Types of rapid freezer and purchasing points! [Examples of failures in machine selection! ? ]

rapid freezing technology allows food to be frozen without sacrificing quality, and rapid freezer is required to utilize this technology.

What kind of rapid freezer are there, and what criteria should I use when purchasing one?

There are many different types of machines that can be grouped together as rapid freezer. Each machine has different features and prices, so you may be confused as to which one to buy.

Each machine has its own usability and compatibility with food, so when choosing a machine, you cannot make a decision based on price alone.

However, purchasing rapid freezer is not a cheap purchase, so you definitely don't want to make a mistake when choosing a machine.

Therefore, this website, which is the only trading company specializing in rapid freezer in Japan and has a track record of consulting with over 5,000 companies, will explain the key points when choosing rapid freezer, based on examples of failures.

Please read until the end and choose a machine you won't regret.

目次

What is rapid freezer? Introducing 3 types!

The definition of rapid freezing is ``the freezing of food by passing through the temperature range of -5℃ to -1℃ within 30 minutes.''

Therefore, the machine that enables this rapid freezing is called rapid freezer. There are other names such as rapid freezer, quick freezers, flash freezers, etc., but here we will explain them as rapid freezer.

There are three main types rapid freezer. There are three types: air blast refrigerators, liquid rapid freezer, and liquid nitrogen refrigerators.

Artlock Freezer is rapid freezer with good performance among air blast freezers. This machine allows you to freeze freshly prepared food without any cooling process.

In addition, since the food is frozen by blowing air around it, it is extremely unlikely to cause the unevenness that occurs in regular freezers.

The cold air that is applied to foods that tend to dry out is always kept in a high humidity state, so it can freeze food faster than other air blast freezers.

Liquids have approximately 20 times higher thermal conductivity than air and freeze at an incredibly fast rate. Since the liquid hits the food evenly, there is no uneven freezing.

This refrigeration principle minimizes the impact on the environment because it does not use chlorofluorocarbon gas.

However, there are disadvantages such as ``If the temperature is too low, cracks may appear in the food when freezing'', ``running costs increase significantly as a large amount of liquid nitrogen is used'', and ``liquid nitrogen is difficult to handle''. .

There are many different types of rapid freezer, but if you choose the wrong one, you may not get the desired effect, or you may end up using it for foods that are incompatible with it.

However, if you can choose the one that suits you best, rapid freezer is definitely a cost-effective option.

To avoid making mistakes when choosing a machine, let's take a look at past failures.

This is no good! ! Example of failure in choosing rapid freezer

rapid freezer are not cheap, so you can't go wrong when choosing a machine.

Therefore, we would like to introduce examples of past failures in choosing rapid freezer, so please use them as a reference for how to choose a machine.

However, the sashimi and rapid freezer I purchased were not compatible, and when I thawed it, it did not achieve the quality I was looking for. A regular customer always told him that the taste was different, so he stopped using that machine after that.

When we actually went to the manufacturer of rapid freezer and conducted a freezing test, we were very satisfied with the results, so we decided to install it.

However, when I visited the site a few months later, I found that rapid freezer was no longer in use. When I spoke to a staff member, I was told that using the rapid freezer increased the number of work steps, which actually made it less efficient and was no longer used.

In this way, it is not enough to simply install rapid freezer.

So what should I have done to avoid failure?

Therefore, we will tell you the key points when choosing rapid freezer to avoid any particular failures.

Points to consider when choosing rapid freezer!

There are four points to consider when choosing rapid freezer to avoid failure, which we will specially teach you this time. Please read until the end to avoid regretting your purchase.

Quality you want

The first thing you need to consider is how much quality you want to provide.

Even if you combine it with rapid freezer, its performance is outstanding. The difference in performance is clearly visible in the quality of thawed food. If the performance is poor, it will be difficult to maintain the same quality even after defrosting.

Also, the compatibility with food will change depending on rapid freezer. The machine you should buy will depend on what foods you want to rapid freezing.

You need to be clear about what you want to achieve by installing rapid freezer, such as if you want to produce in large quantities even if the quality is slightly degraded, or if you want to enjoy high quality and delicious food.

Cost-effectiveness

rapid freezer are not cheap. However, it is also true that the cheaper rapid freezer the lower the quality of defrosted food.

Some people buy based on price alone due to budget constraints, but many people use rapid freezer for more than 10 years. When purchasing rapid freezer, you also need to take a long-term perspective.

