[For the lunch box manufacturing industry] Business issues can be solved by using rapid freezing!

In recent years, with the increase in demand for ready-made meals, it is thought that the demand for bento boxes that can be easily eaten at home will continue to increase.

but,

"It's difficult to make different types of side dishes every day because you can't make them in advance."

"I can't increase my repertoire of side dishes because I don't have the manpower or time..."

“It is difficult to predict supply and demand for lunch boxes, and we are unable to respond to sudden orders.”

Are there any business owners who have this kind of problem?

Lunch boxes move quickly, and as planned production is not possible, waste is a major problem.

However, all of these problems can be solved by "rapid freezing".

This time, we will introduce effective ways to use and types of "rapid freezing," which has various benefits such as improving business efficiency and increasing sales.

This is a must-see for those who want to reduce the time and effort required to prepare bento boxes, those who want to eliminate opportunity loss and waste loss, and those who want to expand their bento sales channels, so please read until the end.

目次

What are the problems with frozen lunch boxes?

The biggest issue with frozen lunch boxes is "quality after thawing."

Freezing and thawing a completed bento can cause the following problems.

- Drips (moisture containing flavor components and nutrients) come out from each ingredient.

・In addition to drying out the food, it also causes uneven freezing, which causes variations in quality and causes complaints.

・Since lunch boxes are often eaten some time after thawing, the recovery rate of each ingredient is low with slow freezing (normal freezing), resulting in a lunch box that is far from the quality before freezing. .

Frozen bento boxes had the following issues.

Ask about freezing lunch boxes

Challenges faced by bento shops

Issues in bento manufacturing include the following:

1. We are unable to respond to sudden large orders for events and location valves due to a lack of manpower. When dealing with such situations, labor costs are high as they have to work day and night.

2. Demand for bento boxes can change due to small things such as the weather or train delays, making it difficult to predict supply and demand, leading to waste.

3.Manufacturing a large number of products takes time and effort to prepare. This increases labor costs and lengthens working hours.

4. Unable to find cooks and lack of manpower, unable to expand store openings or mail-order sales.

5. Existing refrigeration operations cannot provide high quality products.

However, all of these concerns can be solved by "rapid freezing ".

It is true that ``refrigeration'' has a negative image. rapid freezing overturns this impression of freezing and makes it possible to maintain high quality.

So, how can the problem be solved by actually introducing rapid freezing? Let's look at it in detail next.

View materials on rapid freezing

Why does rapid freezing maintain high quality?

Frozen lunch boxes are generally

・Drips (moisture containing flavor components and nutrients) occur

・(Depending on the air flow in the freezer) The quality of each ingredient may vary.

・Food is dry and has a dry texture

・Recovery rate of food after thawing is low

There are issues such as:

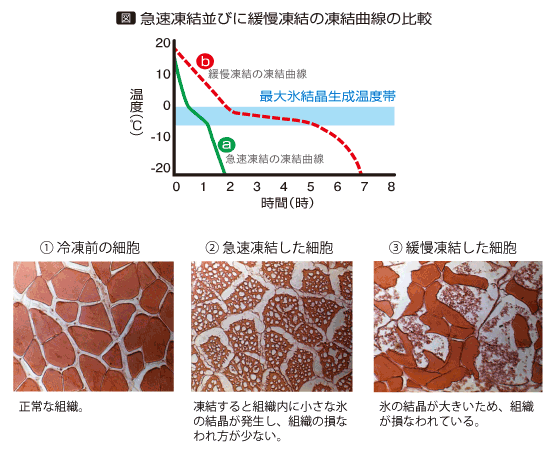

Why does slow freezing (normal freezing) cause such problems?

The water inside food cells freezes and turns into ice crystals. In slow freezing (normal freezing), water freezes and expands slowly, resulting in large ice crystals.

The larger ice crystals then break through the food cells from the inside, creating holes in the cells. These holes are a major cause of deterioration in food quality.

When frozen food is thawed, flavor components and nutrients leak out along with the water through these holes and are lost. This is called drip.

