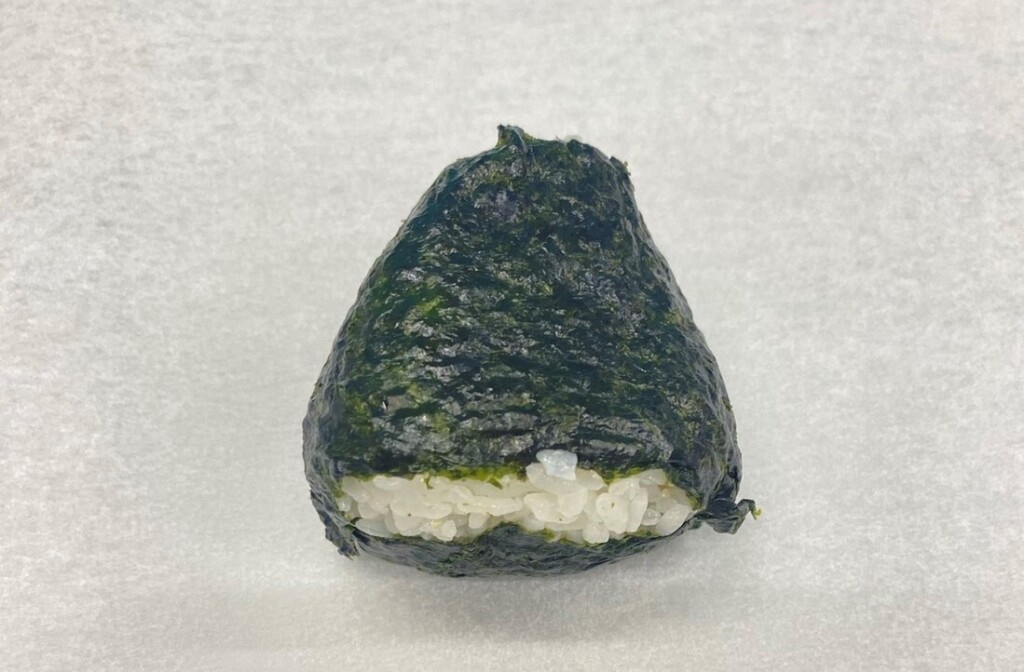

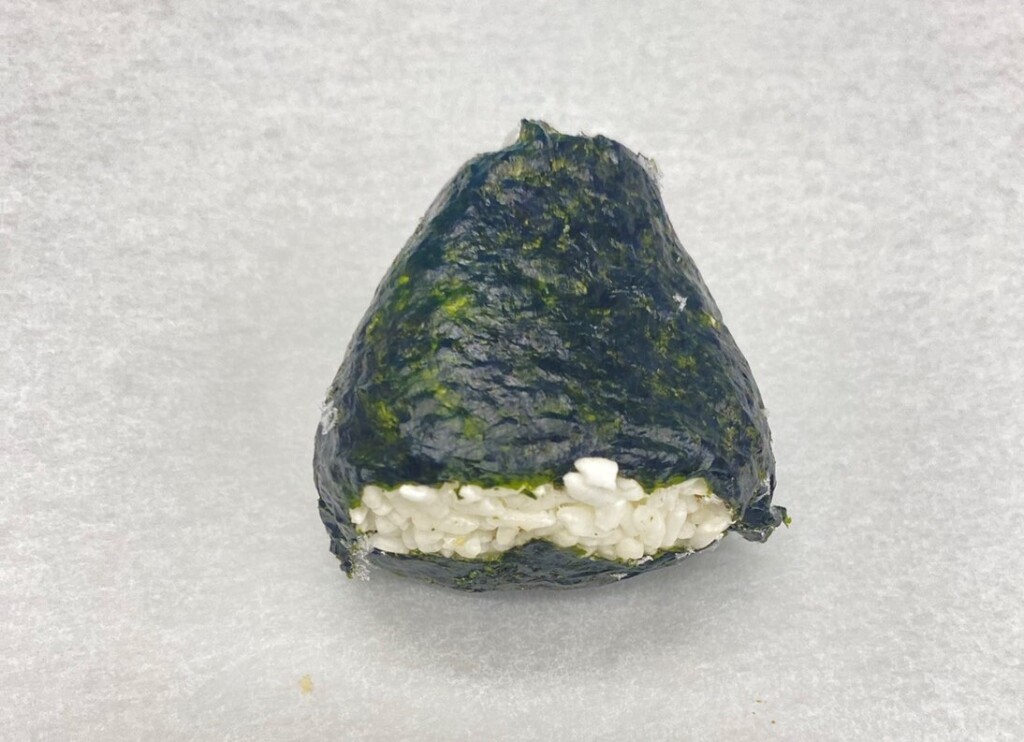

The first is rapid freezing of rice balls. (The freezing time and thawing method for rice balls vary depending on the ingredients.)

