A complete explanation of rapid freezer! Explanation of benefits, examples, and advantageous subsidy information

" rapid freezer "are attracting attention as a new freezing technology, especially in the food industry.

This method has the advantage of allowing food to be frozen with almost no loss in quality and stored for long periods of time, and is therefore being introduced in a variety of food-related businesses.

On this page, we will introduce everything you need to know about rapid freezer rapid freezer the different types, how to choose one, and prices.

Please read until the end, as we will also introduce you to a cost-effective introduction method using subsidies.

目次

- 1What is rapid freezer (flash freezer/shock freezer)?

- 2What are the benefits of introducing rapid freezer?

- 3What kind of freezing principle does rapid freezer have?

- 4How to choose rapid freezer

- 5What is the price of rapid freezer?

- 6 rapid freezer last?

- 7Subsidies are recommended if you are considering installing rapid freezer!

- 8We also recommend leasing or renting rapid freezer (operating leases)!

- 9 Summary

What is rapid freezer (flash freezer/shock freezer)?

Naturally, a "rapid freezer" refers to a "mechanical device that can perform rapid freezing."

There are multiple ways to express it, and there are various names such as ` rapid freezer'', `` rapid freezing'', ``flash freezing machine'', ``flash freezing machine'', ``instant freezer'', and ``shock freezer'', but none of them are. They refer to almost the same thing. Also, it is basically used for business purposes.

So what does "rapid freezing" mean?

First of all, freezing generally refers to freezing food and keeping it at -18℃ or below. On the other hand, rapid freezing refers to the freezing method described below.

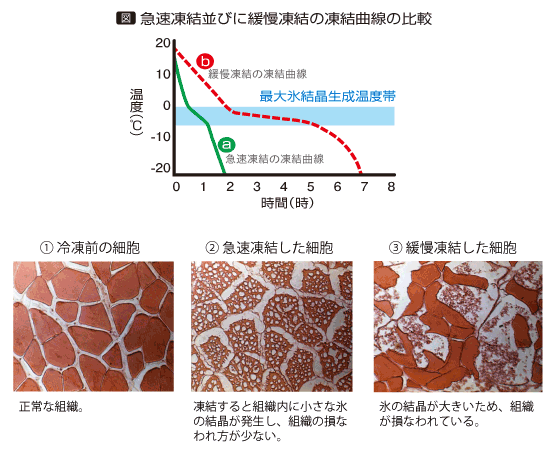

Although it is not a strictly defined term, "rapid freezing" generally refers to a method of freezing so that the temperature passes through the maximum ice crystal formation zone (-1℃ to -5℃) within 30 minutes. Masu.

If food is frozen in a way that does not quickly pass through the "zone of maximum ice crystal formation," as is the case with normal freezing (slow freezing), the "phenomenon of ice crystals rupturing cell membranes" will occur, significantly reducing the quality, flavor, and texture of the food.

In contrast, when food is frozen quickly through the "maximum ice crystal formation zone," as in the case of rapid freezing (flash freezing), the "phenomenon of ice crystals rupturing cell membranes" does not occur, and the quality, flavor, and texture of the food can be maintained.

In other words, in theory, high-quality freezing can be achieved by freezing the material so that it passes through the maximum ice crystal formation zone (-1°C to -5°C) as quickly as possible.

This is called `` rapid freezing'', and the mechanical devices that can do this are `` rapid freezer'', ``quick freezing machine'', ``quick freezer'', ``flash freezing machine'', ``flash rapid freezing machine'', ``flash freezer'', and ``shock freezer''. ” and so on.

Recently, rapid freezer of household refrigerators has become more powerful, but commercial rapid freezer have a much higher cooling capacity than household ones, so the freezing speed is completely different. As a result, the quality is also orders of magnitude better.

Nowadays, thanks to improvements in the technical capabilities of each rapid freezer manufacturer, high-quality products such as fresh fish, meat, vegetables, fruits, sashimi, sushi, soba, udon, ramen, and curry, as well as bread, Japanese sweets, and fried foods, are now available. It is now possible to freeze.

rapid freezer have come to be used in a variety of situations in the food industry because they can freeze all types of food to high quality. rapid freezer capable of rapid freezing have become a new standard for commercial frozen food manufacturing and freezing methods.

