What is a blast chiller? A thorough explanation of the difference between shock freezers!

Blast chillers are now commonplace in restaurants and food factories.

“Everyone around me uses it a lot, but what is a blast chiller?”

"What is the difference between a blast chiller and a shock freezer? I don't know which one to buy..."

There may be many people who have such problems.

A blast chiller is a machine that rapidly cools food, and is different from a shock freezer, which quickly freezes food.

However, there are blast chillers that can also be used as shock freezers, and there are many different manufacturers and models, so it can be difficult to know which one to choose.

If you choose the wrong machine, you may find that when you put food in it, it doesn't get cold at all.

In order to avoid such situations, we, who have consulted over 6,000 companies regarding food cooling and freezing, will explain in detail what a blast chiller is and how it differs from a shock freezer. Masu!

目次

What is a blast chiller? What are the benefits?

A blast chiller is a machine that rapidly removes the rough heat from food by blowing powerful cold air at it.

Major manufacturers such as Fukushima Galilei and Panasonic are famous, and they are mainly used in food manufacturing sites such as restaurants, food factories, and hotels.

There are three main advantages to using a blast chiller:

① Improved safety

②Improvement of provision quality

③Improving efficiency

① Improved safety

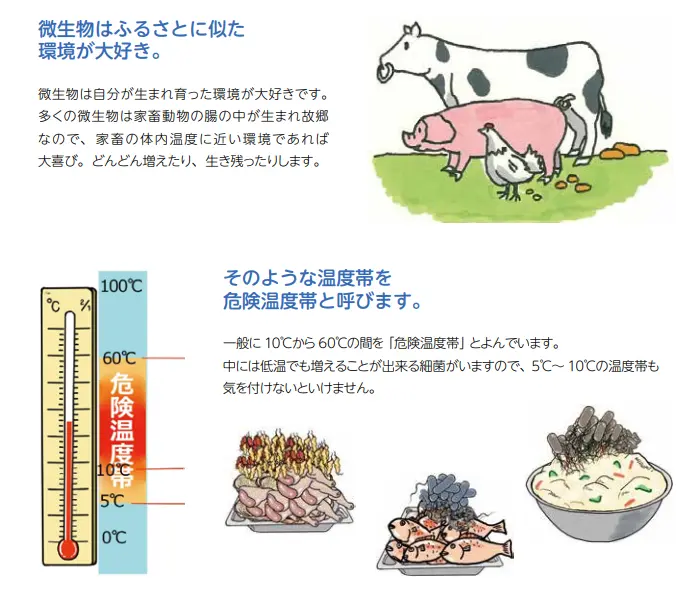

It is known that bacteria that cause food poisoning can easily breed in the temperature range that food passes through after cooking, which is close to the animal's body temperature.

According to the Ministry of Health, Labor and Welfare's Food Sanitation Management Guide, the temperature range of 10 to 60 degrees Celsius is called the dangerous temperature range, where bacteria can easily breed.

Also, some bacteria breed easily at low temperatures, so measures should be taken in the temperature range of 5 to 10 degrees Celsius.

Source: https://www.mhlw.go.jp/file/05-Shingikai-11121000-Iyakushokuhinkyoku-Soumuka/0000169562.pdf

Therefore, in order to ensure food safety, it is important to know how quickly food can pass through this temperature range.

This is a concept that has now become commonplace in food hygiene management, and the Ministry of Health, Labor and Welfare's ``Hygiene Management Manual for Mass Cooking Facilities'' states that ``take measures to lower the core temperature to around 20℃ within 30 minutes.'' It has been.

With the blast chiller, food at approximately 90°C can be input and rapidly cooled down to 3°C.

For example, a jelly that takes about two hours to cool and harden in the refrigerator can be hardened in about 30 minutes using a blast chiller.

By using a blast chiller, you can quickly cool food, which in turn can inhibit the growth of bacteria.

②Improvement of provision quality

Source: http://www.tokyo-cooks.jp/information/2012042711120150.html

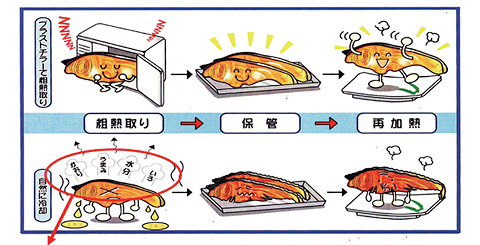

Normally, if you let food cool down naturally over time, the moisture in the food will be lost and the food will become dry.

At the same time, the flavor after cooking is lost, and the deliciousness of the freshly made food is lost.

