Specifications and standards for frozen food - Understanding the requirements when using rapid and flash freezers

Even among food manufacturers, there are many who do not know what is required for frozen food when it comes to specifications and standards.

In recent times, refrigeration technology has evolved significantly and frozen food is now as good as, or even better than, refrigerated foods.

As a result, it has opened a new door of opportunities to expanding sales channels, increasing sales, and maintaining quality standards over longer durations.

In this article, we will define frozen foods, their specifications and standards, the conditions necessary for manufacturing and sales, and the reasons why rapid and flash freezing are necessary.

目次

- 1What is frozen food?

- 2Examples of frozen food businesses

- 3Can frozen foods be sold by individuals?

- 4Specifications and standards for frozen foods stipulated by the Food Sanitation Act (specific to Japan)

- 5Required conditions for manufacturing and selling frozen foods (quality labeling and business license)

- 6Rapid and flash freezers for selling and increasing sales of frozen foods

- 7 Conclusion

What is frozen food?

Frozen foods have become commonplace these days, but did you know that there is a fixed definition for frozen foods?

Foods that meet the following four criteria are considered frozen foods. If you are considering selling food products yourself, be sure to check the criteria thoroughly.

Processed before freezing

You need to select fresh ingredients and prepare them. For fried fish for example, there are processes such as removing inedible parts such as the head, bones, and internal organs, portioning it into three pieces, cutting it into fillets, adding breadcrumbs, etc., and then simply frying it.

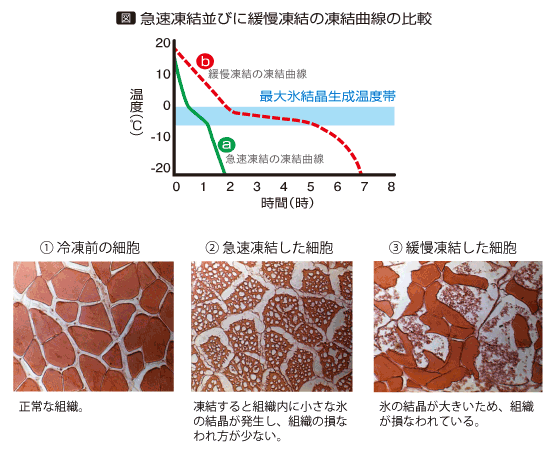

Rapid freezing

If you freeze products using standard freezing methods, the cells of the product will be damaged, leading to quality deterioration.

By using a special freezing method called rapid or flash freezing, which rapidly lowers the temperature and freezes the food in a short period of time, it becomes as close to its quality before being frozen as possible.

Appropriate packaging

Appropriate packaging is used to prevent quality deterioration from the time the food is produced until it reaches the consumer.

Examples include vacuum packaging to prevent food from oxidizing, and packaging in metal cans, which is mainly used for canned food. In addition, you need to clearly display all the information related to your food on the packaging.

Storage below -18℃

Frozen food from production to sales is maintained at -18℃. This keeps freezer burns to a minimum.

Frozen foods achieve high quality by meeting this definition. All frozen foods sold around the world (restaurants, online, supermarkets, other shops, stores, etc.) are sold based on these criteria.

Examples of frozen food businesses

There are various industries and types of businesses that sell frozen foods.

Online stores

There are many online stores that sell frozen foods.

As inventory is managed online, products are often sold frozen rather than refrigerated, regardless of the product.

Supermarkets

Most commonly, frozen foods are sold at supermarkets.

In the case of supermarkets, there are many cases where frozen foods purchased from frozen food manufacturers such as Nichirei are sold through agencies or intermediaries.

Restaurants

Meals served at restaurants are often kept frozen.

There are many restaurants that defrost frozen food in the refrigerator before serving, or heat it and sell it as is.

Other facilities

Frozen foods are also provided to nursing homes, hospitals, school cafeterias, and other facilities.

In most facilities, food is stored in refrigerated or chilled storage, but there are also many cases in which food is stored frozen.

Can frozen foods be sold by individuals?

When it comes to selling frozen foods, there is a perception that only companies and corporate organizations can sell them, but is it possible for individuals to sell them as well?

Yes, it is possible to sell frozen food as an independent individual.

Qualification required for indepedent sales

For the Japanese market, to sell frozen foods, a business license based on the Food Sanitation Law and a qualification as a food hygiene manager are required. Without these qualifications, you cannot sell frozen foods. In addition, even if you have already obtained a business license or other qualification in the food manufacturing industry, you will need to apply for a new application in order to sell frozen foods that you have manufactured yourself or as an individual. In order to obtain the necessary permits and qualifications, you must have the necessary equipment, follow prescribed procedures, and attend training sessions.