What are the benefits of introducing rapid freezer?

rapid freezer are used in a variety of situations in the food industry, but what are their actual benefits?

Here, we would like to introduce the benefits of introducing this system using several case studies.

Increase sales

rapid freezer are often introduced for the purpose of increasing sales.

~Issues related to sales that we would like to solve with rapid freezer as asked by customers~

- I want to expand my sales channels to mail order and distant areas.

- I want to open multiple stores with a central kitchen.

- I want to eliminate losses due to expiration dates and quality deterioration.

By using rapid freezer, it is possible to freeze a variety of items without compromising their quality, including fresh fish, meat, vegetables, fruit, sashimi, sushi, soba, udon, ramen, curry, bread, Japanese sweets, and fried foods.

If you are a producer or processor of meat, fish, vegetables, or fruits, you can preserve and distribute your products without worrying about expiration dates or quality deterioration.

For this reason, there are many cases in which rapid freezer are used to sell products to distant locations such as overseas. We also have many customers who sell directly to consumers via mail order.

If you are a restaurant owner, you can rapid freezing the products that you normally serve in your store and sell them as frozen foods through mail order, etc.

By rapid freezing freshly made products, they can be served with almost no loss in quality, such as taste or flavor, even after thawing.

Furthermore, by utilizing a central kitchen, products can be produced and frozen in bulk, making it possible to expand to multiple stores without increasing the number of chefs.

In addition, by using rapid freezer, it is possible to preserve food without worrying about expiration dates or deterioration in quality.

This allows items that would otherwise have been thrown away (waste loss) to be sold as products, which can lead to increased sales and improved profit margins.

Quality improvement

~Issues related to quality improvement that customers would like to solve with rapid freezer ~

- I want to distribute while maintaining freshness.

- Want to prevent quality deterioration during distribution and processing processes

It may seem obvious, but the longer fresh food sits, the more its taste, flavor, and freshness will deteriorate.

Therefore, when handling raw ingredients, quality deterioration occurs from the moment they are distributed. A major advantage of rapid freezer is that they can maintain the taste, flavor, and freshness of raw ingredients.

It will be possible to transport ingredients in a high-quality, almost fresh state to remote areas where it would take a long time to deliver them.

In addition, fresh fish and other products have the issue that their freshness easily deteriorates when they are processed, so they are often distributed as whole fish without processing. In such cases, the use of rapid freezer can stop the deterioration of quality and allow distribution.

With the latest freezing technology, processed foods can be rapid freezing, making it possible to distribute them while maintaining their quality and shape.

Improving efficiency of manufacturing and cooking operations

~Issues related to sales that we would like to solve with rapid freezer as asked by customers~

- I want to expand my sales channels to mail order and distant areas.

- I want to open multiple stores with a central kitchen.

- I want to eliminate losses due to expiration dates and quality deterioration.

rapid freezer not only enable long-term storage of food without compromising its quality, but also help improve manufacturing and cooking processes.

For seasonal items such as New Year's dishes and Christmas limited edition products, production is concentrated at certain times of the year. Naturally, the gap between the busy season and the slow season becomes large, which puts a strain on employees.

With rapid freezer, the quality can be maintained even a year after production. Therefore, it is possible to realize planned production even for products that need to be produced in large quantities only during busy periods.

It can also be used for pre-cooking for the same reasons.

By cooking everything from preparation to the final product in one go and then freezing it in rapid freezer, it is possible to streamline the effort and process from order to serving. This allows operations to be run with a small number of people, and anyone, even without experience, can easily cook and serve the food.

The same can be said for the case of a central kitchen system, and there are cases where multiple stores can be operated without chefs by consolidating production. By manufacturing products in bulk, it is easy to reduce material costs and labor costs.

It also simplifies work within the store, allowing even people with no skills to run the operations.

What kind of freezing principle does rapid freezer have?

