What is air blast freezing? About advantages and disadvantages

Did you know that there are four main types of rapid freezer?

There are four types: air blast freezing, brine freezing, liquid nitrogen freezing, and contact freezing.

The foods that are suitable for freezing vary depending on the type of rapid freezer.

Please use this as a reference as we introduce how each type of rapid freezer works and its characteristics.

We also introduce the advantages and disadvantages of air blast refrigeration.

・What kind of freezing method is air blast?

・Are there any benefits to introducing air blast refrigeration?

・On the other hand, are there any disadvantages to air blasting?

We have received many questions like this, so we will explain them in this article.

目次

- 1What is rapid freezer? (Air blast, brine, liquid nitrogen, contact)

- 2 Advantages of air blast refrigeration

- 2.1Faster cooling possible than

- 2.2 Energy saving measures

- 2.3 Environment friendly

- 2.4 Does not require large installation space

- 3 Disadvantages of air blast refrigeration

- 4What is the recommended rapid freezer?

- 5Which factories are recommended for air blast refrigeration?

- 6Conclusion

What is rapid freezer? (Air blast, brine, liquid nitrogen, contact)

First of all, what is rapid freezer? I will answer the question.

rapid freezer is a machine used to rapidly freeze substances such as food and medicine. rapid freezer can suppress the growth of microorganisms and chemical changes by rapidly cooling substances in a short period of time.

This feature helps maintain the quality and extend the shelf life of food and pharmaceutical products.

About types of rapid freezer

When choosing rapid freezer, first understand the types of freezers so that you can smoothly decide which one to install.

There are four types of rapid freezer: air blast, brine, liquid nitrogen, and contact. I have summarized it below.

- air blast refrigeration

- brine frozen

- liquid nitrogen refrigeration

- contact refrigeration

air blast refrigeration

Air blast refrigeration is the most well-known method among refrigeration machines. Also called gas cooling type.

The mechanism is a method of cooling using air, as the word airblast suggests. By pressurizing the air and releasing the pressure, the temperature of the air can be rapidly lowered. Air blast refrigeration is now capable of more rapid cooling than previous cooling methods.

There are two types of air blasting methods: "batch type" and "tunnel freezer".

Batch type

In this method, trays or racks containing foods or medicines are placed in the freezer, the door of the freezer is closed, and chilled air is blown through to rapidly cool the food or medicines.

tunnel freezer

Food and medicine are placed on a conveyor belt inside a tunnel, and cooled air is applied to the items as they pass through the tunnel, so that they are frozen when they exit the tunnel.

Air blast refrigeration is mainly used for cooling foods, medicines, etc. Air blast refrigeration is currently attracting the most attention as an eco-friendly cooling technology because it is environmentally friendly and does not use refrigerants.

In addition, air blasting is a method of freezing food by blowing cooling air onto it, but applying strong wind can cause the product to lose its shape and dry out.

Therefore, there are high wind speed and low temperature air blast refrigerators and low wind speed and ultra low temperature air blast refrigerators.

The method of selection differs depending on the food to be cooled.

brine frozen

Brine freezing is also called "liquid cooling method."

Brine freezing is a method of cooling using liquid. Liquids can be rapidly cooled using salted water and alcohol.

Salt water has a freezing point of approximately -6°C, which is lower than water, so it can be cooled quickly at lower temperatures.

liquid nitrogen refrigeration

Liquid nitrogen freezing is a method of rapid cooling using liquid nitrogen. The temperature of liquid nitrogen is approximately -196℃, and ultra-low temperature cold air can be applied to materials.

The advantage is that food can be frozen rapidly, which reduces tissue damage.

However, this freezing method tends to be expensive to run, so it is often used in high-end restaurants.

contact refrigeration

Contact refrigeration, also known as `` plate refrigeration,'' is a method of cooling by sandwiching metal plates. Food can be cooled by flowing cooling material at about -40℃ to -30℃ inside the metal plate and sandwiching the food.

Contact freezing is a cooling method often used for minced fish and paste products.

Advantages of air blast refrigeration

Introducing the benefits of air blast freezing.

The four main benefits of air blast refrigeration are as follows.

- Allows for faster cooling

- Energy saving measures

- Environmentally Friendly

- Does not require large installation space

Allows for faster cooling

Airblast uses a high velocity stream of cold air to provide cooling. This allows the product to be cooled while preserving its freshness and flavor without degrading its quality.

Energy saving measures

Airblast utilizes air for cooling, so compared to older coolers, it can use less electricity to cool things down.

Environmentally Friendly

Air blast refrigerators are very environmentally friendly as they do not use refrigerants.

It also helps reduce carbon dioxide emissions.

Does not require large installation space

Air blast refrigerators are more compact than conventional refrigerators. Since it does not require a large amount of space within the factory, the empty space can be used as another space. There are also mobile air blasters that are equipped with casters depending on the manufacturer. It is a good idea to choose one according to the size and purpose of your factory.