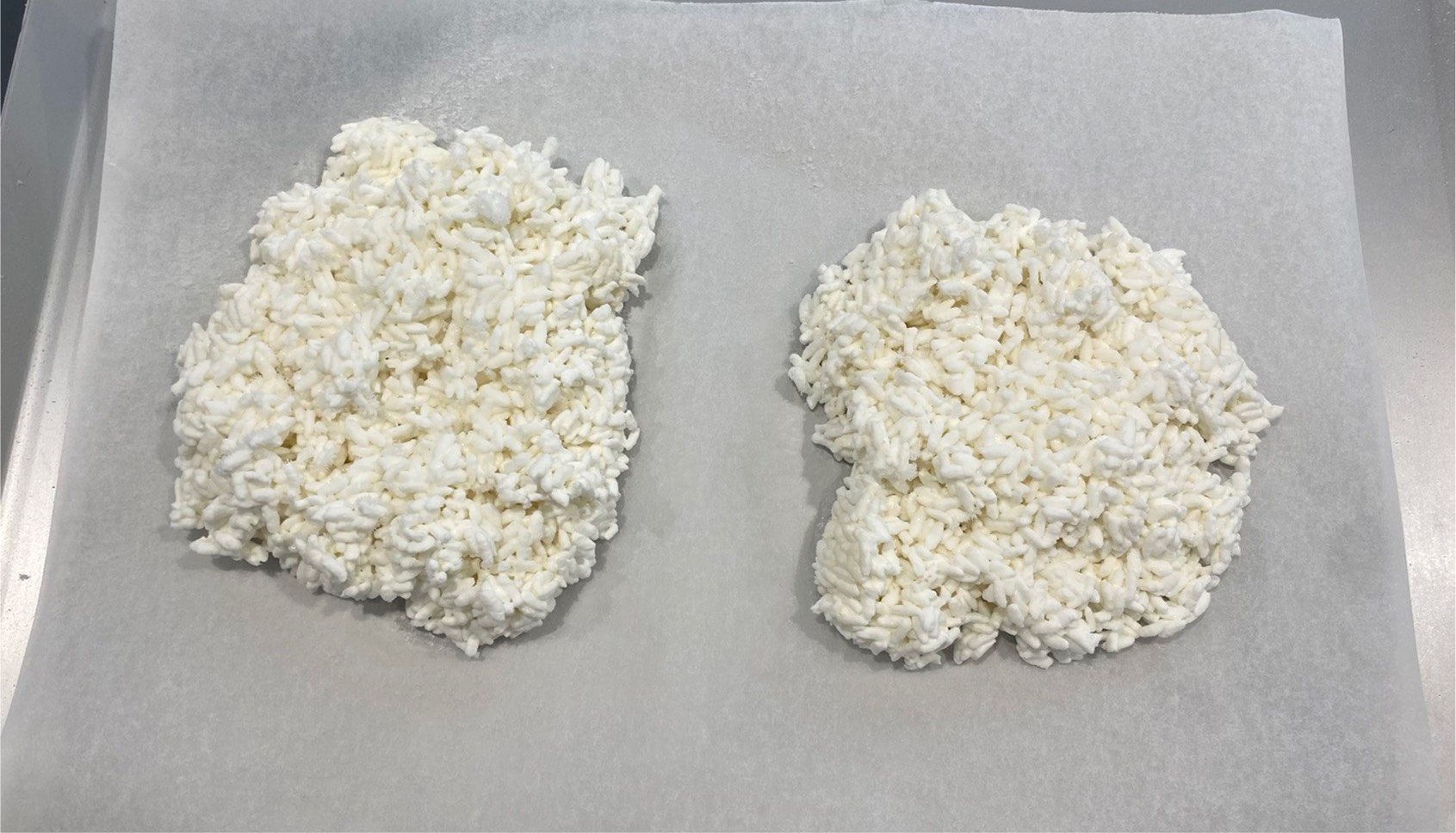

① Before rapid freezing

②After rapid freezing

③After thawing

Normally, when you freeze onigiri, the rice becomes waxy and falls apart, but if you look at these photos, you can see that the rice has not become waxy after thawing.

The texture was almost unchanged from before freezing.

When I slow-frozen (normally freeze) the same rice ball, when I cut it like in the third photo, the rice fell apart and fell apart.

The high quality of rapid freezing can be seen from this photo.