There are several types of rapid freezer that can freeze a variety of items to high quality, and each manufacturer has a different freezing principle (cooling mechanism). Each type is compatible with different foods and has different strengths in freezing technology, so when introducing a flash freezer, it is important to determine the model that is best suited for your company's products.

In this chapter, we will introduce five types of freezing principles of typical rapid freezer.

Air blast type (air freezing)

This is the most popular freezing method. It works by blowing cold air onto the food, removing heat from the food and freezing it.

Since this works in the same way as a regular freezer, many people think that it does not achieve rapid freezing, but by "speeding up the heat exchange rate by applying a special airflow method, and efficiently removing heat" and "lowering the temperature inside the freezer," it is possible to achieve rapid freezing freezing at a speed that is completely different from conventional freezing.

The temperature inside a freezer varies depending on the model, but most are -35°C. However, in order to rapid freezing (= remove heat quickly), factors other than temperature must be taken into consideration.

The lower the temperature, the better, but the air must be blown according to the characteristics and shape of the food.

【merit】

Since food is frozen by blowing cold air onto it, it is possible to freeze products in any state, such as vacuum-packed, frozen in a tray, or without any food packaging.

It is characterized by being extremely easy to use, hassle-free, and extremely user-friendly.

In addition, by freezing the ingredients in their naked form, their appearance can be maintained, resulting in a more attractive looking product.

【Demerit】

Depending on the type of rapid freezer, the food may dry out because the air is blown directly onto the product. Therefore, it is necessary to carefully consider the model of rapid freezer depending on the product to be frozen.

In addition, some products require defrosting, which makes continuous operation difficult and may result in shorter operating times.

(Example: 2 to 3 hours of freezing operation → 1 hour of rest for defrosting → 2 to 3 hours of freezing operation repeated)

[Recommended models]

We recommend the Art Lock Freezer (manufacturer: Daybreak Co., Ltd.).

Art Lock freezers are equipped with a micro-wind system, which has the advantage of preventing food from drying out and allowing for fast freezing. In addition, the anti-frost mechanism prevents frosting and allows for continuous operation for up to 72 hours. Therefore, one of the major advantages of Art Lock freezers is their high production efficiency, as they do not require the time required to stop production for defrosting, which is a disadvantage of air blast freezers.

In addition, because it has the ability to freeze products at any temperature, it is also possible to freeze hot, freshly made products. For example, freshly fried tempura, fried chicken, and pizza straight out of the oven can be placed in the freezer and frozen without being cooled down.

Food tastes best when it's freshly made, so being able to freeze it quickly while maintaining its quality at that moment means that it can retain that freshly made deliciousness even after thawing.

Liquid type (liquid freezing)

Liquid-type rapid freezer freeze food by immersing it in antifreeze such as alcohol, which is cooled to -10℃ to -35℃. Food must be vacuum-packed to prevent unfreezable liquids such as alcohol from adhering to the food. Due to its high thermal conductivity, it has the advantage of high cooling efficiency and fast freezing speed.

【merit】

Freezing speed is faster than air blast type.

(e.g., 25 minutes for air blast type, 18 minutes for liquid type)

It works well with thick ingredients (such as blocks of meat) and allows for quick freezing.

【Demerit】

Vacuum packaging is necessary because the ingredients are soaked in alcohol. Therefore, it is not suitable for products that are difficult to vacuum package (such as cakes that will get crushed) or products that will deteriorate when vacuum packaged.

It requires a lot of work, such as vacuum packaging, careful topping up and handling the alcohol, checking to make sure the corners of the ingredients haven't punctured the vacuum bag, and wiping off the alcohol after freezing.

[Recommended models]

We recommend the Rejoice freezer.

Among liquid types, this product offers excellent cost performance and is easy to use.

There is a wide range of sizes available, from small ones that run on 100V power, so you can choose the size of freezer that best suits you.

Contact type (contact freezing)

It is also known as plate freezing.

Sometimes called a contact freezer, this method rapidly freezes food by placing it directly on the cooling surface.

The cooling section is a metal plate called a flat tank, inside which flows a refrigerant at -30℃ to -40℃.