Disadvantages of air blast freezing

Next, we will introduce the disadvantages of air blast freezing.

The two main disadvantages of air blast freezing are ``drying effect'' and ``uneven cooling.''

drying effect

Since air blasting uses air to cool the product, moisture can easily evaporate on the surface of the product, potentially drying it out. Drying causes deterioration of quality and changes in flavor. We recommend that you do not use air blasting if drying food or medicine would be a problem.

Uneven cooling

The cooling time may vary depending on the way the wind blows in the factory, resulting in uneven cooling of the product.

Therefore, it is important to carefully read the machine's manual and place the product correctly before installing it.

In response to these issues, some manufacturers have introduced air blast refrigerators that improve uneven cooling by applying cold air to the food in a way that wraps it around the food from multiple directions.

What is the recommended rapid freezer?

So far, we have introduced "rapid freezing?" and "Advantages and disadvantages of air blast freezers," but below we have summarized the recommended rapid freezer.

Re-Joice Freezer (liquid freezer)

This type freezes food by placing it in a bath of alcoholic liquid cooled to -35℃.

merit

- Amazing freezing speed

- Can be frozen all at once without unevenness

When I tested the freezing speed with konnyaku jelly, I found that

Place it in the "Re-Joice Freezer" and it will start to freeze in about 10 seconds.

In addition, typical rapid freezer cool air by flowing cold air in a straight line from one direction.

Because the cold air flows in one direction, there will be parts where the cold air hits the food and parts where it doesn't.

However, the "Re-Joice Freezer" is a liquid freezer that can freeze food by placing it in liquid.

Because it freezes in liquid, it can freeze evenly and all at once.