However, if you use a blast chiller, you can significantly reduce the time required for cooling, which prevents the food from drying out and losing its flavor to a certain extent, allowing you to get the taste closer to freshly made food.

③Improving efficiency

Blast chillers allow rapid cooling, which can significantly reduce work efficiency.

Using the example of jelly that I introduced earlier, before we introduced the blast chiller, we had to wait two hours for cooling before moving on to the next process, which resulted in poor work efficiency.

It also requires space to store it, which limits the amount you can make.

However, by introducing a blast chiller, the time required for cooling is reduced to about 30 minutes, so you can move on to the next process immediately, and there is no need to create additional space for cooling.

Therefore, the introduction of a blast chiller will lead to improved efficiency and effective use of space.

Blast chillers improve the safety and efficiency of cooking, but they are often talked about together with shock freezers.

So, what is the difference between a shock freezer and a shock freezer?

What is the difference between a blast chiller and a shock freezer?

The difference between a blast chiller and a shock freezer lies in their different purposes.

A blast chiller is a machine whose purpose is to rapidly cool food, while a shock freezer is a machine whose purpose is to rapidly freeze cold food.

To explain the difference in functionality specifically, a blast chiller is a "rapid chiller" that can rapidly cool food at approximately 90°C to 3°C.

On the other hand, a shock freezer is a "rapid freezer" that can rapidly freeze food that has already lost its heat to -18℃.

Each has a different design for different purposes, so they can be used differently.

However, there are also blast chillers on the market that are equipped with shock freezer functions, and there are machines that can be used in multiple ways.

This means that food at approximately 90°C can be rapidly cooled and then frozen to -18°C in one go.

It is a very convenient machine as there is no need to prepare a shock freezer separately from the blast chiller.

“In that case, I think it would be a good idea to choose a blast chiller and freezer that can also freeze food.”

You may think so, but it's actually not.

Just like different types of machines, each has its own advantages and disadvantages.

Blast chillers and shock freezers are quite expensive machines, so if you don't carefully understand the advantages and disadvantages when choosing a machine, you may end up regretting it later.

So, next we will explain what points you should consider when choosing a machine, and how to avoid making mistakes when purchasing!

How to choose without making mistakes when purchasing!

We will explain how to choose a blast chiller or shock freezer without making mistakes, but there is one point that is most important.

The question is, ``Do you want to freeze as well as cool?''

If cooling is sufficient, we recommend choosing a blast chiller.

What if you also want to freeze it?

“A blast chiller with a shock freezer function looks great!”

You may think so, but I actually don't recommend it.

Since two originally different functions are installed in one machine, there are of course disadvantages.

Broadly speaking, there are three types:

① Considerable load is placed on the machine

②Productivity decreases

③Unhygienic

① Considerable load is placed on the machine

Refrigerators are usually not designed to cool hot food.

If hot food is frozen using this design, the refrigerator will require more power than it can originally produce, resulting in unreasonable operation.

Naturally, this places a considerable load on the machine, increasing the risk of failure and shortening the life of the machine.

Therefore, when cooling and freezing are performed all at once using one machine, a corresponding load control system is required.

However, many blast chillers with shock freezer functionality don't take that into account, so they can end up being expensive purchases in the long run.

②Productivity decreases

When using a refrigerator, the problem of frost formation always occurs.

When food is frozen, the moisture contained in the food and the air forms frost and adheres to the freezer.

If you operate the machine with frost still on it, it may cause a malfunction, so it is necessary to defrost it at some point after freezing.

Defrosting is performed using the heater function, so during that time the refrigerator stops operating and production also stops.

Also, food naturally has more moisture when it's warm, so if you put it into the refrigerator while it's still warm, it will frost almost twice as much as normal.

As a result, the number of defrosting operations required increases, resulting in a significant drop in productivity.

③Unhygienic

As we explained earlier, many blast chillers with shock freezer functionality do not take refrigeration into consideration.

The same can be said about the parts that make up machines.

This can be clearly seen in the thickness of the panel.

The thicker the panel, the more difficult it is for cold air to escape, but since a blast chiller only needs to cool, the panel doesn't need to be that thick.

If the product is used for freezing as designed, it will not be able to retain the cold air when it enters the freezing temperature range, making it difficult to cool down.