It is said to be very efficient at cooling because the chilled metal comes into direct contact with the food.

【merit】

Since it is a direct contact process, it is also possible to apply pressure at the same time and shape ingredients to a specific height.

For this reason, it is often used in the mass production of meat, paste, etc.

【Demerit】

Since the flat tank comes into direct contact with the product, it is limited to products that are packaged in the same way as liquid types.

In addition, since contact freezers remove heat by having the flat tank come into contact with the food, freezing will be slower if the product packaging contains a lot of air or if the product does not adhere tightly to the flat tank when pressurized.

liquefied gas type

Although not very common, this method uses liquefied gases such as liquefied nitrogen or liquefied carbon dioxide to freeze the food.

Liquefied carbon dioxide can be applied to food at -78.5℃, while liquefied nitrogen can be applied to food at -196℃. This allows for high-quality freezing.

【merit】

Because it uses liquefied gas, there is no need for a refrigerant or heat exchanger to cool the interior of the cabinet.

As rapid freezer, its structure is simple and maintenance is relatively easy.

【Demerit】

Liquid nitrogen and liquefied carbon dioxide must be used, and care must be taken when handling them.

There are also risks, such as oxygen deprivation due to gas filling up the space and the risk of fire and explosion.

Another feature is that since liquid nitrogen or liquefied carbon dioxide must be used, the running costs are relatively high compared to alcohol freezing and air freezing.

Special method type

There is a type of rapid freezer that does not belong to any of the above categories. On this page, we refer to it as a "special type."

A typical example is a system that uses magnetic flux, electromagnetic waves, magnetic fields, vibrations, etc. to "put water molecules into the optimum state for freezing."

In theory, this mechanism makes it possible to freeze cells without destroying them.

【merit】

Theoretically, it is possible to freeze food without destroying the cells, which may improve the quality.

However, there may be differences in quality while there may not be, so if you are considering purchasing one, it is recommended that you check with a freezing test.

【Demerit】

Compared to the freezing mechanism, the cost tends to be higher because it is equipped with a "mechanism that puts water molecules in the optimal state for freezing." As such, there are multiple freezing principles in rapid freezer, and their features vary greatly.

So how do you choose rapid freezer?

In the next chapter, we will introduce how to choose rapid freezer.

How to choose rapid freezer

From here, we will introduce how to choose rapid freezer.

Of course, the selection of rapid freezer is very important. There are many people who say that they should have purchased a different model after purchasing it, so choose carefully.

When choosing rapid freezer, it is important to consider the food to be frozen and the operation, and to choose the size based on the amount of frozen processing, not the internal capacity.

I will explain each one.

Select the freezing principle that best suits the food to be frozen and the operation

When choosing rapid freezer it is particularly important to consider the compatibility of the freezing principle with the ingredients to be frozen and the operation.

This compatibility greatly affects product quality and productivity.

“What characteristics do frozen foods have?”

“In what conditions should you freeze ingredients?”

“Should I package before or after freezing?”

“What is the process from rapid freezing to storage in the freezer?”

“How much and how long should I store it in the freezer?”

Make your selection after considering these factors to some extent.

-Types of freezing principles

・Size of rapid freezer

- Cart-in type, which freezes the entire cart, and tray-in type, which inserts and removes trays with food items on them.

The selection of rapid freezer will make a big difference.

If you have not yet decided on the ingredients to be frozen or the operation, or if you are installing rapid freezer for the first time, we recommend that you check with a professional.

Choose the size based on the amount of freezing that can be done, not the amount of storage space.

Usually, the size of a refrigerator or freezer is determined by its capacity (how many liters).

However, the biggest reason for choosing the size of rapid freezer is to "determine the size based on the capacity of the machine."

Here are some examples of common mistakes that actually happen:

ーーーーーーーーーーーーーーーーーーーーーー

・Actual failure examples

In a freezing test, three fish fillets were frozen in 30 minutes.

We found that if we filled the cabinet with this fish fillets, it would hold 15kg.

I chose the model based on the assumption that it could freeze 30 kg per hour (15 kg x 2 rotations for 30 minutes).

