Introducing the benefits and usage examples of rapid freezer for seafood processing and wholesale businesses

Did you know that an increasing number of seafood processors are significantly increasing their profits with rapid freezer?

The latest rapid freezing technology allows freezing without causing drips or discoloration of blood.

Even fish species that are difficult to freeze, such as yellowtail, bonito, and tuna, can be stored for long periods of time without sacrificing quality.

Even seafood processing companies that had previously said they would not freeze are increasingly adopting rapid freezing, and are now using various methods to increase profits, such as `` expanding their business area,'' ``purchasing in bulk when the price is low,'' and `` selling with added value.'' There are some companies that have succeeded in increasing their capacity and are able to recover their equipment costs in less than a year.

Recently, an increasing number of seafood processing companies have introduced rapid freezer rapid freezer and some say that without them, it is essential equipment that they will not be able to compete with their competitors.

This page introduces the benefits of introducing rapid freezer for seafood processing companies. We will also introduce rapid freezer recommended for seafood processing companies and examples of their implementation.

目次

- 1Advantages of introducing rapid freezer

- 1.1 Advantage ①: You can purchase cheaply and sell it all year round (you can purchase any amount you want and sell it any time you want)

- 1.2 Advantage ②: You can create products with high added value

- 1.3 Advantage ③: You can expand your commercial area

- 1.4 Benefit ④: Food poisoning caused by Anisakis can be prevented

- 2 rapid freezer recommended for seafood processing companies

- 3 Examples of implementation by seafood processors

- 4Conclusion

Advantages of introducing rapid freezer

First, we will introduce the benefits of introducing rapid freezer for seafood processing companies.

The following four points are the main advantages.

- ① You can purchase cheaply and sell it all year round.

- ② You can create products with high added value.

- ③You can expand your commercial area

- ④Can prevent food poisoning caused by Anisakis

I will explain each in detail.

Advantage 1: You can purchase cheaply and sell it all year round (you can purchase any amount you want and sell it any time you want)

rapid freezing allows products to be preserved for long periods of time while maintaining their quality, so there is no need to worry about price reductions or waste loss due to deterioration of freshness. Therefore, you can purchase and sell at any time you like.

It is possible to stock up on high-quality fish that is in season, when the catch is high and prices are low, and sell it when it sells at a high price or when there is demand.

Example

Purchased 500kg of spiny lobster at 5,000 yen/kg in October.

At the end of the year, sell at 9,000 yen/kg and make a profit of 2,000,000 yen.

We stock a large amount of Kanburi and sell it all year round.

Developing new businesses by leveraging the ability to produce in-season quality throughout the year

ーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーー

This allows you to increase your profit margin and aim to expand your market share by differentiating yourself from other companies.

Advantage 2: You can create products with high added value.

By rapid freezing, it is also possible to create products with increased added value.

There are three points that add value when using rapid freezer: "high quality," "appearance," and "convenience."

[Point 1: High quality]

The first point in adding value is "high quality."

It is possible to maintain high quality with various types of ingredients such as fresh fish, crustaceans, and shellfish, without causing the quality deterioration (drip, discoloration, odor, etc.) that occurs with conventional freezing.

If you use rapid freezer is compatible with marine products and processed marine products, you can thaw foods that easily discolor (yellowtail, tuna, bonito, etc.) and blue fish that tend to lose their freshness without discoloring, odor, or dripping. Masu.

[Point 2: Good appearance]

The second point to add value is "appearance."

In addition to taste, appearance is also an important element that increases the value of a meal.

By using the latest rapid freezer, we can suppress discoloration and maintain the color of fresh ingredients, and we can also serve food in its original presentation.

If you use rapid freezer that does not dry out the food, you can freeze the food raw, so by freezing the food as it is arranged, you can deliver the sashimi as it is.

Some companies have succeeded by increasing added value by delivering the experience of eating sashimi rather than just delivering frozen fish.

[Point 3: Convenience]

The third point for adding value is "convenience."

Demand for products that are easy to use and provide is increasing due to labor shortages at restaurants and accommodation facilities, and situations where both parents are working and have no time for housework.

There are many examples of increased sales of processed frozen foods that are easier to prepare, as well as cooked and semi-cooked foods that can be thawed and eaten easily, even if they are a little more expensive.

In addition, products that can be frozen in bulk (IQF frozen), which can be used by thawing only the amount you want to use, have become popular because they are easy to use and do not cause waste.

In this way, by utilizing rapid freezer and adding value such as "high quality," "look," and "convenience," we can increase unit prices and differentiate ourselves from competitors to expand our market share and increase sales. It is possible to connect up.

Advantage 3: You can expand your business area

You can expand your business area by using rapid freezer.

It is now possible to rapid freezing ingredients that were previously available only in the region where they were produced, as well as the high value-added products we talked about in the previous chapter, anywhere in the world.

Therefore, it is possible to create new sales channels such as ``exporting high-quality domestically produced ingredients overseas'' and ``selling local ingredients to consumption areas such as the metropolitan area.''

