[Is it actually something familiar? ! ] Types of flash freezing and their temperatures

What temperature does it mean to freeze instantly?

At extremely low temperatures, many things freeze instantly.

As for familiar items, you may think of insecticide sprays with a high cooling capacity of -40℃ and dry ice with a temperature of -79℃.

Liquid nitrogen, which is in high demand industrially, is used in a wide variety of fields because of its excellent cooling capacity of -196℃.

Particularly in the field of food freezing, its use has progressed and it has been established as one of the quick freezing technologies.

There are various freezing methods for quick freezing, and it is an essential technology for freezing food.

目次

Instant freezing insecticide spray

There are sprays on the market that do not contain insecticidal ingredients and are used to exterminate insects such as stink bugs, cockroaches, and centipedes.

This is an insecticide that sprays a spray cooled to -40℃ and freezes it instantly. It efficiently removes heat from the surface of the insect's body and puts it in a state of suspended animation, but what kind of cooling method is used?

The method is cooling using the heat of vaporization.

Heat of vaporization is the energy required to change from a liquid to a gas while absorbing heat from its surroundings.

For example, when you apply alcohol to your skin, the sensation of a tingling sensation occurs because the alcohol takes away heat from your skin as it evaporates. If the liquid has a low vaporization temperature, a higher cooling effect can be obtained.

Insecticide sprays that freeze instantly contain liquefied gases such as propane and butane, and isopentane as their main ingredients.

The boiling point of propane is approximately -42°C and that of butane is -0.5°C, so if these gases are packed at high pressure into a spray can and injected, they have a high cooling effect.

The boiling point of isopentane is 28°C, so it does not vaporize when it is injected.

However, since its boiling point is about the same as room temperature, it evaporates quickly and has the effect of immediately lowering the surface temperature of the object it is sprayed on.

In this way, the two types of gas efficiently remove heat and cool the insects all at once.

How effective are instant-freezing insecticide sprays?

Spraying for about 3 seconds at a room temperature of 34°C can cool the target to nearly -20°C. There are differences in cooling capacity depending on the product, but there are sprays that can cool down to around 10℃ and sprays that can cool down to around -35℃.

Colder than dry ice! Liquid nitrogen flash frozen at -196℃

Dry ice is one of the most powerful cooling substances.

Ethanol and dry ice can be used to create a liquid that is cold enough to instantly freeze anything.

The freezing temperature of ethanol is -117℃, so it will not freeze even if you put dry ice at -79℃. Since it is a liquid with an extremely low temperature, it can instantly freeze something you put in it.

For example, oily foods such as sesame oil and mayonnaise, as well as bananas, freeze quickly.

Liquid nitrogen is a substance that has a greater cooling capacity than dry ice and is used industrially.

Liquid nitrogen is nitrogen that has been cooled to -196°C and liquefied.

Because it has an extremely low temperature, it is used to cool a variety of things and is the most widely used industrial gas.

Liquid nitrogen is used in a wide range of fields.

For example, it is used in the medical field as a dermatological treatment. This treatment involves cooling warts and other deformed areas with liquid nitrogen to kill cells and tissues.

In the metal processing field, it is used for heat treatment in the production of semiconductors and metal compounds, as a refrigerant in low-temperature physics experiments, and in freeze-grinding.

It is also used in the cryopreservation field to freeze specimens, blood, and special substances.

Flash freezing method also used for freezing food

Liquid nitrogen is used in various fields, but most of all it is used in the field of food freezing.

Food can be frozen instantly by spraying it with liquid nitrogen. Because food is frozen all at once, it is sometimes referred to as flash freezing, but more accurately it is a technique called rapid freezing.