When I actually put 15 kg in the freezer and froze it, it took 2 hours to freeze and only 1/4 of it was frozen as expected.

ーーーーーーーーーーーーーーーーーーーーーー

The number one cause of this failure is insufficient power of the refrigerator.

rapid freezer has a part called a refrigerator, which is the engine of the machine, and how much it can freeze (how much heat energy it can take from the product) varies greatly depending on the power of this refrigerator.

If you put more food into the freezer than the freezer can cool, the freezer will not be able to keep up and the temperature inside will rise. As a result, the freezing speed will slow down, and you may end up with problems such as "you can't freeze the amount you expected" or "the quality will be worse than expected."

For this reason, it is important to select rapid freezer based on the freezing capacity (amount of freezing per hour).

The freezing process varies depending on the moisture content and ingredients of the ingredients, so be sure to check with the manufacturer to determine the amount of freezing required for the ingredients you are actually freezing.

So far, we have introduced how to choose rapid freezer.

Selecting rapid freezer may seem easy, but because it requires a wide range of knowledge, selecting the most suitable rapid freezer is actually quite difficult.

Therefore, it is very important to communicate the product to be frozen and the purpose to the rapid freezing manufacturer, conduct a freezing test, and decide which principle to choose.

What is the price of rapid freezer?

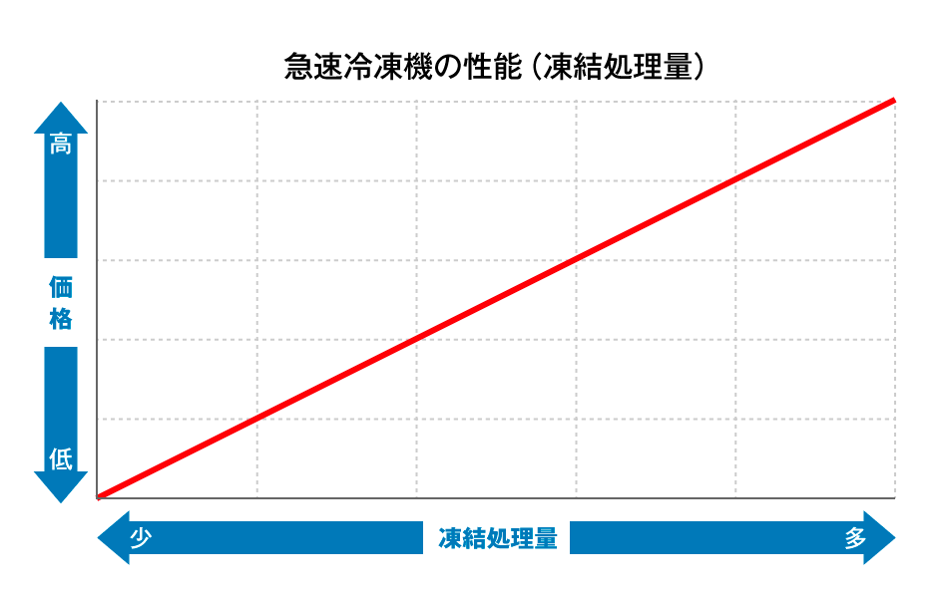

The price of rapid freezer varies depending on the product characteristics and freezing principle.

In general, the price increases or decreases in proportion to the amount of freezing that can be done (amount frozen per hour).

What is commonly referred to as a "rapid freezer" starts at 2 million yen for the smallest model, and the higher the performance, the higher the price.

In addition, although the performance and freezing quality are inferior, there are an increasing number of small rapid freezer can be introduced for prices starting from several hundred thousand yen, so it is best to consider introducing one after looking at the price and performance.

In addition, transportation and installation costs may vary depending on the installation area, floor, and delivery conditions, so if you want to calculate an accurate cost, it is recommended that you clearly state your conditions when inquiring.

rapid freezer last?

As mentioned above, rapid freezer are by no means cheap.

Therefore, many people are probably wondering how long the equipment can be used for.