Therefore, in order to sell frozen foods as an individual, you will need various qualifications, completion of required procedures, and participation in seminars.

Specifications and standards for frozen foods stipulated by the Food Sanitation Act (specific to Japan)

Frozen food classification(for Japan only)

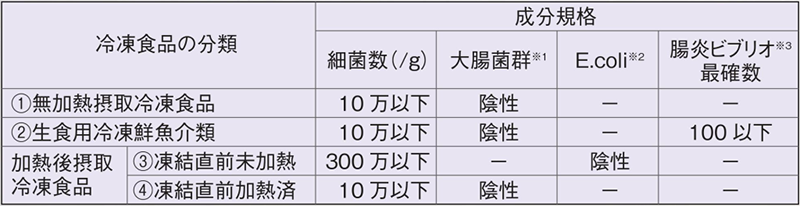

Standards for frozen foods are determined by the Food Sanitation Act.

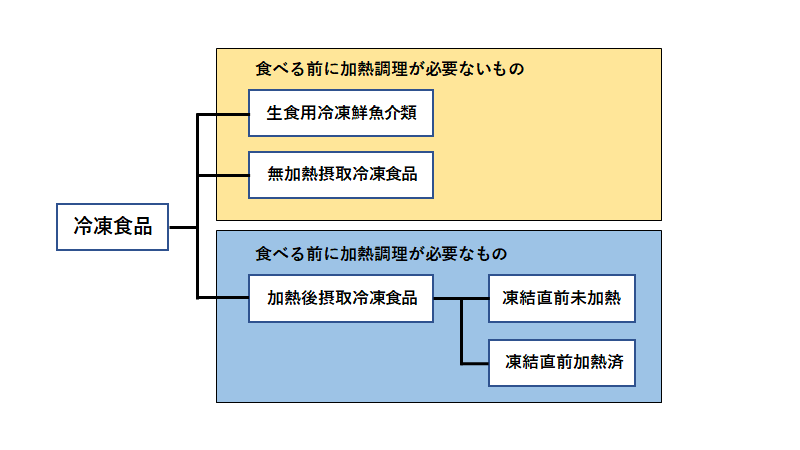

There are four types of frozen foods according to the standards.

Foods are classified according to whether they require cooking before eating, and those that do not require cooking before eating are further divided into frozen fresh seafood for raw consumption and frozen foods for consumption without cooking.

Foods that require cooking before eating are called frozen foods that are eaten after cooking, and are further classified by whether they are cooked before freezing.

・Frozen fresh seafood for raw consumption

Frozen fillets, shelled seafood, etc. that are eaten raw. Examples include frozen sashimi and sushi.

・Frozen foods for consumption without cooking

Manufactured or processed food that does not require any cooking before eating. Examples include fruits, cakes, and frozen foods that can be packed in lunch boxes.

・Frozen foods that are eaten after cooking

Foods that require cooking before eating.

Frozen foods that are consumed after cooking are further divided into cooked food just before freezing and uncooked food just before freezing, based on whether the food is cooked or not before being frozen.

Examples include fried potatoes, frozen gyoza, and fried chicken. Most of what is generally called frozen food is frozen food that is consumed after cooking.

*There are some exceptions depending on the food.

Frozen food ingredient standards and testing methods (for Japan only)

There are four criteria for the composition of frozen foods stipulated by the Food Sanitation Act in Japan: bacterial count, coliform bacteria, E. coli, and Vibrio parahaemolyticus.

These four bacteria can cause food poisoning if ingested.

Therefore, we looked into tests that use indicators such as the number of bacteria to check whether there is any harm to the human body.

The required tests and standards for frozen foods differ depending on the classification defined in the standards.

The required exams among the four above must be taken and each criterion must be met. Test standards also differ depending on the classification.

Frozen food processing standards

Among frozen foods, seven processing standards have been established only for frozen fresh seafood for raw consumption.

The main requirements are to use fresh seafood as raw ingredients, to process in hygienic locations and processes, and to freeze immediately after processing.

Required conditions for manufacturing and selling frozen foods (quality labeling and business license)

To manufacture and sell frozen foods, there are two requirements: food quality labeling and obtaining a business license.

The specific contents of quality labeling and business license are explained below.