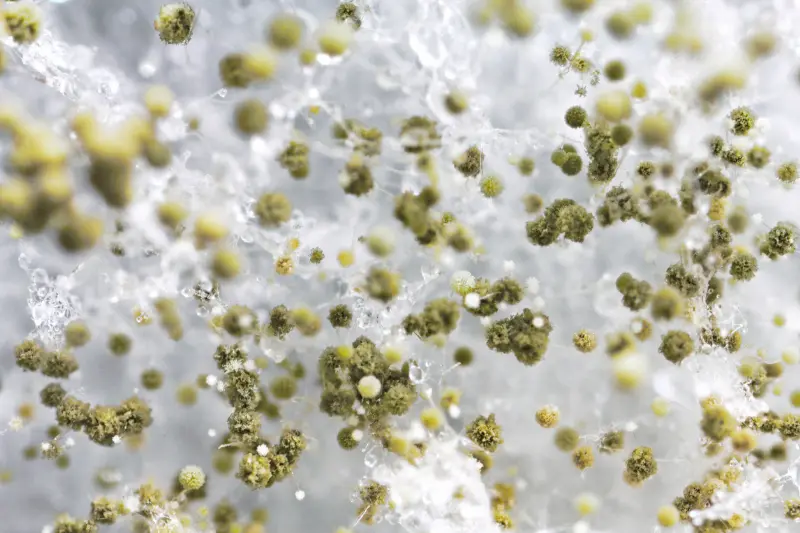

Additionally, because the outside air and the air inside the refrigerator are not completely separated, the temperature difference causes condensation to form on the panels.

If you don't thoroughly wipe off condensation or clean your home frequently, mold will grow, which can become a hygiene problem.

Therefore, if you want to freeze as well as cool, it is important to choose a machine based on the following points.

1. No load is placed on the machine even if it is poured while hot.

2. Frost does not easily form on the refrigerator part.

3. Designed for refrigeration

To summarize how to choose without making mistakes, if you only need cooling, we recommend a blast chiller.

If you also want to freeze the food, we recommend choosing a machine that is designed for freezing, as it will not put a load on the machine even if you put the food in while it is still hot, and that frost will not form on the freezer part.

However, if you also want to freeze food, what kind of machine should you choose?

So next, we will introduce you to our recommended rapid freezer with blast chiller function!

We explain recommended models along with how to use them!

I have explained that the following three points are important if you want to cool and freeze at the same time.

① No load is placed on the machine even if it is put into the machine while it is still hot.

② Frost does not easily form on the refrigerator part.

③ Designed for refrigeration

There is rapid freezer with a blast chiller function that satisfies all of the above.

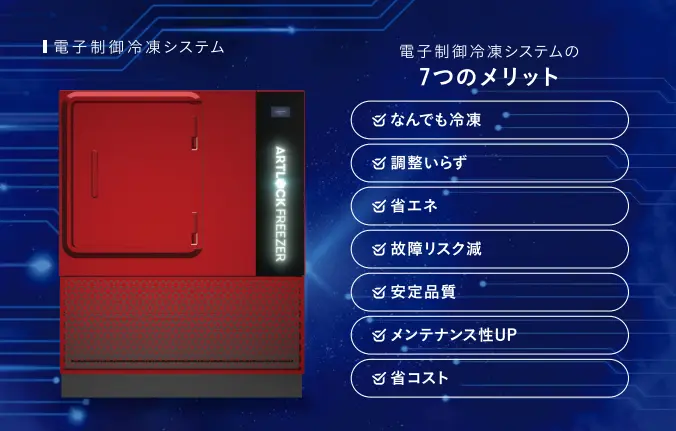

That is "ARTLOCK FREEZER".

``ARTLOCK FREEZER'' is actually not a blast chiller, as the name suggests, but a type of rapid freezer.

However, with an electronic control system and anti-frost mechanism that other refrigerators do not have, it can cool hot foods at the same time.

We will explain in detail why "ARTLOCK FREEZER" is recommended, along with the machine's features.

Electronic control system to minimize load on the machine

ARTLOCK FREEZER detects the internal environment and outside temperature, and automatically controls the operation to ensure optimal operation.

Normally, when you put hot food into a freezer, it requires more power than the freezer can normally produce, causing it to run unreasonably.

This places a considerable load on the machine itself, shortening its lifespan.

In contrast, with ARTLOCK FREEZER, the electronic control system minimizes the load on the machine.

Therefore, you can continue to use the machine without shortening its lifespan even if you just feed cooked food into the machine.

This electronic control system using AI is an industry-first feature not found in other refrigerators.