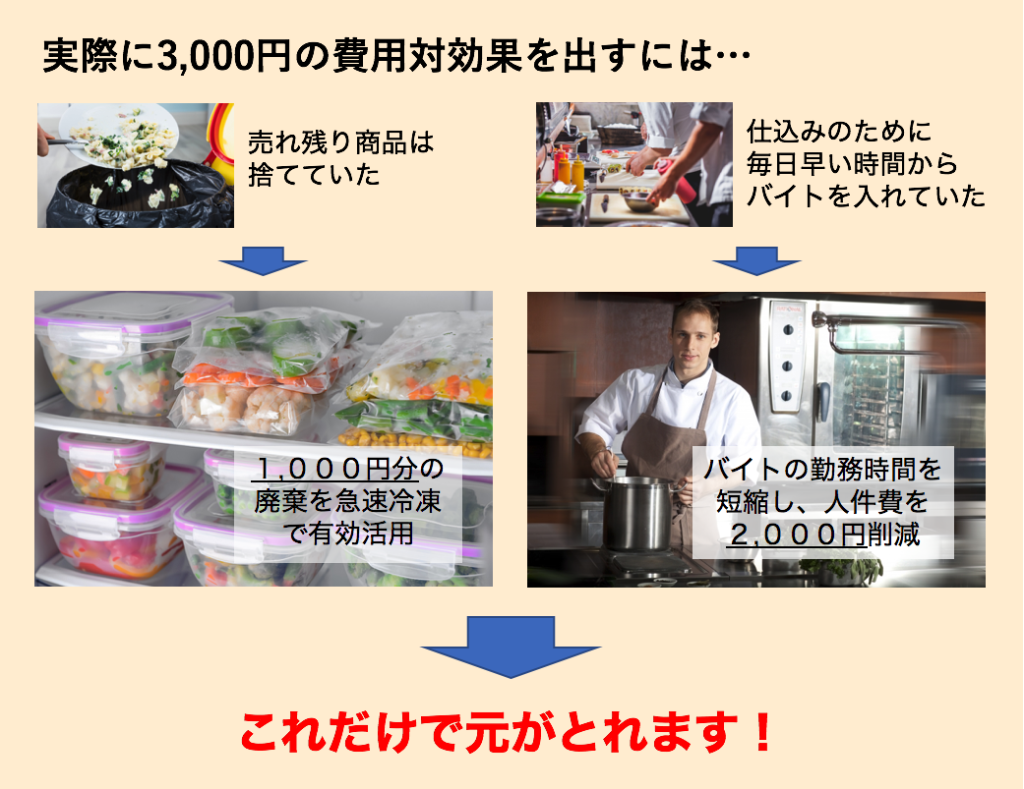

rapid freezer can be highly cost-effective in a variety of applications. The price of rapid freezer may seem expensive, but even if you purchase a high-performance rapid freezer and use it for five years, you will be able to get your money back if you can generate a cost-effectiveness of about 3,000 yen per day.

Keep cost-effectiveness in mind and choose rapid freezer from a long-term perspective.

Ease of use

Even if rapid freezer is said to be cost-effective, it is meaningless if it is not actually used. As in the example of processed meat product manufacturer R, the cost of rapid freezer cannot be recovered if they are not used.

Also, if it takes a lot of time to freeze, work efficiency will inevitably decrease. The amount of production that can be made is significantly different between something that can be moved only a few times a week and one that can be moved dozens of times a week.

In order to increase work efficiency on-site, a very important point of view is whether it is easy to use on-site. It is necessary to select a machine from the perspective of the site.

Aftercare

rapid freezer are machines that are used for a long period of time, over 10 years, and are not cheap. If there is no support when the rapid freezer breaks down, sales will be affected during the period when it cannot be used, and repair costs will only increase.

Any company that sells rapid freezer should be familiar with how to use them to their advantage. There is a big difference whether you know it or not.

It is also important to purchase from a company that provides good after-sales care, such as what to do in the event of a breakdown and tips on how to use the product.

Conclusion

How was it?

There are three types of rapid freezer enable rapid freezing without sacrificing quality: air blast freezers, liquid rapid freezer, and liquid nitrogen freezers.

When purchasing rapid freezer, it is important to note that not only the type but also the performance differs depending on the machine. It is also important to consider what level of quality you want after thawing, whether it is easy to use on site, and after-sales care such as what to do in the event of a breakdown.

rapid freezer provide high cost-effectiveness that far exceeds the price of the machine. It is necessary to select a machine from a long-term perspective, not only considering the price but also the performance that provides cost-effectiveness.

Please keep these points in mind and choose rapid freezer that you will not regret.

At our company, we are able to perform a freezing comparison test of rapid freezer, so if you are thinking of purchasing rapid freezer, please consider this. You can also download product materials for rapid freezer for free, so please take a look.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Solving freezing problems] Performance and price of Re-Joice Freezer](https://shunkashutou.com/wp-content/uploads/2015/06/c808eaf7291922d0d2620606010122fe.jpg)

![[Instant cooling at -196℃] What's up with cooling equipment that uses liquid nitrogen?](https://shunkashutou.com/wp-content/uploads/2015/07/4b219d54bd662f10cbae6ea211f612dd.jpg)

![[Achieving instant freezing at home] The evolving freezing function of home refrigerators](https://shunkashutou.com/wp-content/uploads/2015/10/93e403bcf18bda6b2d63c7c74fdef064.jpg)

![[Improve customer satisfaction] What can be solved by introducing rapid freezer at a lunch box delivery company for the elderly?](https://shunkashutou.com/wp-content/uploads/2016/08/dummy-related_02.jpg)

![[For maintaining food quality!] Three functions you should know about constant temperature and high humidity storage](https://shunkashutou.com/wp-content/uploads/2015/10/krefrigerator.jpg)

![[Which products are popular? ! ] Recommended frozen food ranking](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-ranking-1024x682-1.jpg)