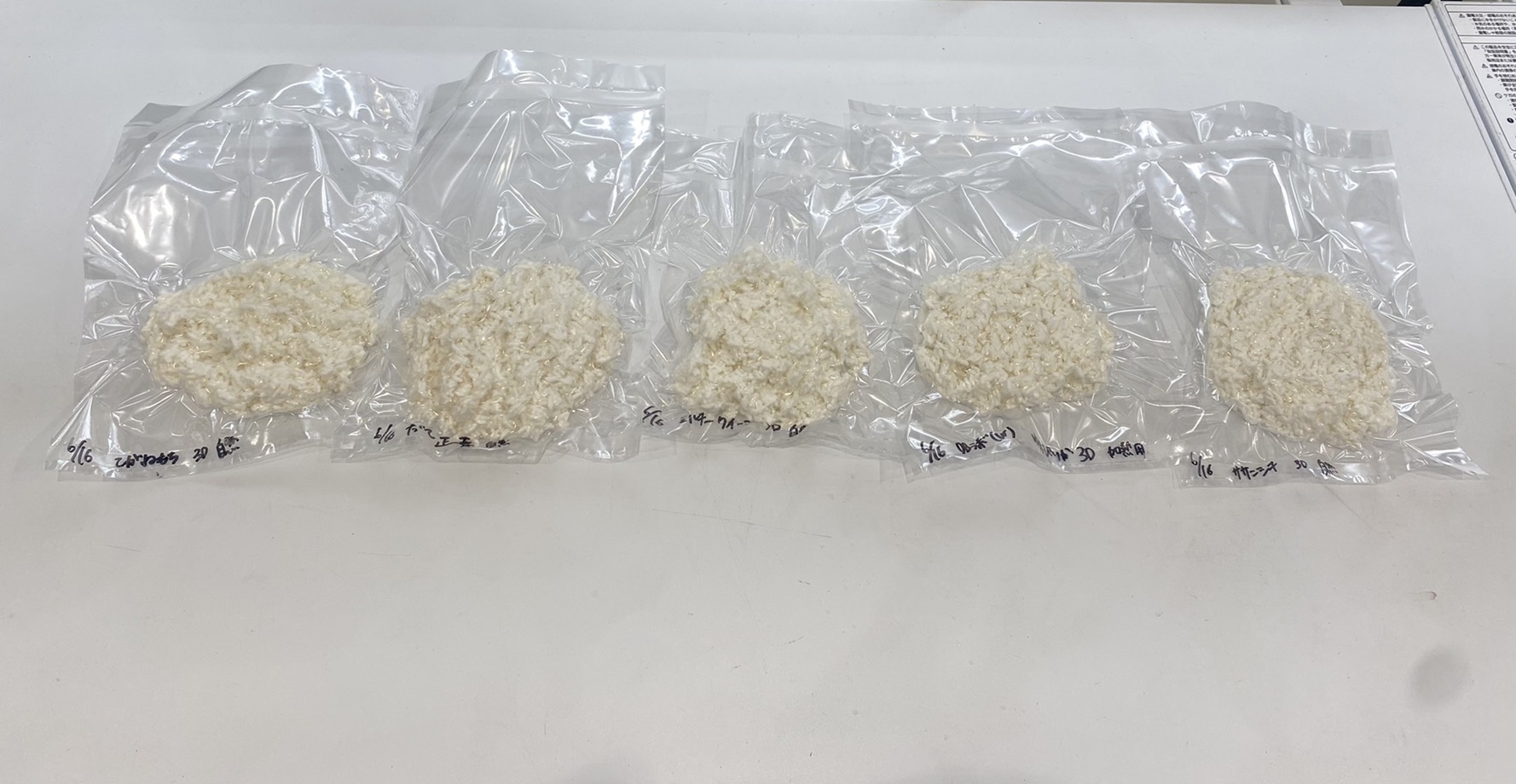

Next is freezing the rice.

<Freezing method> Art Lock Freezer

<Frozen ingredients> 5 rice items

<Temperature before freezing> 65.4℃

This time, we froze five varieties of rice and compared their quality after natural thawing.

<Before freezing>

<After freezing>

<After freezing ②>

Naturally thawed rice usually becomes dry, but rapid freezing rice retains moisture.

At our company, we are constantly researching the freezing, storage, and thawing of ingredients, and the compatibility of ingredients with each type of rapid freezer. We are also able to provide advice on food handling using the refrigeration know-how we have cultivated over many years, so please come visit our test room.

Achieving rapid freezing

By introducing rapid freezing, you can achieve the following:

Improve sales by expanding sales channels

Started selling through mail order and wholesale. By rapid freezing freshly made products, we can provide them with almost the same quality even after thawing.

Eliminating labor shortages

Planned production will become possible, and employees will be able to work in a stable manner throughout the year. Employee retention rates have increased, and we no longer have to worry about labor shortages.

Improving work efficiency

Refrigeration efficiency has been improved, making it possible to freeze faster than existing refrigeration equipment. In addition, since there is no need to defrost products, products can be frozen even during times when operations could not be performed, increasing production volume.

