[Long-lasting freshness! ] Explaining the advantages and disadvantages of chilled storage and chilled transportation

In order to maintain the freshness of food for a long period of time, many people may be considering chilled storage.

Chilled storage saves food at a lower temperature just before it freezes, so the shelf life can be extended compared to refrigerated storage.

This time, we will not only introduce foods that are suitable for chilled storage and foods that are not, but also explain the advantages and disadvantages of chilled transportation.

A must-see for anyone who handles food and is considering introducing chilled storage!

目次

What is chilled?

Chilled refers to storing food by keeping its temperature around 0℃. The Japanese Agricultural Standards (JAS) specifies a temperature range of 0°C to 5°C, which is distinguished from refrigerated storage at 10°C or lower.

The key is not to freeze food, but to store it at a temperature just before freezing. The lower the temperature of the food, the better quality it will be, and is suitable for foods whose quality would deteriorate if frozen.

It is also different from partial preservation, which is slightly frozen at approximately -1℃.

Foods suitable for chilled storage

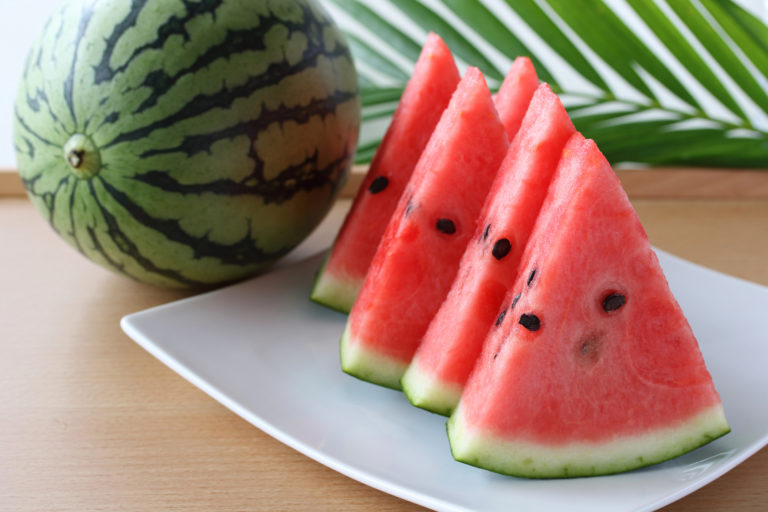

It is often used to preserve foods where freshness is important, such as fruits and vegetables, fermented foods, dairy products, and pastes.

fruits, vegetables

The lower the temperature at which fruits and vegetables are stored, the less they will deteriorate. However, when fruits and vegetables are frozen, their cells are damaged and their quality deteriorates, such as becoming shriveled after thawing.

Therefore, chilled storage, which involves storing food at a low temperature just before freezing, is very effective.

Fruits and vegetables continue to breathe even after they are harvested and separated from the body. Through respiration, plants break down stored sugars into carbon dioxide and water to extract energy.

The more you breathe, the more sugar in fruits and vegetables breaks down, leading to consumption of ingredients and deterioration of quality.

The respiration rate of fruits and vegetables decreases by one-half to one-third when the body temperature decreases by 10°C. In other words, the lower the storage temperature, the more respiration activity will be suppressed and quality deterioration will be suppressed.

In particular, seeds, young eyes, and growing leafy plants, which naturally respire at a high rate, make a big difference whether they are stored at low temperatures or at room temperature.