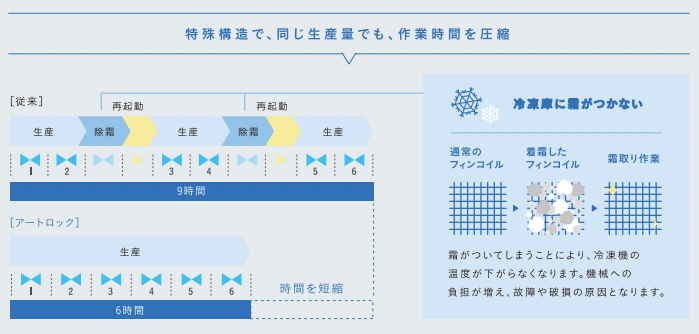

Anti-frost mechanism significantly improves productivity by preventing frost from forming

ARTLOCK FREEZER has a design that makes it extremely difficult for frost to form on the refrigerator, and it can operate continuously for up to 72 hours.

With other refrigerators, when operating for a full day, it is necessary to allow time for defrosting several times, which causes production to stop.

However, with ARTLOCK FREEZER, there is no need for defrosting after one day of production, so it can continue to operate for a whole day.

Productivity is greatly improved as there is no need to stop the operation of the refrigerator.

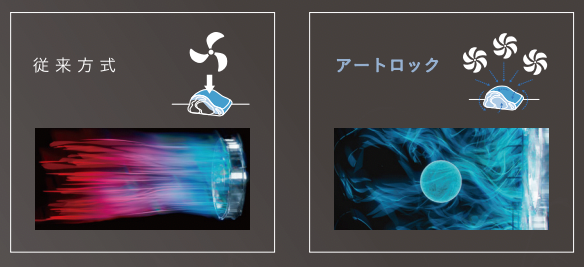

Micro-wind system that suppresses dryness and unevenness

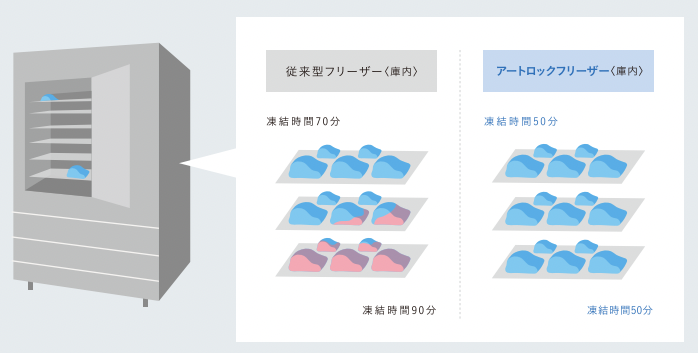

ARTLOCK FREEZER is not just rapid freezer, it is a freezer that focuses on high-quality freezing.

What makes this possible is a micro-wind system that generates minute turbulence.

Regular blast chillers and shock freezers are the same in that they blow cold air onto food to remove heat, but the difference lies in how the air is generated.

Blast chillers and shock freezers use large fans to generate strong wind and direct the wind from one direction.

If this happens, the strong winds will inevitably cause the food to dry out or become damaged, such as cracking.

Also, since the air is blowing from one direction, it is difficult for the air to blow to areas far from the fan, resulting in uneven air flow.

However, ARTLOCK FREEZER uses multiple small fans to generate wind, so it is possible to generate minute turbulence.

The humidity is also quite high, which prevents the meat from drying out and cracking, making it possible to freeze it without damaging it.

Furthermore, because it is filled with fine air, it can be frozen evenly no matter where it is placed.

In addition to the above functions, it is designed for high-quality freezing, so of course there are no issues with the thickness of the panels.

Therefore, ARTLOCK FREEZER can be said to be the only freezer that can cool even hot food without any problems.

It is also very easy to use, just turn it on and start pre-cooling 30 to 1 hour before use.

Once the temperature inside the refrigerator has fallen from room temperature to -35℃, you can simply put food in and take out the frozen food 30 to 1 hour later.

It is also much easier to work with since there is no need to vacuum pack or other packaging before freezing.

With ARTLOCK FREEZER, you can cool and freeze freshly baked bread, freshly fried tempura, and more while keeping them piping hot and delicious.

It has become a very popular model because it can reproduce the piping hot deliciousness as it is.

Conclusion

How was that?

We explained what a blast chiller is and the difference between a blast chiller and a shock freezer!

A blast chiller is a machine that rapidly removes crude heat from food by blowing strong air at it.

The original purpose and design of this freezer was different from that of a shock freezer, which rapidly freezes cold food.

Blast chillers with shock freezer functions also exist, but they are not recommended as freezing hot foods will put a considerable load on the machine and require additional defrosting.

Therefore, if you want to freeze as well as cool, it is important to choose a machine based on the following points.