The statutory useful life of rapid freezer as stipulated by the National Tax Agency is 6 years for kitchen equipment and 10 years for production equipment. However, the statutory useful life does not necessarily mean the lifespan.

In reality, flash freezers are often used for longer than the statutory useful life, with rapid freezer being used on a regular basis for more than 10 years, and in some cases for more than 20 years.

This product can be used for more than 10 years, although this depends on how it is used on-site and how it is maintained and maintained.

Subsidies are recommended if you are considering installing rapid freezer!

As mentioned above, rapid freezer can be used for more than 10 years, making them extremely cost-effective.

While some customers choose to implement the system as is, many also take advantage of tax incentives and subsidies to make it easier to achieve cost-effectiveness.

Among the many subsidies and grant programs, the most commonly used are the "Manufacturing Subsidy" and the "Business Restructuring Subsidy" (as of 2023). Both are available to small and medium-sized enterprises, and the subsidy amounts have high limits -1 million to 40 million yen for the "Manufacturing Subsidy" and 1 million to 100 million yen for the "Business Restructuring Subsidy" - making it possible for businesses of various sizes to receive subsidies.

There are also many other examples of implementation using subsidies from prefectures, cities, towns, and villages.

For more information, please feel free to contact our dedicated staff.

In addition, if you use a consulting company affiliated with Daybreak, we will provide support for the creation of time-consuming documents and reports after the grant is selected.

We can solve all your worries about subsidies, such as those who want to just give up on subsidy documentation because it's a hassle, or those who are applying for a subsidy for the first time and don't know what to do.

We also recommend leasing or renting rapid freezer (operating leases)!

We have provided information about subsidies above, but in the case of large companies, they are often not eligible for subsidies and are therefore often unable to use them.

I also hear that some people are reluctant to use subsidies because they require time for document preparation, as well as reporting requirements after the grant is approved.

You want to keep costs down and avoid the hassle, but the price is too high to implement... In such cases, leasing or rental (operating lease) is recommended.

It is possible to use rapid freezer while keeping the initial cost of installation significantly low. By taking advantage of leasing and rental systems, you can use it for as little as a few tens of thousands of yen per month, greatly lowering the barrier to installation.

Conclusion

On this page, we have introduced the overall picture of rapid freezer.

When selecting rapid freezing, it is necessary to compare and choose one that takes into account compatibility with the ingredients and operation. When you actually start considering it, we recommend that you first test the ingredients and select the equipment.

You can try out various types of rapid freezer below. Please feel free to contact us. We also conduct online tests.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2024/08/09c17e4deeb1ac0cdc5a513eaf89ab1a.webp)

![[Explanation of how to fry! ] How to freeze and thaw pork cutlet, remake recipe!](https://shunkashutou.com/wp-content/uploads/2023/10/0a4143ad8ea0cc6bb6fdab8c74fab407.jpg)

![[Explanation with photos! ] How to freeze and fry croquettes, 5 carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/09/b364ee97a71777f9dd2e35fddbbdda72.jpg)

![Explaining how to freeze garland chrysanthemums with photos! [Defrosting and storage period, 5 recipes]](https://shunkashutou.com/wp-content/uploads/2023/10/syungiku-catch-768x512-1.jpg)

![How to freeze potatoes and a great time-saving recipe! [Moms must see! ]](https://shunkashutou.com/wp-content/uploads/2023/10/potato1-768x512-1.jpg)

![[Rapid freezers in 2021] Market Trends and Customer Success Stories](https://shunkashutou.com/wp-content/uploads/2020/12/7F9A9CB9-A494-4E6A-946E-079279C596E6.jpeg)

![[Nutrition remains the same! ? ] Introducing how to use frozen vegetables and recommended recipes](https://shunkashutou.com/wp-content/uploads/2023/10/vegetables-reito-1-1-768x511-1.jpg)

![[Can it be frozen? ] 5 recipes for yogurt freezing and shelf life!](https://shunkashutou.com/wp-content/uploads/2023/10/yogurt-catch-768x512-1.jpg)

![Introducing the method and recipe for freezing green onions [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/negi5-768x512-1.jpg)