The temperature range where the water in food crystallizes is called the "maximum ice crystal formation temperature range", and the quality of the food after thawing is determined by how quickly it passes through this temperature range.

rapid freezing allows cells to pass through this temperature range much more quickly than slow freezing, so cells can be frozen without being destroyed.

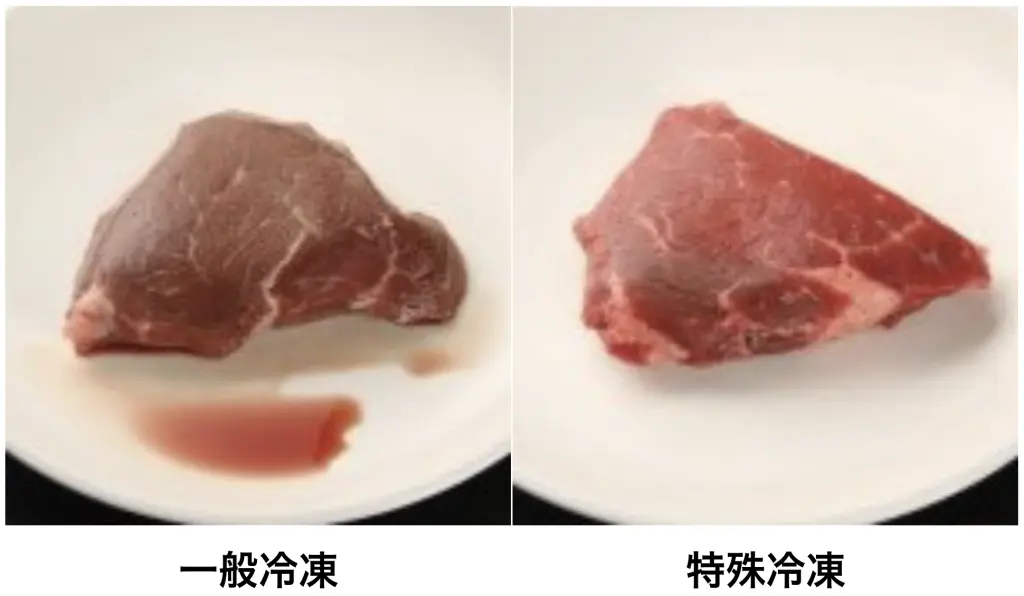

Therefore, food that has been frozen without cell tissue being destroyed has almost no drips when thawed, and can be returned to a state that is almost the same as before freezing, maintaining its freshness, texture, and flavor.

Furthermore, rapid freezer we handle solve the problems of "drying of food" and "uneven quality" that ordinary rapid freezing could not solve.

We would like to introduce you to rapid freezer we handle.

Artlock freezer (air freezing)

・Micro window system

・Electronic control system (smart freeze)

・No need to defrost

【merit】

Equipped with a micro-wind system, it suppresses damage to food (drying, cracking, oxidation, etc.) that occurs during freezing, and enables high-quality freezing.

By creating a well-balanced flow of fine air inside the refrigerator, uniform quality can be maintained without uneven freezing.

Because food can be frozen naked, there is no deformation or discoloration during packing.

You can freeze food without cooling it, improving operational efficiency.

Rejoice freezer (liquid freezing)

・Liquid such as alcohol is the medium

・Packing required

【merit】

Freezing speed is fast because liquid with high thermal conductivity is used as a medium. Although it requires packing, it can also be an advantage if you consider how to use it afterwards.

The optimal rapid freezer and freezing/thawing method for each ingredient vary greatly. Please feel free to contact us.

What can be achieved with rapid freezing

With the introduction of rapid freezer, we are now able to keep food in its delicious state. This typically accomplishes the following:

Improve sales by expanding sales channels

Started selling through mail order and wholesale. By rapid freezing freshly made products, we can provide them with almost the same quality even after thawing.

Eliminating labor shortages

Planned production will become possible, and employees will be able to work in a stable manner throughout the year. Employee retention rates have increased, and we no longer have to worry about labor shortages.

Improving work efficiency

Refrigeration efficiency has been improved, making it possible to freeze faster than existing refrigeration equipment. In addition, since there is no need to defrost products, products can be frozen even during times when operations could not be performed, increasing production volume.