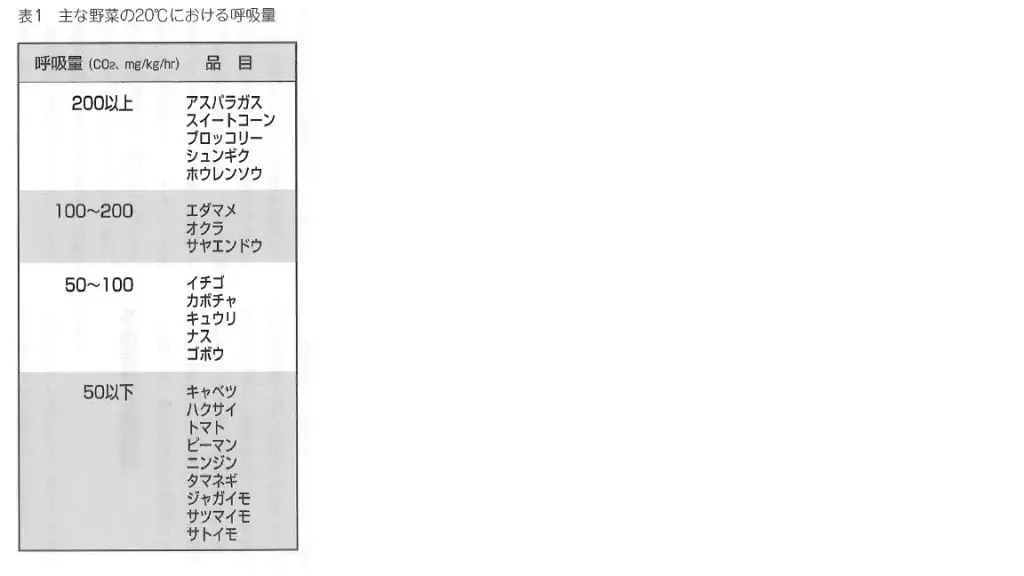

The table below shows which fruits and vegetables require a large amount of respiration. It can be seen that spinach, a leafy vegetable, and broccoli, a flower bud, have a large amount of respiration.

fermented food

Fermentation of fermented foods such as kimchi and natto can be delayed by storing them in the refrigerator, because the activity of the yeast contained in fermented foods is suppressed at low temperatures.

Therefore, long-term storage is possible.

In addition to kimchi and natto, yogurt and salted squid are also suitable for chilled storage.

paste

Nerimi such as chikuwa and kamaboko usually do not last long because they are raw, but you can extend their shelf life by storing them chilled.

If stored refrigerated, the expiry date may be within 3 days, but if stored chilled, the expiry date may be extended to one week.

Refrigerating paste will greatly extend the shelf life, but kamaboko and other foods cannot be frozen because their structure will be broken and they will have "su" (su) in them.

For pastes that cannot be frozen, it is best to store them chilled at a low temperature just before freezing.

Foods not suitable for chilled storage

Beer is not suitable for long-term storage at low temperatures as it may become cloudy. Also, foods with a lot of water may freeze, so they are not suitable.

What is chilled transportation?

Chilled distribution transportation refers to a transportation method that constantly maintains the temperature around 0℃ during transportation.

In recent years, the number of chilled foods has been rapidly increasing, as food manufacturers who prioritize quality are often switching to chilled foods for foods that were previously transported at room temperature or refrigerated.

In fact, if we look at the performance of major food wholesalers, even though their total sales are decreasing, their handling of chilled foods is increasing.

Advantages of chilled transportation

Food stays fresh for a long time

The biggest advantage of chilled distribution is that food remains fresh for a long period of time.

When vegetables are distributed through wholesale markets, the lead time from when they are shipped until they reach the consumer is 4 to 5 days.

If the food is transported at room temperature or refrigerated, even if it is fresh and delicious at the time of shipment, it will turn yellow and lose its flavor by the time it reaches the consumer.

In fact, 30% of vegetables in Japan are discarded because they are damaged or substandard during distribution.

However, if vegetables are kept at a temperature between 0℃ and 2℃, they can stay fresh for more than a week, so they can remain fresh until they reach the consumer.

This reduces waste loss during the distribution stage, leading to cost reductions.

Additionally, if the quality of the product improves through chilling, the value of the product will also increase, so we can expect price increases and sales increases.

In one example, a consumer cooperative adopted chilled transportation for vegetables, resulting in improved quality and a 17% increase in the number of items purchased.

Chilled products are more easily accepted by consumers

Another advantage is that chilled products are more easily accepted by consumers.

With the recent spread of chilled products and the popularity of chilled compartments in refrigerators, consumers have an image of chilled food as fresh and delicious.

Therefore, by selling the product chilled, it is easier to get the impression that the product is fresh.

In supermarkets, products sold frozen may be sold as ``chilled,'' or retort products may be distributed at room temperature and sold as ``chilled.''

This corresponds to the image of consumption, and is called ``reichiru'' or ``retochiru.''

Disadvantages of chilled distribution

Consistent chilled transportation must be developed

First of all, the biggest disadvantage of chilled distribution is that the effectiveness will be halved unless consistent chilled transportation from production to consumer is established.

Although it has become common for fruits and vegetables to be transported from the production area to wholesale markets by chilled transport, fruits and vegetables are still left exposed at wholesale markets.

When fruits and vegetables get warmer, their respiration rate also increases, causing them to spoil faster. For this reason, even if the producer transports the product chilled, the temperature of some varieties rises in the wholesale market and their expiration date is halved.

To avoid such problems, you need to build your own chilled distribution. This is one of the reasons why major restaurant chains are increasing their purchases directly from production areas.

By avoiding market distribution, we extend the shelf life of food products and reduce waste loss at stores, thereby reducing costs.

More expensive than normal temperature distribution

The second disadvantage of chilled distribution is that it is more expensive than normal temperature distribution. Trucks for constant-temperature transport require cooling equipment, and fuel costs are higher than usual.