![[Secret Technique] Introducing the freezing preservation and remake recipe of Kinpira Burdock!](https://shunkashutou.com/wp-content/uploads/2023/09/4c4b704274331befeed83cc4493acb75-1.jpg)

![[Can it be frozen? ] How to freeze and thaw okonomiyaki, arrangement recipe!](https://shunkashutou.com/wp-content/uploads/2024/01/58bc763c02f23a2a6442d6449853a67b.jpg)

![How to freeze natto, expiration date, baby food and carefully selected recipes [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/055e5e865986b68d11c3f49f11ea6008.jpg)

![[Fruit becomes dessert! ] How to freeze kiwi and sweets recipes](https://shunkashutou.com/wp-content/uploads/2023/09/ecc0fc2bc14391ea13ce2e7a43d1416e.jpg)

![[Freshly made raw soba all over the country! ] Example of introducing a quick freezer at a soba restaurant](https://shunkashutou.com/wp-content/uploads/2024/09/6d8138adcf26c410c11b25d5b8d2f3de.webp)

![[For maintaining food quality!] Three functions you should know about constant temperature and high humidity storage](https://shunkashutou.com/wp-content/uploads/2015/10/krefrigerator.jpg)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/07/2a0deb9a6db53165f0a4938bc80cee46.webp)

![[For the lunch box manufacturing industry] Business issues can be solved by using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/04/f93f171f5d29bdb15c4b8d06e244b002.jpg)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[For food manufacturers] What is the meaning of IQF freezing and what is rapid freezer required for it?](https://shunkashutou.com/wp-content/uploads/2017/03/40008d9f1a752dd006399fe1c4beda34.jpg)

![[Dramatically extends the shelf life of vegetables! ] What is blanching process?](https://shunkashutou.com/wp-content/uploads/2023/07/8fce721a563a0e86a740b4d11dc63766.jpg)

![[Explanation with photos! ] How to freeze beef, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/8717f2a867f52157bab47841b0f29019.jpg)

![Introducing the frozen preservation method and recipe for bamboo shoots [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/4c47b443710cb5788386ab6fd1fa0a07.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Explanation with photos! ] How to freeze pumpkin, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/36d3edf3acec7cf27351bd1211e770ac.jpg)

![Freezing fruits (melons, grapes, pineapples) [rapid freezing demo]](https://shunkashutou.com/wp-content/uploads/2017/04/f6c25534c570755c38676fba88215298.webp)

![How to freeze zucchini and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/zucchini6-768x512-1.jpg)

![[Can it be frozen? ] Introducing a good way to freeze green peppers and side dish recipes](https://shunkashutou.com/wp-content/uploads/2023/09/30407f106c5c082468c66af0d40c5858.jpg)

![[Explanation with photos! ] How to freeze taro, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/116858380_-768x512-1.jpg)

![[Can it be frozen? ] Introducing the recipe and how to freeze potato salad!](https://shunkashutou.com/wp-content/uploads/2023/10/3c640cd23d65764c14f701d25970ed59.jpg)

![How to freeze parsley, nutrition, and 5 easy recipes! [Solved with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/paseri-768x513-1.jpg)

![How to freeze sweet potatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/36256af24531b73a036523ba73bdf9ec.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![[Labor shortage]The benefits with examples of using rapid freezer](https://shunkashutou.com/wp-content/uploads/2019/04/hitodebusoku-article-main_pc.jpg)

![[Food/processing manufacturers] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_kakou_img_01.jpg)

![[Freezing Neapolitan] rapid freezing demonstration](https://shunkashutou.com/wp-content/uploads/2016/09/napolitan.jpg)

![[Eliminating the labor shortage! ] Introducing the benefits of the cook-freeze system!](https://shunkashutou.com/wp-content/uploads/2018/12/72352e99f79e7f2bfa6e9eca24acceb0.webp)

![How to freeze celery, nutrition, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/serori-768x512-1.jpg)

![Introducing recipes and methods for freezing and thawing bananas [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/494e7567627fb35e47ee5cb0e06e142c.jpg)