The solution is rapid freezing! Refrigeration technology that you should know

In the increasingly competitive restaurant industry, did you know that there is a dream-like technology that can deliver both delicious food and cost reduction? The technology is "rapid freezing technology."

With rapid freezing, you can preserve the taste and texture for decades. It will be possible to solve the problem of cost, which is a difficult point when handling fresh foods, while maintaining quality.

目次

Great explanation! The deliciousness of rapid freezing

Is there anything to be careful about when freezing food?

However, if you are freezing it, be careful. Freezing can preserve food for a long time, but it can also cause the taste to deteriorate.

Food is very delicate. It's not just a matter of popping it in the freezer to cool it; if you don't freeze it in a way that suits the food, the original flavor of the food will be lost. Proper freezing can dramatically change the quality of food after thawing.

Proper freezing means that the taste does not deteriorate even after thawing. rapid freezing technology has made this possible. The difference from conventional refrigeration lies in the method of cooling.

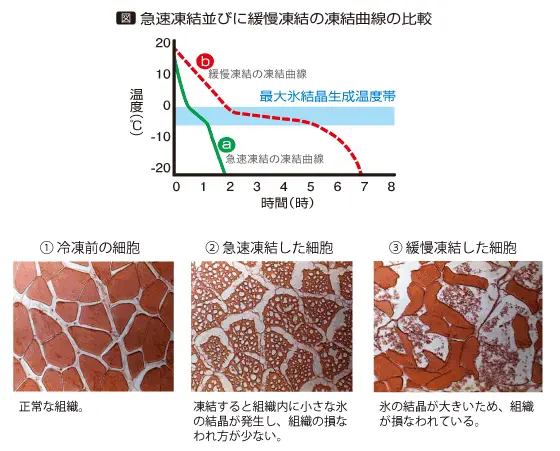

Water makes up 70-80% of food. When this water turns into ice, its volume expands and large ice crystals form inside the cells of the food. This destroys the cells in the food and causes the food to lose its flavor when thawed.

However, if the temperature range from water to ice can be passed through in the shortest possible time, the cell tissue can be frozen without being destroyed. The temperature range where water turns to ice (-1°C to -5°C) is called the maximum ice crystal formation temperature range, and if food can pass through this temperature range within 30 minutes, the quality of the food will not deteriorate. .

By cooling the food all at once, the taste, texture, and even nutrition can be returned to the same state as before freezing.

Basically, almost all foods can be frozen, except for fresh leafy vegetables and fruits. Since no drips occur during defrosting, you can reproduce the original taste of not only cooked foods but also raw meat and fish.

It has a good reputation for its taste, and has received tremendous support from many people involved in the food industry, including fishermen's associations, seafood processing companies, Japanese and Western confectionery stores, Wagyu beef retailers, and frozen sushi manufacturers.

Eye-opening! Eliminate loss and gain profits with rapid freezing

The biggest problem when handling fresh food is that it is difficult to control costs.

Since it is a perishable food product, it is natural for it to be discarded. Of course, there are labor costs. It is natural for a company to be in the red depending on the purchase price.

Do you take everything for granted and look away?

rapid freezing allows you to do things you couldn't do before.

If we could eliminate waste food...

Due to purchasing issues, there are times when we end up with surplus food or food that cannot be processed. Due to food hygiene, if it is difficult to use the next day, it must be thrown away.

However, if you rapid freezing and store it, you can use it the next day or even the next week. It can be stored for long periods of time, even decades. Of course, the quality does not deteriorate even if it is stored for a long time.

If we can reduce the number of staff...

The number of staff required for each store is determined. By centralizing food preparation in one location and rapid freezing the cooked food before distributing it to stores, the number of people needed at each store can be reduced.

Furthermore, you can also reduce utility costs such as equipment/tool costs and electricity costs.

If we can get stable supplies throughout the year...

For fresh foods, there are periods of high harvest and periods of low harvest, and purchase prices are not stable, so there will be times when you will be in the red. If you buy a lot of food when it's cheap, rapid freezing, and save it, you can use it when prices go up.

You will no longer be swayed by fluctuations in purchasing prices. Foods that can only be distributed during a specific period, such as seafood and wild vegetables that are closed to fishing, can be supplied year-round.

By properly understanding what losses are currently unnecessary, what losses you want to avoid, and how many losses can be avoided, you should be able to find hints that will lead to profits.

be on one's mind! Things about rapid freezer

I'm sure there are many people who think, "I understand what rapid freezing is, but it's hard to visualize."

Some people may be too familiar with the term rapid freezing" and have no idea what kind of machine it is. That said, the shape is similar to a commercial freezer.

