What is rapid freezing? Thorough explanation of everything from temperature and freezing time definitions to commercial use

rapid freezing is a freezing method that allows food to be frozen without reducing its quality and to maintain that state for a long period of time.

By cooling and freezing all at once, food cells can be frozen without being damaged as much as possible by freezing, and even after thawing, you can enjoy the taste and texture of the food before freezing.

This rapid freezing technology is used mainly for commercial purposes, not only by large companies but also by small and medium-sized businesses and individual restaurants.

Home-use freezers with rapid freezer are also sold by major manufacturers such as Mitsubishi Electric and Panasonic, but they are still weaker than commercial-use freezers, so they cannot demonstrate the true power of rapid freezing.

Our company, which is Japan's No. 1 rapid freezing specialist and has consulted with over 5,000 companies, will explain the technology of "rapid freezing" in detail, including examples of commercial rapid freezer are actually used. Let me introduce you.

Commercial rapid freezing is increasingly being used. Please watch till the end.

目次

Definition of rapid freezing (technology, temperature, principle)

Source: http://flash-freeze.net/ja/freeze-technology/freeze-slowly.html

“rapid freezing”, as the name suggests, refers to “quick freezing”.

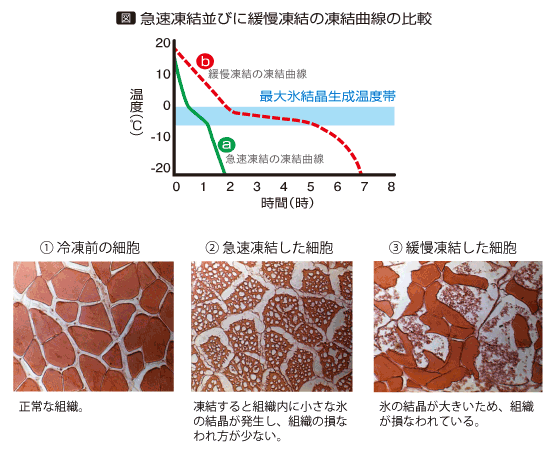

In terms of speed and time, by definition, food passes through the maximum ice crystal formation temperature range of -5℃ to -1℃, which is the temperature at which water in food turns into ice, within 30 minutes. It will be.

Normally, water expands when it turns into ice crystals, but in the process, the ice crystals break through the cell membrane of the food, causing flavor components and drippings to flow out from inside.

This is the biggest reason why ingredients and food don't taste good when thawed.

Therefore, during the freezing process, the key to maintaining quality is how to avoid destroying food cells and, ultimately, freezing the food without causing the ice crystals to enlarge.

In rapid freezing, by increasing the freezing speed to an ultra-high speed, it is possible to prevent the enlargement of ice crystals to the maximum extent possible and maintain the quality of the frozen product.

On the other hand, in conventional freezing (this is called slow freezing), the temperature range for maximum ice crystal formation is lowered over many hours, and during this time food cells are broken into pieces, resulting in loss of taste. is.

The summary is as follows.

Slow freezing slows down the freezing speed. Therefore, when the water, which makes up 70 to 80% of food, turns into ice, the volume expands and destroys cells.

Moisture and umami components flow out from the destroyed cells, resulting in poor texture and taste, and a decline in quality.

The freezing speed is fast and the water in the food can quickly pass through the freezing temperature range, which suppresses the growth of ice crystals and prevents cell destruction as much as possible.

Since it does not destroy food cells, it maintains freshness, flavor, and texture, and the taste and quality before freezing can be recreated upon thawing.

By using rapid freezing, food can be preserved for long periods without compromising its quality.

Because of this property, rapid freezing is widely used in commercial applications.

View the rapid freezing catalog in detail

Now, we will explain why this technology is so useful and what specific benefits and effects can be achieved by implementing it.

Benefits and effects unique to rapid freezing

In addition to the benefits of general rapid freezing, rapid freezing has many unique benefits.