Eliminating food waste

rapid freezing allows you to preserve products that maintain their quality for a long period of time, making it possible to stock products. By always ensuring inventory, we prevent opportunity loss and also reduce waste loss.

In addition, by rapid freezing, it can be sold nationwide.

Improving food quality

Normal freezing methods often fail to reproduce satisfactory quality, such as leakage of flavor components and discoloration. rapid freezing enables long-term storage and adds value to products.

In addition, rapid freezing of fresh fish can prevent loss of freshness. Some research has shown that frozen foods have more nutrients.

4 tips to solve your problems with rapid freezing

By using rapid freezing, the concerns faced by business operators as mentioned earlier can be resolved from the perspectives of "improving business efficiency" and "improving sales."

Business efficiency

①Reducing waste loss and opportunity loss

I have leftover rice from what I prepared, but I can't save it so I throw it away. An urgent order came in, but I couldn't fulfill it because I hadn't cooked the rice yet.

[After introduction]

By introducing rapid freezer, it is possible to preserve high quality food and reduce waste loss. Furthermore, by having sufficient stock, we can now respond to sudden orders and eliminate opportunity losses.

②Quality

Currently, rice is frozen and stored in advance, but the quality after thawing is low. Because it turns into white wax, it loses moisture and becomes dry. We want to improve the quality of the food we provide to our customers.