In recent years, fish that previously could not be caught have been caught in various parts of Japan (such as yellowtail in Hokkaido).

There is a case study in which fish that could not be caught in the past can only be sold at a low price because people do not have the habit of eating them, but by rapid freezing and selling them to areas where there is demand, they can be sold at a higher price.

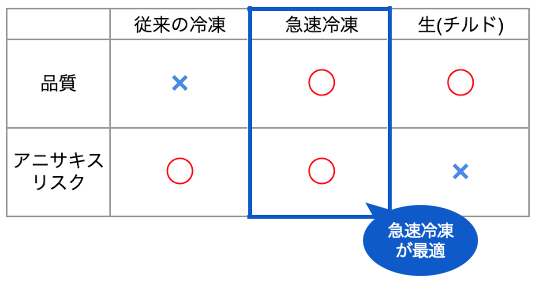

Advantage 4: Food poisoning caused by Anisakis can be prevented.

rapid freezer can also help kill Anisakis.

Anisakis is killed by freezing at -20°C for more than 24 hours. Normal freezing can kill them, but the quality will deteriorate, making it impossible to eat them deliciously.

However, with rapid freezing, it is possible to kill Anisakis without sacrificing quality.

This also solves the problem of wanting to serve sashimi but being unable to do so due to the risk of Anisakis.

So far, we have introduced the benefits that seafood processors can obtain by using rapid freezer.

So, if you actually decide to install one, what kind of rapid freezer is best?

In the next chapter, we will introduce rapid freezer are often installed in seafood processing companies.

rapid freezer recommended for seafood processing companies

rapid freezer is often installed in seafood processing and wholesale companies is the Artlock rapid freezer (air blast freezer).

There are various reasons why our products are chosen, but we will introduce the two most important ones: 1. High quality and 2. High cost performance.

①High quality

The first is "high quality."

The micro-wind system installed in the Art-Lock Freezer produces microscopic cold air.

This special airflow of fine cold air speeds up the heat exchange rate, making it possible to rapid freezing food at the highest level of freezing speed ever, without causing food to dry out.

This allows us to rapid freezing all kinds of fish in all forms, including rounds (whole fish), fillets, fillets, and sashimi, and provide them without quality deterioration such as discoloration, dripping, or odors.

Even yellowtail, tuna, bonito, mackerel, etc., which were previously considered difficult to freeze, can be stored for long periods of time without causing deterioration such as discoloration or odor.

Because we are able to produce high-quality products at the highest level ever, they are also used in Michelin-starred restaurants where the average customer spend is in the tens of thousands of yen.

②High cost performance

The second is "high cost performance."

Artlock Freezer can freeze larger quantities of food than conventional rapid freezer.

Equipped with an automatic control system called AI Smart Freeze, the freezing capacity can be enhanced by constantly adjusting the optimal settings according to the ingredients being input and the operating conditions.

In addition, the Artlock Freezer uses an anti-frost mechanism that prevents frost from forming.

With conventional rapid freezer, it is usually necessary to let rapid freezer rest for an hour to defrost once every 2.3 hours, and food cannot be frozen for about 30% of the working time.

On the other hand, the Artlock Freezer can operate continuously for up to 72 hours, and by significantly increasing the operating time of rapid freezer, efficiency can be increased by about 30%.

In this way, the AI Smart Freeze and anti-frost mechanism make it possible to rapid freezing more ingredients for the investment amount compared to conventional deep rapid freezer.

With these features, Artlock Freezer is able to achieve high-quality rapid freezing at a high cost-effective rate, making it the choice of many seafood processors.

We have products in a variety of sizes, from small models to large models, so be sure to check out our catalog as well.

Introduction example for seafood processors

From here, we will introduce case studies of companies that have introduced Artlock freezers.

Case ①: Japan Food Produce Co., Ltd.

Industry: Fisheries processing, seafood wholesale

Frozen ingredients: fish, processed seafood products

【point】

- Procure quality products at low prices without worrying about expiration dates and provide them at any time

- Expand sales by creating high value-added products with rapid freezing

- Thoroughly sell the basics of cheap things at high prices

- Recovered equipment costs within half a year after installing rapid freezer

Japan Food Produce Co., Ltd. freezes and processes purchased ingredients into high value-added products using rapid freezer, and mainly sells them wholesale to businesses, mainly restaurants.

Buy in bulk when you can get it cheaply By doing so, we can reduce purchasing costs and There is no loss”, “Preparation becomes easier”, “High quality products are always available By adding value such as “Business with high customer satisfaction and high profit margins We are realizing this.

Nowadays, more and more customers are requesting wholesale rapid freezing ingredients.

In addition, as a new business, we are selling seafood bars and e-commerce sites that use rapid freezing ingredients in all menu items.

Case ②: Fukusei Co., Ltd.

Industry: Aquaculture, processing, wholesale

Targets to be frozen: sea bream, tiger puffer fish, etc.

【point】

- Succeeded in creating high value-added products with Artlock Freezer

- Having business for both merchants and consumers allows us to respond to changes in external factors (such as the coronavirus)

- Operating profit margin increased from 3% to 9.8%

Fukusei Co., Ltd.'s main business was aquaculture and wholesale.