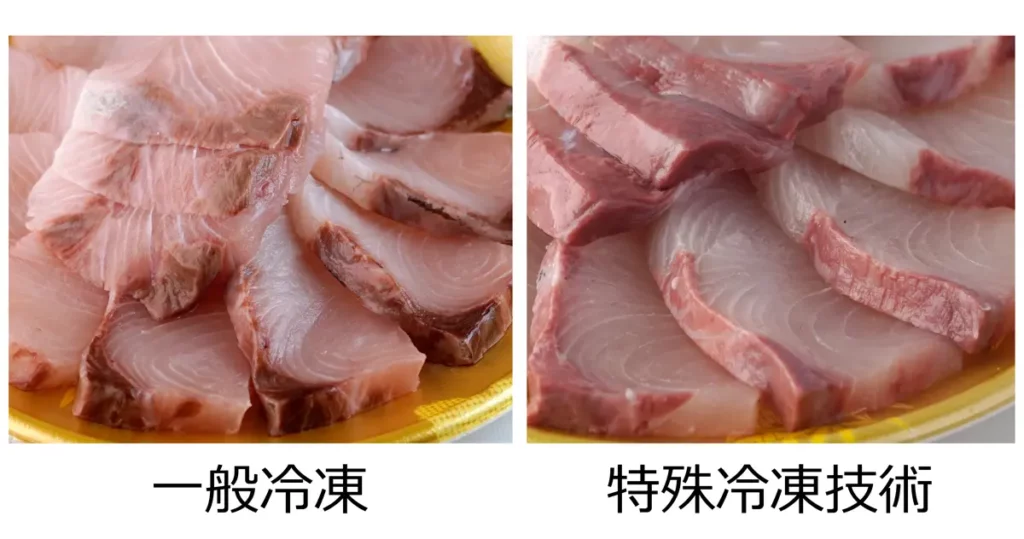

The method of freezing food in a regular freezer is called slow freezing, but the difference between slow freezing and rapid freezing is the freezing speed.

The purpose of rapid freezing is to cool the food all at once, allowing the water in the food to quickly pass through the freezing temperature range.

If food is frozen using slow freezing, which is a common freezing method, the texture and flavor will deteriorate and the quality will deteriorate.

The reason for this is that slow freezing cools the food slowly, so when the water in the food turns into ice crystals, the volume expands and destroys the cells in the food.

The umami components along with water flow out of the destroyed cells, resulting in a deterioration of quality.

Rapid freezing allows food to quickly pass through the freezing temperature range of -5°C to -1°C, suppressing the growth of ice crystals.

As a result, cell destruction can be prevented and food can be frozen without deteriorating its quality.

In this way, rapid freezing allows food to be frozen for long periods of time while preserving its quality, freshness, and taste.

Quick freezers offer numerous benefits, such as reducing waste and enabling more efficient production, so they are increasingly being introduced in a variety of places, including food processing plants, restaurants, and supermarkets.

For example, at restaurants that serve noodles such as udon, pasta, and soba, it is difficult to store raw noodles if they are unsold.

However, with frozen noodles that are quickly frozen, you can use the amount you need whenever you need it.

You can provide noodles that are just as delicious as fresh noodles without wasting any waste.

Also, in a cake shop, it is a lot of work to make many kinds of sweets every day.

By quick freezing, you can make several types of cakes in one day, store them frozen, and then thaw and serve as needed.

This makes it possible to efficiently produce many types of sweets.

There are many types of quick freezers that use a variety of freezing methods other than liquid nitrogen.

Liquid nitrogen is difficult to handle and requires proper storage facilities, so it is mainly used in large food factories.

We would like to introduce a quick freezing machine that is easy to install and operate.

This is an air blast freezer that uses cold air, just like a regular freezer.

Freeze by blowing cold air at -30℃ to -40℃.

Among them, the Art Lock freezer is equipped with a micro-wind system, which can minimize deterioration of ingredients (drying, cracking, etc.).

This prevents the surface from scattering or drying out due to cold air, so the product can remain in the same condition as before it was frozen.

A freezing machine that combines cold air, magnets, and electromagnetic waves.

Like air blasting, it uses cold air of -30℃ to -40℃ and the power of magnetism to achieve high-quality freezing.

Re-Joice Freezer freezes vacuum-packed foods by immersing them in an alcohol solution cooled to -35°C.

Liquid has a thermal conductivity 20 times higher than air, so it freezes faster and is more efficient at cooling.

In addition, as the liquid is stirred, uneven freezing is prevented and the food can be frozen evenly.

Conclusion

Do you understand the types of flash freezing and their temperatures?

By cooling to extremely low temperatures, it can be frozen instantly.

Instant freezing technology is especially used in the food freezing field, so it can be said that it has become an ingrained part of our lives.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Achieving instant freezing at home] The evolving freezing function of home refrigerators](https://shunkashutou.com/wp-content/uploads/2015/10/93e403bcf18bda6b2d63c7c74fdef064.jpg)

![[Solving freezing problems] Performance and price of Re-Joice Freezer](https://shunkashutou.com/wp-content/uploads/2024/10/6bf8562954d67708f4b7808011fa9245.webp)

![[Eliminating the labor shortage! ] Introducing the benefits of the cook-freeze system!](https://shunkashutou.com/wp-content/uploads/2018/12/72352e99f79e7f2bfa6e9eca24acceb0.webp)

![[Used in various fields] Points to note when purchasing liquid nitrogen](https://shunkashutou.com/wp-content/uploads/2024/08/864ed88d3bcf695fd1a9af88d772606c.webp)

![Types of rapid freezer and purchasing points! [Examples of failures in machine selection! ? ]](https://shunkashutou.com/wp-content/uploads/2015/04/e68b2ac878e110c2a4639a33271057d1_s-1.jpg)