[After introduction]

rapid freezing makes it possible to provide high-quality rice that retains moisture without becoming waxy. Freezing time is also significantly shortened, allowing you to free up your time for other tasks.

Sales improvement

③ Mail order is not possible

It is difficult to enter the mail order business as it is not possible to deliver products to customers while maintaining their quality.

[After introduction]

Because we are able to produce high-quality products, we are now able to deliver products to customers far away by mail order. This is expected to improve sales.

④Responding to sudden orders increases personnel costs

If you suddenly receive an order for a large quantity of products, do you have to decline the order because you can't handle it, or do you hire more staff and manufacture it day and night? However, labor costs increase when manufacturing is performed day and night.

[After introduction]

By preparing the items in advance during free time, there is no need to hire more part-time workers, and you can expect a significant reduction in labor costs. Long working hours such as night shifts will be eliminated, the working environment will be improved, and the employee retention rate will increase.

So, how much can you actually increase profits by introducing rapid freezing?

Here's a concrete example of how to increase sales.

・Employees: 4 people

The shop is quite busy during the morning preparation time and lunchtime, but after lunchtime, there is free time.

With the introduction of rapid freezer...it became possible to prepare lunch boxes for the next day during free time after lunch time.

Thereby…

→Reduced morning preparation time

→You can use the free time after lunch time to prepare for the next day.

→As a result, you can reduce your morning preparation time by 1 hour! (Reduced burden by working from early morning → Improved working environment)

Reduce working hours by 1 hour per day

Hourly wage 1,000 yen x 1 hour x 4 people x 25 days per month x 12 months

In other words Possible to reduce labor costs by 1.2 million yen per year It will be.

This is just an example, but introducing rapid freezing has the potential to significantly reduce labor costs. In addition, reducing food waste increases profit margins and greatly contributes to increased sales.

What is the best machine for rapid freezing rice?

When our company installs a machine for the purpose of rapid freezing rice, many of our customers choose the ``Artlock Freezer.''

Features of Art Lock Freezer

・Micro window system

Equipped with a micro-wind system, it suppresses damage to food (drying, cracking, oxidation, etc.) that occurs during freezing, and enables high-quality freezing.

By creating a well-balanced flow of fine air inside the refrigerator, uniform quality can be maintained without uneven freezing.

In addition, because it has a strong ability to remove heat, freezing time can be significantly shortened compared to regular rapid freezer.

・Electronic control system (smart freeze)

In particular, when freezing hot items such as rice, the load on the freezer increases. Conventional mechanisms were unable to respond to load fluctuations, placing a strain on the machine.

Artlock freezers equipped with an electronic control system instantly adjust the valve opening according to load fluctuations. This reduces the burden on the machine and reduces the risk of failure.

In addition, since cooling can always be performed at optimal capacity, it also reduces electricity costs and increases the amount of refrigeration processed.

・No cooling required

Normally, if you want to rapid freezing freshly made, high-temperature products, you need to let them cool. While the food is cooling down, moisture from the food may escape into the air along with the steam.

You can't do any other work while it's cooling down...Artlock Freezer solves this problem!

Food can be put into rapid freezer while still hot, increasing production efficiency and preventing food from drying out.

In addition to the Artlock Freezer, many people are also installing rapid freezer called the ``Rejoice Freezer,'' which performs instant freezing using a liquid such as alcohol as a medium. This method is characterized by its fast freezing speed as it uses a liquid as a medium for freezing.

Which type of rapid freezer is best depends on each business's operations.

Click here if you would like to know more.

Customer implementation success stories

So far, we have introduced the benefits of rapid freezing rice and rapid freezer, but some people may not have imagined how it can actually be used.

Here, we will introduce the purpose of introducing rapid freezer, what kind of effects it produces, and some examples of actual successes in introducing rapid freezer.

sushi production factory

<Nationwide expansion becomes possible and sales increase>

【assignment】

Wanting more people to know about the deliciousness of their products, they conducted repeated research and trial and error to see if they could provide frozen products nationwide, but the quality was not consistent.