However, the internal functions are more sophisticated than regular freezers.

rapid freezing machines can be broadly divided into two types: the air blast method, which freezes food with cold air, and the brine method (liquid method), which freezes food by immersing it in a low-temperature liquid.

Furthermore, they are divided into various types, including machines that use magnetic fields and electromagnetic waves, and machines that can be made to order.

Each has its advantages, and there are differences in ease of handling and freezing speed. It is not possible to say with certainty that this food should be frozen in this particular machine, so you must choose the machine that is most suitable for the food you want to freeze.

Sizes range from pins to holes, and you can choose one depending on the purpose. They range from small machines used in restaurants to large machines used in large-scale factories, and there are also types that can be automated by connecting to conveyors such as tunnel and spiral types.

Larger machines require plumbing work, but smaller machines can be installed with the space and power supply of about two household refrigerators.

And the price is a concern. The price ranges from around 1.5 to 3 million yen, and expensive machines can cost up to 100 million yen. Higher price doesn't mean better.

The most important criterion when choosing a machine is what you want from refrigeration.

The current situation is that there are machines on the market that are labeled as rapid freezer but do not have reliable performance.

It is necessary to collect the correct information and carefully examine which machine is most suitable.

Conclusion

We live in an era where customers are no longer satisfied with just being cheap or delicious.

By solving the two issues of quality and cost, we can achieve even better results than we currently have.

As a further challenge, why not consider installing rapid freezer?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Should be frozen! ? ] How to freeze and thaw bread, 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/4691acc32cab80284fa0cddf72d58e95.jpg)

![Introducing how to freeze and thaw whitebait, as well as recipes for its use [Full of nutrition! ]](https://shunkashutou.com/wp-content/uploads/2023/10/04d15012ec36f91a5574f63dfa9d4771.jpg)

![[How to use leftover sashimi! ] Introducing frozen preservation methods and arrangement recipes](https://shunkashutou.com/wp-content/uploads/2023/10/7451dbe2231dbc559fe002350b8add67.jpg)

![How to freeze zucchini and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/zucchini6-768x512-1.jpg)

![[Can it be frozen? ] How to freeze cabbage rolls, storage period, and recipe](https://shunkashutou.com/wp-content/uploads/2023/10/f5c1db9a17ef7843ffd45f5ccb160ed5.jpg)

![Explaining how to freeze tempura with photos! [Storage period, thawing, carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/10/51f33cde78d02d01a9e827132e4f069d.jpg)

![[Food/processing manufacturers] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_kakou_img_01.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Thorough explanation! ] What is the distribution and cold chain that maintains the quality of frozen foods?](https://shunkashutou.com/wp-content/uploads/2016/11/ed15366b2a889239b39608c181587427.jpg)

![[Improve customer satisfaction] What can be solved by introducing rapid freezer at a lunch box delivery company for the elderly?](https://shunkashutou.com/wp-content/uploads/2024/07/c8a5aa8730d5ae7441fd1aa6ee8757ef.webp)

![[Successful example of rapid freezing] Efforts of Yuko Fisheries Cooperative and regional revitalization by women](https://shunkashutou.com/wp-content/uploads/2024/10/68950ce21415f187d34a8a1d5b48956a.webp)

![[Wholesale] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_oroshi_img_01.jpg)

![[Explanation with photos] How to freeze nagaimo, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/c46c238f2048d76de403dfd81ddad1f3.jpg)

![[For the lunch box manufacturing industry] Business issues can be solved by using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/04/f93f171f5d29bdb15c4b8d06e244b002.jpg)

![[Fisheries/Fisheries Cooperative] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_suisan_img_01.jpg)

![How to freeze sweet potatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/36256af24531b73a036523ba73bdf9ec.jpg)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[Freezing Neapolitan] rapid freezing demonstration](https://shunkashutou.com/wp-content/uploads/2016/09/napolitan.jpg)

![[For maintaining food quality!] Three functions you should know about constant temperature and high humidity storage](https://shunkashutou.com/wp-content/uploads/2015/10/krefrigerator.jpg)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/07/2a0deb9a6db53165f0a4938bc80cee46.webp)

![[Labor shortage]The benefits with examples of using rapid freezer](https://shunkashutou.com/wp-content/uploads/2019/04/hitodebusoku-article-main_pc.jpg)

![[Rapid freezers in 2021] Market Trends and Customer Success Stories](https://shunkashutou.com/wp-content/uploads/2020/12/7F9A9CB9-A494-4E6A-946E-079279C596E6.jpeg)

![[Easy thawing method] Low temperature thawing to lock in the deliciousness of meat](https://shunkashutou.com/wp-content/uploads/2024/08/899e71a518bbd73569bf085ff0accd61.webp)