Click here for the details page of Re-Joyce Freezer

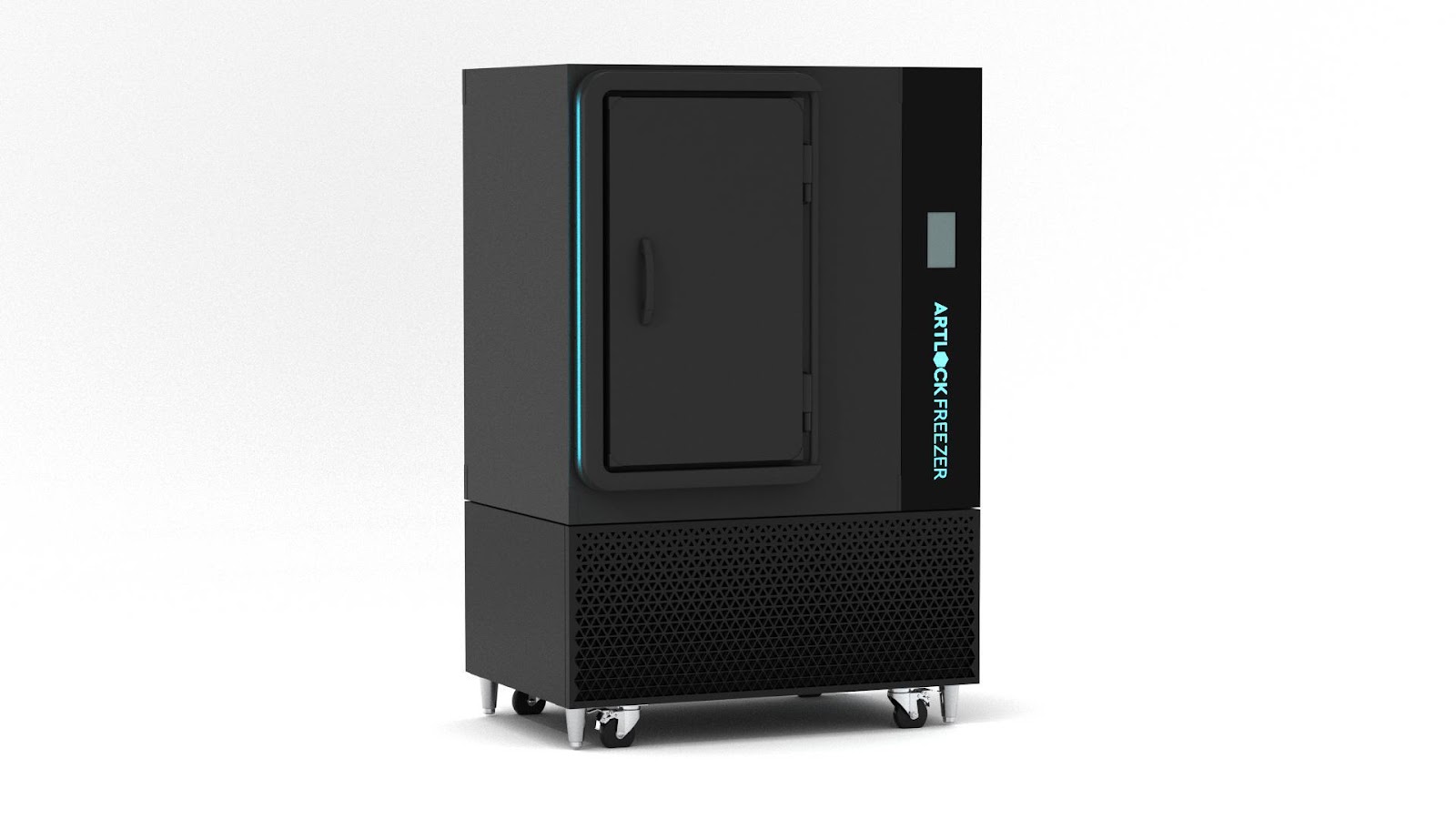

Artlock Freezer (Air Blast Freezer)

This is the industry's first freezer equipped with a fully automatic mode that allows you to freeze food at high quality without damaging it.

merit

- micro

- smart freeze

- "Full automatic mode"

"Micro Wind System" is a system developed for high quality cooling.

Conventional refrigerators have a method in which cold air flows in one direction, which poses the problem of the quality of food deteriorating due to the cold air. In the newly developed micro-wind system, cold air flows in the other direction to wrap around the food in the cooling space. As a result, it is now possible to freeze food while maintaining its high quality without damaging it.

"Smart Freeze" allows you to automatically adjust freezing settings according to ingredients, season, room temperature, etc. It automatically adjusts to the appropriate temperature according to the ingredients and seasonal conditions.

The automatic adjustment function has the advantages of `` reducing the risk of failure,'' ``reducing electricity costs,'' and ``no adjustment required.''

"Fully automatic mode" is the industry's first feature that supports the freezing process fully automatically.

With conventional freezers, the problem was that the quality of the ingredients varied depending on the person in charge of freezing the food, but with the fully automatic mode installed in the Artlock Freezer, Anyone can reproduce the same freezing conditions This prevents variations in frozen quality.

Click here for detailed page of Art Lock Freezer

Which factories are recommended for air blast freezing?

Airblast is said to be the most versatile among the types introduced in this article. Foods that could not be cooled using conventional freezers can now be rapid freezing while maintaining their quality.

Recommended factories: Food processing and pharmaceutical industries, such as sushi production factories, bread factories, seafood factories, and meat factories.

Air blasts do not require a large installation space, and some are mobile, so they are recommended for small factories.

Conclusion

In this article, we will discuss what is air blast refrigeration? We have introduced the advantages and disadvantages of air blasting.

There are four types of rapid freezer, each with a different mechanism.

We introduced the advantages and disadvantages of air blast freezing.

Advantages include `` more rapid cooling,'' ` `energy-saving measures,'' ``environmentally friendly,'' and ``no need for large installation space.''

Disadvantages are "drying effect" and "uneven cooling"

After understanding the above advantages and disadvantages, why not consider introducing air blast refrigeration?

We also introduced recommended refrigerators.

・ Re-Joice Freezer (liquid freezer)

・ Artlock Freezer (Air Blast Freezer)

Air blast refrigeration is recommended for small factories such as in-house factories and small factories because it does not take up a lot of space because it is available in compact size or mobile type.

Please refer to this article and consider installing a refrigerator without failure.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Can it be frozen? ] How to freeze milk, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/d0390cbc7a5e9a76c11d5b9eff3b4a5b.jpg)

![[Solving issues in the retail industry] Liquid freezing machines that should be introduced in supermarkets](https://shunkashutou.com/wp-content/uploads/2024/10/60172f0f261fd750c4016165c3c56cc8.webp)

![[Used in various fields] Points to note when purchasing liquid nitrogen](https://shunkashutou.com/wp-content/uploads/2024/08/864ed88d3bcf695fd1a9af88d772606c.webp)

![[Successful example of rapid freezing] Efforts of Yuko Fisheries Cooperative and regional revitalization by women](https://shunkashutou.com/wp-content/uploads/2024/10/68950ce21415f187d34a8a1d5b48956a.webp)

![[Instant cooling at -196℃] What's up with cooling equipment that uses liquid nitrogen?](https://shunkashutou.com/wp-content/uploads/2024/10/4b219d54bd662f10cbae6ea211f612dd.webp)

![[Which products are popular? ! ] Recommended frozen food ranking](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-ranking-1024x682-1.jpg)

![[For the lunch box manufacturing industry] Business issues can be solved by using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/04/f93f171f5d29bdb15c4b8d06e244b002.jpg)

![[Achieving instant freezing at home] The evolving freezing function of home refrigerators](https://shunkashutou.com/wp-content/uploads/2015/10/93e403bcf18bda6b2d63c7c74fdef064.jpg)

![[Easy installation and bulk storage] Prefabricated freezer functions and prices](https://shunkashutou.com/wp-content/uploads/2015/09/e52a1bacf6f05c6337143048f88802d7.jpg)