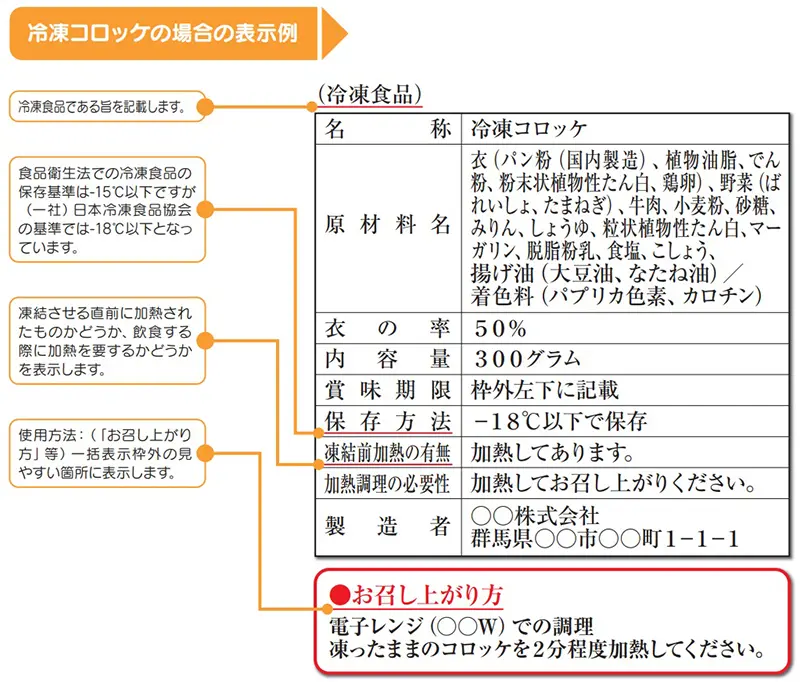

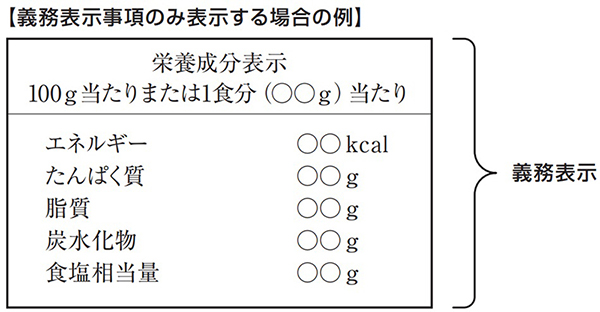

Quality labeling for frozen food sales (common to all industries) - for Japan only

A new food labeling law called the Food Labeling Law came into effect in April 2015. It regulates labeling specifications and is in place to add another layer of protection for the consumer.

The items required for quality labeling of frozen foods as stipulated by the Food Labeling Act are as follows.

Items required for frozen foods

1. Must be frozen food

2. Food name

3. Ingredients

4. Additives

5. Contents

6. Deadline display

7. Storage method

8. Does the product need cooking

9. Cooking instructions

10. Manufacturer or processor

11. Address of manufacturing or processing plant

12. Nutrition information display

Among frozen foods, quality labeling standards are set individually for foods that are specified by the JAS Act in Japan.

Specifically, there are two types: frozen cooked foods such as frozen dumplings, frozen spring rolls, and frozen fries, and frozen vegetables such as broccoli and spinach. For cooked frozen foods and vegetables, you need to check which items apply and what items are required.

Business license required for selling frozen foods (standards vary depending on industry) - for Japan only

If you are handling food, you must meet the standards set by your industry and obtain a business license. Even if you handle food, if you are starting a new frozen food business, you will need a new food freezing or refrigeration business license. Please note that you cannot sell frozen foods if you do not have a business license. It is a good idea to check the website of the Japanese Ministry of Health, Labor and Welfare.

Applications for business permits are made at the public health center in each prefecture in Japan.

The conditions required to obtain a business license from a public health center are as follows:

・Human resources requirements

・Equipment requirements

・Common standards

・Specific criteria

・Human resources requirements

When operating a business that handles food, each facility must have at least one food sanitation officer.

The food hygiene manager has the role of managing and operating food to prevent food poisoning and to uphold food sanitation laws.

To become a food sanitation supervisor, you must either attend a food sanitation supervisor training course or have specific qualifications.

If you meet the above conditions, you can apply to become a food hygiene supervisor.

・Conditions regarding equipment (common standards)

Common standards are the rules and standards required for all industries (not including vending machines)

Important indicators include the structure of the facility where you operate, food handling equipment, and water supply status.

・Conditions regarding equipment (specific standards)

Specific standards are the standards established and specific to different industries.

Specific standards for food freezing or refrigeration industry include processing rooms, freezing rooms, and cold storage rooms, which must be separated, and thermometers must be installed in the freezing and cold storage rooms.