① No load is placed on the machine even if it is poured while hot.

② Frost does not easily form on the refrigerator part.

③ Designed for refrigeration

``ARTLOCK FREEZER'' satisfies these conditions.

With ARTLOCK FREEZER, you can cool and freeze food at the same time, allowing you to recreate the piping hot deliciousness.

We can test it for free to see how well it reproduces when you actually put hot food in it, so please feel free to contact us!

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[For food manufacturers] What is the meaning of IQF freezing and what is rapid freezer required for it?](https://shunkashutou.com/wp-content/uploads/2017/03/40008d9f1a752dd006399fe1c4beda34.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![[Wholesale] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_oroshi_img_01.jpg)

![Explaining how to freeze garland chrysanthemums with photos! [Defrosting and storage period, 5 recipes]](https://shunkashutou.com/wp-content/uploads/2023/10/syungiku-catch-768x512-1.jpg)

![[Explanation with photos] How to freeze peaches, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/b454a38d482a64b14d55d2560aa4193a.jpg)

![How to freeze tomatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/tomato-768x513-1.jpg)

![[How long does it last? ] How to freeze cooked rice and how long it can be stored](https://shunkashutou.com/wp-content/uploads/2023/10/7e31499b015d58f220536e3274a41bf2.jpg)

![[Make frozen oysters even more delicious! ] Correct thawing method and usage recipes](https://shunkashutou.com/wp-content/uploads/2023/10/5855c6e6d6dbdb298f86405b4b522329.jpg)

![How to freeze zucchini and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/zucchini6-768x512-1.jpg)

![[Solving freezing problems] Performance and price of Re-Joice Freezer](https://shunkashutou.com/wp-content/uploads/2015/06/c808eaf7291922d0d2620606010122fe.jpg)

![How to freeze bitter gourd and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/8fe0cb793c93d4fd4c26f352d17e5b87.jpg)

![[Commercial rapid freezer] Explaining the features, size, and price of Panasonic rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/01/panasonic.jpg)

![Introducing how to freeze/thaw salmon roe and how long to store it [includes carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/09/236b884b68d07d2f5983f2b9ea66583d.jpg)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2016/06/09c17e4deeb1ac0cdc5a513eaf89ab1a.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Nutrition remains the same! ? ] Introducing how to use frozen vegetables and recommended recipes](https://shunkashutou.com/wp-content/uploads/2023/10/vegetables-reito-1-1-768x511-1.jpg)

![[Introducing tricks and time-saving techniques! ] How to freeze ginger-yaki, carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/10/ef145c31655c5774469e05b5e892207b.jpg)

![[Recommended for lunch boxes too! ] Introducing recipes and methods for freezing pasta!](https://shunkashutou.com/wp-content/uploads/2023/10/93f66b71b92cbe1085d41c4ed80d7726.jpg)

![[Can it be frozen? ] Introducing recipes and methods for freezing avocados!](https://shunkashutou.com/wp-content/uploads/2023/07/7b25b2d45ff983fca2a15b6ad7edf369-1.jpg)

![[Explanation with photos! ] Introducing the method and recipe for freezing komatsuna](https://shunkashutou.com/wp-content/uploads/2023/09/5d2a19a6e6cfb5ad0329d8fce162f292.jpg)

![[Introducing trick techniques! ] How to freeze and thaw pancakes](https://shunkashutou.com/wp-content/uploads/2023/09/4f2e9d04709f0c4e5c1769985a49ac8b.jpg)

![[Explanation with photos! ] Shiitake mushroom freezing method and storage period, 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/shiitake-768x512-1.jpg)

![Types of rapid freezer and purchasing points! [Examples of failures in machine selection! ? ]](https://shunkashutou.com/wp-content/uploads/2015/04/e68b2ac878e110c2a4639a33271057d1_s-1.jpg)

![[Thorough guide to preserving meat] Preservation methods, expiration dates, thawing methods, rapid freezing](https://shunkashutou.com/wp-content/uploads/2023/09/ec61889773cfed9c75aa97d9ca6c96dd-1.jpg)

![[Long-lasting freshness! ] Explaining the advantages and disadvantages of chilled storage and chilled transportation](https://shunkashutou.com/wp-content/uploads/2016/11/64b437bd976e4ef73a85dbb64cdf9fc8.jpg)

![Shock freezer prices and reasons why we can't recommend used ones [What's the difference from a blast chiller? ]](https://shunkashutou.com/wp-content/uploads/2019/09/f76c6907f41d0b092e20d0924e5f27c9.webp)