This time, we will introduce five of the most important benefits and their effects.

production can be increased

Needless to say, the freezing speed is fast, so what used to take overnight to freeze will be completed in just a few minutes to an hour.

Since it can be frozen in a short time, the amount that can be frozen in the same amount of time can be doubled.

Since it is possible to increase production volume and reduce manpower accordingly, it also has the effect of improving production efficiency and reducing labor costs.

Can reproduce the taste of freshly made food

Source: https://toyokeizai.net/articles/-/120458

When is food the best?

Food that has cooled down over time is not tasty. After all, it's freshly made.

rapid freezing allows food to be frozen immediately after it is cooked, keeping it fresh and delicious.

Since the cells of the food are not destroyed, the surface of the food remains crispy even after being fried and thawed, allowing you to enjoy the crispy texture.

Since the food stays fresh for a long time, customers from far away can enjoy the taste of freshly made food.

No need to use additives

Source: https://sg.work/archives/615

rapid freezing allows food to be frozen without destroying its cells, and can be preserved for a long period of time, so over time, food may deteriorate in taste, change in color, lose its shape, etc. There is no such thing.

Therefore, additives such as preservatives, colorants, stabilizers, and preservatives are no longer required.

Since food can be maintained in a high quality state without relying on additives, it is possible to develop products that have health benefits. It can also compete as a recently trending health food.

Eliminate food waste

Being able to preserve food for long periods of time in good quality means that ingredients and food products are always available.

You no longer have to waste unused ingredients or food or dishes that have been overcooked, reducing food loss.

This also reduces disposal costs and purchasing costs.

No unevenness in quality

I'm mainly talking about freezers, but with slow-freezing freezers, the freezing time for each food item varies depending on how easily the cold air hits the inside, resulting in uneven quality.

Most rapid freezing freezers are equipped with a mechanism that freezes food evenly, so there is no uneven quality.

All foods can be frozen at once with uniform quality and deliciousness.

The above are the typical benefits and effects of rapid freezing.

In fact, for commercial use, many companies are taking advantage of these benefits to increase sales. There are many implementation examples, so if you are interested, please take a look.

See examples of rapid freezing implementation

Next, we will explain in detail what kinds of ingredients and foods are suitable for rapid freezing.

What foods are suitable for rapid freezing?

So, what kind of ingredients and foods are suitable for rapid freezing?

As mentioned above, ice crystals destroy food cells during the freezing process, so foods with a high moisture content are generally not suitable for freezing.

The same goes for rapid freezing, although the quality is better than slow freezing.

fresh fish and sashimi

Fresh fish and sashimi go very well with rapid freezing.

Some fish species with high oil content require special freezing techniques, but there is no problem if you think that almost all fish species can be frozen.

After thawing, it is possible to restore the quality to the same level as raw. With sashimi, you can restore the state where the corners are cut.