The standards for equipment required to obtain a business license are determined by each prefecture in Japan, so regulations vary depending on the location. Therefore, it is necessary to consult the public health center in each prefecture in advance.

Rapid and flash freezers for selling and increasing sales of frozen foods

Rapid or flash freezing is a method of freezing food in the shortest possible time.

When food is frozen using conventional freezing methods, the cells in the food deteriorate, resulting in a rapid deterioration of quality. However, rapid or flash freezing can prevent the deterioration of food cells to the maximum extent possible, allowing food to stay as fresh and tasty as possible compared its pre-freezing state.

For rapid freezing, you will need a special rapid or flash freezer.

The two main methods used rapid freezing are the air blast method, which uses cold air to freeze the food, and the liquid method, which freezes the food by immersing it in liquid. We will explain each method below

Air blast method

The air blast method is a method of freezing food by applying cold air.

This is a freezing method that is commonly used in general household freezers.

The ARTLOCK Freezer is equipped with a micro-wind system, which minimizes food deterioration (drying, cracking, etc.) by enveloping the food with gentle cold air and freezing it evenly.

Equipped with an AI control system, it is also possible to freeze piping-hot foods to preserve their fresh taste as the AI will regulate the temperature automatically.

Liquid method

The liquid method is a method of freezing food by placing it in a chilled liquid.

Liquids have high thermal conductivity, allowing food to be frozen quickly.

The Re-Joice Freezer rapid freezes food by placing in a tank filled with alcohol that is cooled to -35°C. Because it uses a liquid freezing method, no frost forms and it can operate continuously for 24 hours.

There are several methods for rapid or flash freezing, but the method that is compatible with each food differs. You need to experiment with different methods to pick the best and most suitable one for your food and business.

Conclusion

There are several ways to make frozen foods, and rapid or flash freezing is one of them.

To make frozen foods, you will need a rapid or flash freezer as it helps preserve your food's quality and can freeze products faster.

Additionally, the optimal freezing method varies depending on the food, so we recommend that you test different methods to see which one works for you.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![Freezing garlic, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/30693b4b122ff6c57afff367b35bc861.jpg)

![How to freeze zucchini and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/zucchini6-768x512-1.jpg)

![[Explanation of how to fry! ] Introducing how to freeze spring rolls and 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/8964429f347a4ffd32dca5809cd02100.jpg)

![How to freeze and thaw chestnuts, storage period, and 5 recipes! [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/c590a9e6fb16ed45fe2fdd32813de03b.jpg)

![[Convenient for lunch boxes! ] How to freeze fried noodles and 5 different recipes](https://shunkashutou.com/wp-content/uploads/2023/10/yakisoba-768x512-1.jpg)

![How to freeze grapes, thaw them, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/c773e4ee54900a04329b03d0df5c7834.jpg)

![[Thorough explanation! ] What is the distribution and cold chain that maintains the quality of frozen foods?](https://shunkashutou.com/wp-content/uploads/2016/11/ed15366b2a889239b39608c181587427.jpg)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2024/10/99093c5fe8b0d716c39df907616e4a96.webp)

![[Deliver delicious ham! ] Meat processing manufacturer’s rapid freezing implementation example](https://shunkashutou.com/wp-content/uploads/2024/09/0825c4a97ac8495fd2408a91574cede6.webp)

![[How long does it last? ] How to freeze cooked rice and how long it can be stored](https://shunkashutou.com/wp-content/uploads/2023/10/7e31499b015d58f220536e3274a41bf2.jpg)

![[Explanation with photos! ] How to freeze hijiki and its storage period, 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/ff6bdc527dd066b7d725a48161d7925d.jpg)

![How to freeze rice cake, expiry date, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/bd019f04ad570f697ffefe9ffd2e1e71.jpg)

![How to freeze/thaw turnips, storage period, and 5 recipes [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/eae0789d04cc4971cf4232963b4d2231-1.jpg)

![[Explanation with photos] How to freeze peaches, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/b454a38d482a64b14d55d2560aa4193a.jpg)

![[Increase sales! ] Three reasons why ramen restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/08/deb66347f085932482279d9069d398c8.webp)

![[Successful example of rapid freezing] Efforts of Yuko Fisheries Cooperative and regional revitalization by women](https://shunkashutou.com/wp-content/uploads/2024/10/68950ce21415f187d34a8a1d5b48956a.webp)

![[Easy installation and bulk storage] Prefabricated freezer functions and prices](https://shunkashutou.com/wp-content/uploads/2015/09/e52a1bacf6f05c6337143048f88802d7.jpg)