However, the reason that major logistics companies' constant-temperature transportation can be used at the same price as room-temperature transportation is due to the various efforts of transportation companies.

Transportation companies are working to reduce costs, such as increasing the efficiency of transportation by having restaurants in the same area work with them, and using transportation trucks to make two deliveries in the morning and afternoon.

This type of logistics is difficult for small companies to establish, and chilled transportation can be an expensive means of transportation.

Quality retention period is shorter than frozen distribution

The third disadvantage of chilled distribution is that the quality retention period is shorter than that of frozen distribution.

Even if a product can be kept fresh for more than a month if frozen, it is often difficult to keep it fresh for a month if it is chilled.

Therefore, it may be better to freeze foods that can be frozen.

You may also consider rapid freezing, which allows for an overwhelmingly wider range of foods that can be frozen, even for foods that cannot normally be frozen.

Conclusion

What did you think. Chilling has recently become popular, but it is an innovative method to maintain the quality of foods that cannot be frozen, such as fresh foods and fermented foods, for a long period of time.

However, chilled distribution requires consistent temperature control, which increases costs.

If you are considering introducing a chilled product, it would be a good idea to consider the balance between desired quality and cost.

We also recommend comparing whether chilled or rapid freezing food is compatible with the food you are handling.

⇒⇒ Reserve a test room where you can compare chilled and rapid freezing

⇒⇒ Download detailed information about rapid freezer

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Explanation with photos! ] How to freeze pumpkin, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/36d3edf3acec7cf27351bd1211e770ac.jpg)

![Introducing the method and recipe for freezing green onions [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/negi5-768x512-1.jpg)

![Introducing how to freeze corn and recipes [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/195a6cd4120bbae043606a677c71a7dc.jpg)

![[Fruit becomes dessert! ] How to freeze kiwi and sweets recipes](https://shunkashutou.com/wp-content/uploads/2023/09/ecc0fc2bc14391ea13ce2e7a43d1416e.jpg)

![[Save onions in the freezer! ] Introducing storage methods and recipes with photos](https://shunkashutou.com/wp-content/uploads/2023/10/9d2c1259f1c42d7a0e3b61af361e5da8.jpg)

![How to freeze potatoes and a great time-saving recipe! [Moms must see! ]](https://shunkashutou.com/wp-content/uploads/2023/10/potato1-768x512-1.jpg)

![[For vegetable processors] What is the blanching process that improves the quality of frozen vegetables?](https://shunkashutou.com/wp-content/uploads/2016/09/ad38a1a4c704bc39303ac1864f5b0b8d.jpg)

![Freezing fruits (melons, grapes, pineapples) [rapid freezing demo]](https://shunkashutou.com/wp-content/uploads/2017/04/f6c25534c570755c38676fba88215298.webp)

![[Explanation with photos! ] How to freeze saury, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/fff0f92d808aca2392b3eb576f218f08.jpg)

![[Import/Export Industry] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_yunyu_img_01.jpg)

![How to freeze tomatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/tomato-768x513-1.jpg)

![[Tips for making egg rolls that can be frozen] Introducing freezing methods, storage periods, and recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/tamagoyaki-768x512-1.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Is it actually something familiar? ! ] Types of flash freezing and their temperatures](https://shunkashutou.com/wp-content/uploads/2024/10/c4fc26caaee432beead8d55028903079.webp)

![Introducing how to freeze mushrooms and recipes [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/a4b193bf883e378a4d3fb316b2edaf43.jpg)

![Freezing garlic, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/30693b4b122ff6c57afff367b35bc861.jpg)

![How to freeze cucumbers and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/37a83e91a989dfbc285ac11dede7c8c2.jpg)

![How to freeze and thaw chestnuts, storage period, and 5 recipes! [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/c590a9e6fb16ed45fe2fdd32813de03b.jpg)

![Introducing how to freeze ginger and recipes [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/myoga4-624x432-1.jpg)

![[Explanation with photos] How to freeze winter melon, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/8c301e3fcfbb9c7f457d8b05dfea902d.jpg)

![[Explanation with photos! ] How to freeze and fry croquettes, 5 carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/09/b364ee97a71777f9dd2e35fddbbdda72.jpg)

![[Nutrition remains the same! ? ] Introducing how to use frozen vegetables and recommended recipes](https://shunkashutou.com/wp-content/uploads/2023/10/vegetables-reito-1-1-768x511-1.jpg)

![[Fisheries/Fisheries Cooperative] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_suisan_img_01.jpg)

![Introducing recipes and methods for freezing spinach [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/spinachh-768x512-1.jpg)

![[Distribute high quality mangoes! ] New frozen processing of mangoes using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/08/4e9ff0df5721aa6f8fbdfae6d56ad787.webp)