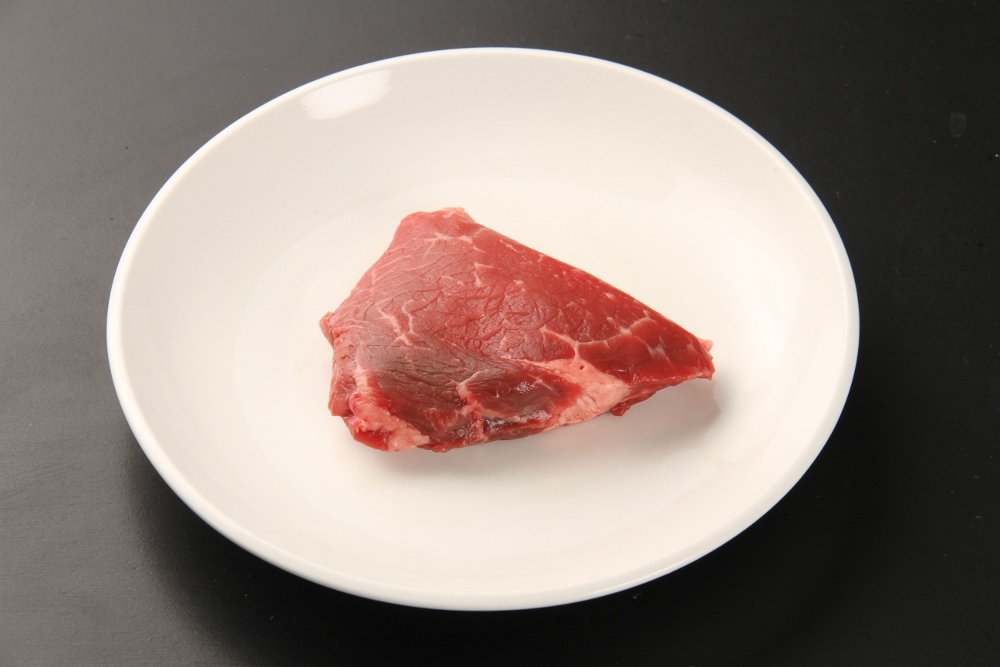

meat

It goes perfectly with meats such as beef, pork, chicken, and game. Almost all meats can be frozen.

You can choose the shape or size when rapid freezing.

There are almost no drips and the quality is high when thawed, so even a professional eye may not be able to tell the difference between raw meat and thawed meat.

fruits, vegetables

Fruits and vegetables are difficult to freeze even with quick freezing, as well as rapid freezing.

Because it has a high water content, it will become soft after thawing and a lot of drips will come out.

However, the quality of frozen food is much better than slow freezing, so there is a way to use it as a raw material while frozen.

Rice, bread, side dishes, bento boxes, etc.

Think rapid freezing is only suitable for fresh ingredients?

In fact, rapid freezing is very compatible with cooked foods and processed foods.

From side dishes such as rice, bread, and fried foods to bento boxes, you can keep them hot and fresh.

Therefore, in recent years, its use in food manufacturing industries, restaurants, caterers, etc. has rapidly increased.

Next, we will introduce rapid freezer for commercial use.

Introducing commercial rapid freezer and what are their characteristics?

We have introduced the various benefits of rapid freezing and the ingredients and foods that go well with it, but we would like to introduce the types of commercial rapid freezer that can achieve these benefits.

air blast refrigerator

It blows cold air like a normal freezer, but it freezes with strong cold air of -30℃ to -45℃.

There are many air blast type rapid freezer on the market, the most famous of which are shock freezers and blast chillers.

A blast chiller refers to a machine that cools hot food to the chilled temperature range, and a shock freezer refers to a machine that cools food from the chilled temperature range to below -18℃.

Among the air blast type rapid freezer, there is rapid freezer with good performance called Artlock Freezer. This machine is great because it allows you to freeze freshly cooked food while still hot.

Artlock Freezer differs from general shock freezers in that it is equipped with a micro-wind system and an electronically controlled refrigeration system.

This increases heat transfer efficiency and achieves high-quality freezing by freezing at a faster speed.

It automatically adjusts to the optimal setting according to changes in the temperature and humidity of the outside air and the temperature of the objects being added, making it possible to freeze not only chilled foods but also piping hot, freshly cooked foods.

View the Artlock Freezer catalog

liquid quick freeze machine

Re-Joice Freezer is a liquid-type (liquid freezing) rapid freezer that freezes food by immersing it directly in a bath of alcohol.

The thermal conductivity of liquid is about 20 times higher than that of air, so it cools down quickly and freezes faster than a cold air rapid freezer.

It makes ice crystals as fine as possible and prevents the destruction of food cells, which causes drips, to the utmost. It is mainly used for rapid freezing of perishable products.

View the Rejoice Freezer catalog

liquid nitrogen refrigerator

Liquid nitrogen at -196°C is sprayed directly onto food to freeze it.

Liquid nitrogen at -196°C has a high cooling capacity, so it can be frozen efficiently and quickly.

However, it requires care in handling and storage, so it is mainly used in food processing plants that freeze large quantities of food.