With the introduction of the Artlock Freezer, we have begun manufacturing and selling products for consumers in addition to our existing wholesale business.

We have successfully created high-quality rapid freezing products using the Artlock Freezer. Customer satisfaction is extremely high, and it has been ranked number one in the seafood category for two years in a row on Japan's largest online direct sales store, Tabe Choku.

By selling high-margin consumer products online and via takeout, we have successfully increased our operating profit margin from 3% to 9.8%.

Conclusion

What did you think?

When seafood processors use rapid freezer, there are various benefits such as `` expanding their business area,'' `` buying in bulk at low prices,'' and `` selling with added value.''

In fact, there are many companies that are making very large profits.

For this purpose, we recommend the Artlock Freezer, which provides high-quality freezing and has good cost performance.

In addition, we also have a document called "flash freezing Introduction Case Series - Aquaculture/Processing Edition" that introduces examples of the introduction of Artlock freezers.

[What you can learn from this material]

- Key points for success in direct sales business

- Initiatives to create high added value

- Changes before and after introducing rapid freezer

Please check the details in the document "flash freezing Introduction Case Series - Aquaculture/Processing Edition".

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Recover the machine cost in about 1 year! ]Reduce loss of tiger puffer fish with rapid freezing!](https://shunkashutou.com/wp-content/uploads/2018/07/1772bacb83f79fbd476ca3d66c8f8281_s1.jpg)

![Introducing how to freeze/thaw salmon roe and how long to store it [includes carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/09/236b884b68d07d2f5983f2b9ea66583d.jpg)

![[Explanation with photos! ] How to freeze mackerel fillets and 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/bf45f102162a8d43387d3a8d3e538034.jpg)

![Introducing how to freeze and thaw whitebait, as well as recipes for its use [Full of nutrition! ]](https://shunkashutou.com/wp-content/uploads/2023/10/04d15012ec36f91a5574f63dfa9d4771.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2016/03/99093c5fe8b0d716c39df907616e4a96.jpg)

![[How to use leftover sashimi! ] Introducing frozen preservation methods and arrangement recipes](https://shunkashutou.com/wp-content/uploads/2023/10/7451dbe2231dbc559fe002350b8add67.jpg)

![[Explanation with photos] Freezing and storage period of yellowtail fillets, carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/08/2613b1c938d382e3afc17125432167f0-1.jpg)

![[Explanation with photos! ] How to freeze saury, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/fff0f92d808aca2392b3eb576f218f08.jpg)

![[Explanation with photos] How to freeze salmon fillets, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/fb96564ba06a8cc88a72f0c971ad54e5.jpg)

![[Successful example of rapid freezing] Efforts of Yuko Fisheries Cooperative and regional revitalization by women](https://shunkashutou.com/wp-content/uploads/2015/11/68950ce21415f187d34a8a1d5b48956a.jpg)

![[For vegetable processors] What is the blanching process that improves the quality of frozen vegetables?](https://shunkashutou.com/wp-content/uploads/2016/09/ad38a1a4c704bc39303ac1864f5b0b8d.jpg)

![[Need to know] 7 points to thaw frozen crab deliciously](https://shunkashutou.com/wp-content/uploads/2023/08/394440560c05fb5b512d75b81a3fae4f.jpg)

![[8 times more nutrition! ] Introducing how to freeze clams, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/57204e2a2f115f810e29e365cfc86638.jpg)

![[Delicious frozen squid recipe! ] Tips on how to eat squid deliciously and without waste](https://shunkashutou.com/wp-content/uploads/2023/10/f3bc339b6bcaff01bd8e2aaa4257acfe.jpg)

![[Wholesale] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_oroshi_img_01.jpg)

![[Easy thawing method] Low temperature thawing to lock in the deliciousness of meat](https://shunkashutou.com/wp-content/uploads/2015/06/899e71a518bbd73569bf085ff0accd61.jpg)

![[Delicious food] Solving nursing home management issues with freezing and cooling technology](https://shunkashutou.com/wp-content/uploads/2016/05/7cabe275da8be8736f4496b952bde332.jpg)

![[Is it actually something familiar? ! ] Types of flash freezing and their temperatures](https://shunkashutou.com/wp-content/uploads/2015/07/c4fc26caaee432beead8d55028903079.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Fisheries/Fisheries Cooperative] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_suisan_img_01.jpg)

![[Explanation with photos] How to freeze octopus, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/5128a2b3fa3cc254cffab87821372215.jpg)

![[Easy installation and bulk storage] Prefabricated freezer functions and prices](https://shunkashutou.com/wp-content/uploads/2015/09/e52a1bacf6f05c6337143048f88802d7.jpg)

![[Deliver delicious ham! ] Meat processing manufacturer’s rapid freezing implementation example](https://shunkashutou.com/wp-content/uploads/2016/02/0825c4a97ac8495fd2408a91574cede6.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2016/03/661ea3ee6264fab6520017622c656870.jpg)