Before the introduction of the product, the products were frozen overnight in a prefabricated freezer (-35°C), but the quality was uneven and complaints often occurred during the summer.

[Effects after introduction]

The rice and ingredients for sushi no longer suffer from freezer burn (discoloration and wax formation), and the rice no longer hardens or dries out when thawed, allowing the quality of the product to be maintained.

Freezing stabilizes quality and standardizes manufacturing methods, making it easier to ascertain production times and purchase raw materials, making planned production possible.

Additionally, because everything was manufactured by hand, production was available 24 hours a day during peak seasons due to fluctuations in order volumes. The introduction of rapid freezing has made it possible to standardize and stabilize quality, and it has become possible to make production plans and maintain sufficient stock.

Previously, the product could only be sold chilled, but now it can be sold nationwide as frozen sushi, and sales are steadily increasing.

Conclusion

How was it?

By introducing rapid freezing, you can not only expect to increase sales by expanding sales channels and reducing labor costs, but also improve operational efficiency.

We introduced rapid freezing as the best way to preserve rice quality for a long period of time.

By reforming your business format using rapid freezing, you can make big profits.

Introducing rapid freezer can lead to various business opportunities, such as reducing rice waste and expanding sales channels.

Why not take this opportunity to consider installing rapid freezer?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[How long does it last? ] How to freeze cooked rice and how long it can be stored](https://shunkashutou.com/wp-content/uploads/2023/10/7e31499b015d58f220536e3274a41bf2.jpg)

![[Lunch boxes are easy! ] Techniques and recipes for effectively using frozen side dishes](https://shunkashutou.com/wp-content/uploads/2023/07/reitou-bento-1024x682-1.jpg)

![[Be good at saving money! ] Introducing the method and recipe for freezing fried rice](https://shunkashutou.com/wp-content/uploads/2023/10/mayo-tyahan-1024x768-1.jpg)

![[Recommended for those living alone! ] How to freeze rice, storage period, and easy recipes!](https://shunkashutou.com/wp-content/uploads/2023/08/b3c2c946949856ed2c8a8098eacf6641.jpg)

![[Many repeat customers! ] Increase sales by mail ordering our proud curry by rapid freezing!](https://shunkashutou.com/wp-content/uploads/2018/08/S__295895302-863x10241.jpg)

![[Should be frozen! ? ] How to freeze and thaw bread, 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/4691acc32cab80284fa0cddf72d58e95.jpg)

![[Must-see for bakers] 6 reasons why bakeries should use rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/02/f92a102c9d3cc8c63dc7e509ce6d35d2.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2016/03/661ea3ee6264fab6520017622c656870.jpg)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2016/06/09c17e4deeb1ac0cdc5a513eaf89ab1a.jpg)

![How to freeze bitter gourd and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/8fe0cb793c93d4fd4c26f352d17e5b87.jpg)

![[Introduced one after another in restaurants] Advantages of commercial rapid freezing! What about second hand ones?](https://shunkashutou.com/wp-content/uploads/2015/05/16920085ea8194572cc7c5babebedbe5_s.jpg)

![How to freeze rice balls, storage period, and arranged recipes [use leftover rice]](https://shunkashutou.com/wp-content/uploads/2023/10/2431752695ba1372808f3603c896a5d3.jpg)

![[Does alcohol freeze? ] Surprisingly unknown freezing temperature of alcohol and usage examples](https://shunkashutou.com/wp-content/uploads/2015/06/alcohol-630x420-1.jpg)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2016/03/99093c5fe8b0d716c39df907616e4a96.jpg)

![[Thorough Guide to Preserving Sweets] Introducing the freezing method, storage period, and thawing method in detail!](https://shunkashutou.com/wp-content/uploads/2023/10/bffcbc0b6e79bb1af6e05b930e11e949.jpg)