Conclusion

As mentioned above, I hope you understand that rapid freezing has various benefits and effects, and that installing a commercial rapid freezer can be very useful.

As rapid freezing is increasingly being used in the food freezing field, if food manufacturers do not have the option of rapid freezing, they will be left behind in the future competition for survival.

In fact, many companies are increasing sales through rapid freezing. Our company has a cumulative track record of consulting with more than 5,000 companies and has the No. 1 implementation track record in Japan, so we can introduce many case studies.

If you are interested, please contact us.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Delicious frozen squid recipe! ] Tips on how to eat squid deliciously and without waste](https://shunkashutou.com/wp-content/uploads/2023/10/f3bc339b6bcaff01bd8e2aaa4257acfe.jpg)

![[Various recipes] 3 tips for using frozen minced meat deliciously](https://shunkashutou.com/wp-content/uploads/2023/08/e9b2fc255393916ab79ea8b7fa0807d3.jpg)

![[Can it be frozen? ] How to freeze bacon, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/52dff5bc109cd400879fbf9bb35b3856.jpg)

![Introducing how to freeze fried chicken and a delicious recipe [Explaining tricks and techniques]](https://shunkashutou.com/wp-content/uploads/2023/09/2d15a108b8d7de5b4811f69c9bc8b8f1.jpg)

![[How long does frozen fish and meat last? ] Interesting expiration dates and tips to extend the shelf life](https://shunkashutou.com/wp-content/uploads/2023/08/f124221382987fe32d0ffda6b6f497c1.jpg)

![[Easy thawing method] Low temperature thawing to lock in the deliciousness of meat](https://shunkashutou.com/wp-content/uploads/2015/06/899e71a518bbd73569bf085ff0accd61.jpg)

![[Deliver delicious ham! ] Meat processing manufacturer’s rapid freezing implementation example](https://shunkashutou.com/wp-content/uploads/2016/02/0825c4a97ac8495fd2408a91574cede6.jpg)

![[A must-see for restaurants that serve rice] What is rapid freezing that can preserve rice for a long time?](https://shunkashutou.com/wp-content/uploads/2021/02/rice.jpg)

![How to freeze rice balls, storage period, and arranged recipes [use leftover rice]](https://shunkashutou.com/wp-content/uploads/2023/10/2431752695ba1372808f3603c896a5d3.jpg)

![[Be good at saving money! ] Introducing the method and recipe for freezing fried rice](https://shunkashutou.com/wp-content/uploads/2023/10/mayo-tyahan-1024x768-1.jpg)

![[Must-see for bakers] 6 reasons why bakeries should use rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/02/f92a102c9d3cc8c63dc7e509ce6d35d2.jpg)

![[Should be frozen! ? ] How to freeze and thaw bread, 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/4691acc32cab80284fa0cddf72d58e95.jpg)

![[Is it more nutritious than raw? ] Introducing recipes and how to preserve frozen blueberries](https://shunkashutou.com/wp-content/uploads/2023/07/bdc074d8bfa2dc63c2c7bf92dc1dd07d.jpg)

![[Explanation with photos] How to freeze peaches, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/b454a38d482a64b14d55d2560aa4193a.jpg)

![Freezing fruits (melons, grapes, pineapples) [rapid freezing demo]](https://shunkashutou.com/wp-content/uploads/2017/04/f6c25534c570755c38676fba88215298.webp)

![[Wholesale] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_oroshi_img_01.jpg)

![[Can it be frozen?] Stew freezing method, storage period, and arrangement recipe](https://shunkashutou.com/wp-content/uploads/2023/10/f599b814ea21eef57604e4ceb2518d5b-1.jpg)

![[Current situation and countermeasures for food loss] What are efforts to reduce food waste and rapid freezing? ?](https://shunkashutou.com/wp-content/uploads/2024/04/ddc2c5b7fa32b837dcbdcd1ab68e9087.jpg)

![[Explanation with photos! ] Shiitake mushroom freezing method and storage period, 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/shiitake-768x512-1.jpg)