Eliminating food waste

rapid freezing allows you to preserve products that maintain their quality for a long period of time, making it possible to stock products. By always ensuring inventory, we prevent opportunity loss and also reduce waste loss.

In addition, by rapid freezing, it can be sold nationwide.

Improving food quality

Normal freezing methods often fail to reproduce satisfactory quality, such as leakage of flavor components and discoloration. rapid freezing enables long-term storage and adds value to products.

In addition, rapid freezing of fresh fish can prevent loss of freshness. Some research has shown that frozen foods have more nutrients.

The above is generally achievable, but what kind of effects can actually be achieved in the production of bento boxes?

View materials on rapid freezing

Four effects in bento manufacturing

By using rapid freezer, you can obtain the following benefits and effects from the perspective of improving business efficiency and increasing sales.

"Business efficiency"

[Assignment 1]

Due to a lack of manpower, we are unable to respond to sudden large orders for events and location valves. Responding to these issues requires labor around the clock, which increases personnel costs. Additionally, the demand for bento boxes can fluctuate due to small factors such as the weather or train delays, making it difficult to predict supply and demand and resulting in waste.

【solution】

With the introduction of rapid freezing, it is now possible to make ahead of time.

By preparing the items when you have time, you can handle large orders for events and other occasions. In addition to eliminating opportunity losses, the ability to utilize free time also leads to a reduction in personnel costs.

Furthermore, it has become possible to supply according to detailed demand, and waste loss has been reduced.

[Assignment ②]

There are many items to be manufactured, and it takes time and effort to prepare them. This increases labor costs and lengthens working hours.

【solution】

Introducing rapid freezing has streamlined the bento manufacturing process. In particular, by preparing and stocking time-consuming products such as tempura and fried foods in advance, daily operations become more efficient.

By making the food in bulk, freezing each item, and serving each side dish at the end, daily preparation work can be simplified and time taken.

It is also possible to freeze the entire bento you have made. Eliminates long working hours and increases employee retention rate!

"Sales increase"

[Assignment ③]

Unable to find cooks, the company is unable to expand its scale by opening stores or selling online.

【solution】

By making a batch at once and freezing it, it can be made by a small number of people. In addition, we are now able to sell our products through mail order, allowing us to provide our products to customers far away.

Expanding sales channels will lead to a significant increase in sales.

[Assignment ④]

Existing refrigeration operations cannot provide high quality products.

【solution】

With conventional freezing, the quality inevitably deteriorates, but by introducing rapid freezer, we can provide products that are almost the same quality as before freezing.

Furthermore, it is possible to add value to products by taking advantage of the inherent strengths of freezing, such as long-term storage and easy eating by simply thawing.

Other things you can do include:

・No preservatives or additives

rapid freezing allows products to be stored for long periods of time without the use of preservatives or additives, making it possible to target consumers who are concerned about food additives. Quick freezing allows you to retain nutrients that are lost during rapid freezing freezing (ordinary freezing), making it possible to provide lunch boxes with high added value that focus on nutrition and health.

·Take-out

By using rapid freezing for takeout at restaurants, etc., you can provide products without making customers wait.

See examples of rapid freezing

How to use rapid freezer that is effective for making bento boxes

By manufacturing and stocking products, you can reduce the effort and time required for preparation. Here is an example of how rapid freezer can be effectively used in bento manufacturing.

① Freeze the entire lunch box

◎Can be manufactured and provided without changing existing operations.

② Divide into small containers and freeze.

◎Since each container can be manufactured in large quantities, it is easy to put it into packaging materials, increasing efficiency. Because it is simplified, it can be manufactured even if there are few cooks.

③ Separate and freeze each item

◎Easy to use for preparing bento boxes to sell at stores. There is no need to make any major changes to the operation as the process is ``manufacturing each item → freezing each item → packaging them at the time of delivery.''

We have introduced three ways to use it, but the best way to use it will differ depending on the quality and operation you are looking for.

Please feel free to contact us if you would like to know more about how to use rapid freezer.