![How to freeze potatoes and a great time-saving recipe! [Moms must see! ]](https://shunkashutou.com/wp-content/uploads/2023/10/potato1-768x512-1.jpg)

![[Secret Technique] Introducing the freezing preservation and remake recipe of Kinpira Burdock!](https://shunkashutou.com/wp-content/uploads/2023/09/4c4b704274331befeed83cc4493acb75-1.jpg)

![How to freeze rice cake, expiry date, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/bd019f04ad570f697ffefe9ffd2e1e71.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2016/03/661ea3ee6264fab6520017622c656870.jpg)

![[Solving freezing problems] Performance and price of Re-Joice Freezer](https://shunkashutou.com/wp-content/uploads/2015/06/c808eaf7291922d0d2620606010122fe.jpg)

![[Required for food business operators] What is the reason for implementing HACCP and using rapid freezing?](https://shunkashutou.com/wp-content/uploads/2017/02/b9dcd4b8ff706013bae4aafeda989b6e.jpg)

![[Advantages and disadvantages of food additives] What is rapid freezer that solves the problems?](https://shunkashutou.com/wp-content/uploads/2018/11/ea1a552f8cb49685b3566dc4f06cf04b.webp)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2016/09/2a0deb9a6db53165f0a4938bc80cee46.jpg)

![Shock freezer prices and reasons why we can't recommend used ones [What's the difference from a blast chiller? ]](https://shunkashutou.com/wp-content/uploads/2019/09/f76c6907f41d0b092e20d0924e5f27c9.webp)

![[Explanation with photos! ] How to freeze mackerel fillets and 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/bf45f102162a8d43387d3a8d3e538034.jpg)

![[8 times more nutrition! ] Introducing how to freeze clams, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/57204e2a2f115f810e29e365cfc86638.jpg)

![[For vegetable processors] What is the blanching process that improves the quality of frozen vegetables?](https://shunkashutou.com/wp-content/uploads/2016/09/ad38a1a4c704bc39303ac1864f5b0b8d.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2016/03/99093c5fe8b0d716c39df907616e4a96.jpg)

![[Thorough guide to preserving meat] Preservation methods, expiration dates, thawing methods, rapid freezing](https://shunkashutou.com/wp-content/uploads/2023/09/ec61889773cfed9c75aa97d9ca6c96dd-1.jpg)

![How to freeze grapes, thaw them, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/c773e4ee54900a04329b03d0df5c7834.jpg)

![[Freezing dried persimmons] rapid freezing demonstration](https://shunkashutou.com/wp-content/uploads/2017/01/cc45cd14917f372d2e7aa6a5eeda4583.webp)

![[Achieving low cost and high quality] The problems of pubs can be solved with a quick freezer!](https://shunkashutou.com/wp-content/uploads/2016/02/11d55612344a4cbad2ad506ae700c81b.jpg)

![[Delicious, Convenient, Cheap] Recommended commercial frozen foods for restaurants to purchase](https://shunkashutou.com/wp-content/uploads/2023/07/business-frozen-food-1024x682-1.jpg)

![[Explanation with photos! ] How to freeze green beans, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/f3dbbe5b1d05a50f514a833efdceced9.jpg)

![[Can it be frozen? ] How to freeze fresh cream, storage period, thawing method and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/1887f5bd8f2d7f9ef1d88754f2c5bcc4.jpg)

![[Fruit becomes dessert! ] How to freeze kiwi and sweets recipes](https://shunkashutou.com/wp-content/uploads/2023/09/ecc0fc2bc14391ea13ce2e7a43d1416e.jpg)

![[Which products are popular? ! ] Recommended frozen food ranking](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-ranking-1024x682-1.jpg)

![[Thorough explanation! ] What is the distribution and cold chain that maintains the quality of frozen foods?](https://shunkashutou.com/wp-content/uploads/2016/11/ed15366b2a889239b39608c181587427.jpg)

![How to freeze bitter gourd and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/8fe0cb793c93d4fd4c26f352d17e5b87.jpg)