View information on rapid freezer

Conclusion

How was it?

By performing rapid freezing, it is possible to prevent waste loss and opportunity loss during bento manufacturing and improve operational efficiency.

In addition to these benefits, the time created by improving work efficiency can be used to expand your business, such as developing new menus.

Why not take this opportunity to improve your business efficiency and increase sales by introducing rapid freezer?

We are well versed in the know-how of freezing and thawing methods suitable for each ingredient, so if you would like to know more, please feel free to contact us.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![Freezing garlic, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/30693b4b122ff6c57afff367b35bc861.jpg)

![[Explanation with photos] How to freeze octopus, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/5128a2b3fa3cc254cffab87821372215.jpg)

![[Delicious frozen squid recipe! ] Tips on how to eat squid deliciously and without waste](https://shunkashutou.com/wp-content/uploads/2023/10/f3bc339b6bcaff01bd8e2aaa4257acfe.jpg)

![[Explanation with photos] How to freeze meat sauce, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/efa7161a08e57ef763d9e19623c7669c.jpg)

![[Can it be frozen? ] How to freeze cabbage rolls, storage period, and recipe](https://shunkashutou.com/wp-content/uploads/2023/10/f5c1db9a17ef7843ffd45f5ccb160ed5.jpg)

![Introducing recipes and methods for freezing spinach [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/spinachh-768x512-1.jpg)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/07/2a0deb9a6db53165f0a4938bc80cee46.webp)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![[Required for Cook Chill System] How much does a blast chiller cost?](https://shunkashutou.com/wp-content/uploads/2024/08/fc29ddca3d7d1f8d53bf99518ce28fcf.webp)

![[Delicious frozen foods] How to use them in lunch boxes, dinners, and snacks](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-1024x683-1.jpg)

![[Does alcohol freeze? ] Surprisingly unknown freezing temperature of alcohol and usage examples](https://shunkashutou.com/wp-content/uploads/2015/06/alcohol-630x420-1.jpg)

![[Rapid freezers in 2021] Market Trends and Customer Success Stories](https://shunkashutou.com/wp-content/uploads/2020/12/7F9A9CB9-A494-4E6A-946E-079279C596E6.jpeg)

![[Convenient for lunch boxes! ] How to freeze fried noodles and 5 different recipes](https://shunkashutou.com/wp-content/uploads/2023/10/yakisoba-768x512-1.jpg)

![How to freeze tomatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/tomato-768x513-1.jpg)

![How to freeze mizuna and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/b22c59559b7316b40d35d2555434791e.jpg)

![[Supervised by a nutritionist! ] How to freeze bean sprouts, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/34f4d39c30e79629a89bf54221841964.jpg)

![How to freeze cucumbers and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/37a83e91a989dfbc285ac11dede7c8c2.jpg)

![[Freezing Neapolitan] rapid freezing demonstration](https://shunkashutou.com/wp-content/uploads/2016/09/napolitan.jpg)

![[Freshly made raw soba all over the country! ] Example of introducing a quick freezer at a soba restaurant](https://shunkashutou.com/wp-content/uploads/2024/09/6d8138adcf26c410c11b25d5b8d2f3de.webp)

![[Food/processing manufacturers] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_kakou_img_01.jpg)

![[For maintaining food quality!] Three functions you should know about constant temperature and high humidity storage](https://shunkashutou.com/wp-content/uploads/2015/10/krefrigerator.jpg)

![[Explanation of functions and issues] What is partial freezing, which slightly freezes food?](https://shunkashutou.com/wp-content/uploads/2017/04/ccae917b4f7af5ace617f93280a58247.jpg)

![[Thorough explanation! ] What is the distribution and cold chain that maintains the quality of frozen foods?](https://shunkashutou.com/wp-content/uploads/2016/11/ed15366b2a889239b39608c181587427.jpg)

![[Delicious food] Solving nursing home management issues with freezing and cooling technology](https://shunkashutou.com/wp-content/uploads/2024/08/7cabe275da8be8736f4496b952bde332.webp)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2024/09/661ea3ee6264fab6520017622c656870.webp)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)