[Shop for carefully selected fresh udon] 5 reasons why udon restaurants should introduce rapid freezing

Udon shops across the country are probably struggling with issues such as difficulty in expanding sales channels and waste loss due to the short shelf life of handmade udon noodles.

The shelf life of noodles is so short that they are said to be living things, and the wheat flavor fades and the texture changes as time passes after making them. Generally, fresh udon noodles only last for about 1 to 2 days after being made.

However, all of these problems faced by udon restaurants can be solved by rapid freezing.

Some of you may be wondering, "What exactly is rapid freezing?"

This time, we will introduce the benefits of introducing rapid freezer to a udon restaurant, as well as actual success stories of rapid freezing.

A must-see for those who are currently having trouble selling udon noodles!

目次

- 1Does udon deteriorate even if stored in the freezer?

- 2What are the challenges faced by udon restaurants?

- 3 Is it possible to maintain the quality of udon noodles by rapid freezing?

- 4 General benefits of rapid freezing

- 5 5 reasons why udon restaurants should introduce rapid freezing

- 6 Success stories of udon shops

- 7 Conclusion

Will udon deteriorate even if stored in the freezer?

Udon is prone to quality deterioration

After all, a major hurdle in manufacturing udon is the quality deterioration over time.

Storage at room temperature: 1 day

Refrigerated storage: up to 1 week

Storage at room temperature: Less than half a day (quality deteriorates significantly)

Refrigerated storage: About 3 days (quality deteriorates significantly)

Over time, raw udon and boiled udon tend to deteriorate, such as losing flavor and changing texture. Furthermore, it may deteriorate over time.

Changes in ``body'' and ``throat'', which are important in determining the quality of udon, are also a major issue.

What are the issues with frozen udon?

As frozen udon noodles are generally widely used, ``freezing'' is an effective means of preserving food to prevent changes in quality.

However, can frozen udon really reproduce "authentic hand-made udon"?

``We wanted to deliver carefully selected udon noodles to our customers, so we tried slow freezing (normal freezing), but it wasn't enough to recreate the taste of the restaurant.''

We often hear from our customers.

If you freeze udon noodles using slow freezing, this problem will occur after thawing.

・Lose stiffness

・Noodles break easily

・Sore throat becomes worse

Why does slow freezing cause quality deterioration?

This includes the following factors:

Causes of deterioration due to freezing

① Damage to noodle tissue

When frozen over a period of time, the water contained in the noodle tissue sticks together to form large ice crystals, and the gluten proteins and starch molecules surrounding them are also tightly condensed and bonded together.

Even when udon is thawed, these bonds are not broken, so only the ice crystals melt away, leaving a cavity inside the udon noodles. During frozen storage, moisture evaporates through these holes, causing dryness.

② Starch deterioration

When starch is heated with water, it becomes viscous and gelatinizes (as in freshly cooked rice). When the gelatinized starch is cooled, the amylose and amylopectin contained in the starch separate water molecules, which removes water and dries it.

This is called starch retrogradation, and it becomes particularly active between 2 and 4 degrees Celsius, just before the water freezes. This temperature range matches the temperature range of a refrigerator, so many starch-containing foods are not compatible with refrigerator storage.

Udon is a lump of starch, and once boiled, the starch is in a gelatinized state, so if you cool it down over time, the starch will inevitably deteriorate. Therefore, how quickly the udon passes through the temperature range where it ages is important in determining the quality of the udon. As the starch ages, the noodles break, become sticky, and become watery.

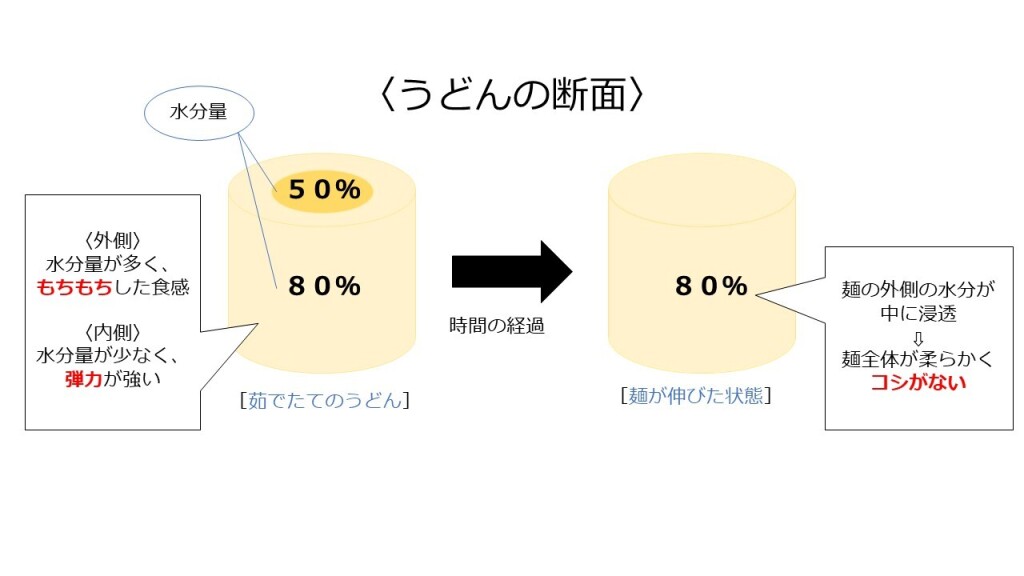

③ Equalization of moisture

After boiling, the water in the udon noodles permeates from the outside to the inside, and the water becomes even. At this point, the udon noodles lose their firmness and become stretchy.

Slow freezing takes a long time to freeze, so the boiled udon inevitably becomes uniform and loses its firmness.

In other words, slow freezing (normal freezing) is not sufficient to maintain the quality of udon noodles.

What challenges do udon restaurants face?

Udon restaurants have the following issues because udon noodles have a short shelf life and their quality deteriorates even when frozen.

① Cannot sell on EC site

It is not possible to expand sales channels because the quality deteriorates by the time it is delivered to a distant place.

②The quality of takeout products is significantly inferior to products offered in stores.

Demand for takeout has increased in recent years, but in the case of udon, customers cannot enjoy the same quality of udon at home as in stores.

③Unable to sell to restaurants that require high quality udon

The time that passes between making the udon noodles by hand and the time it reaches the restaurant causes it to deteriorate, making it impossible to sell it to restaurants looking for high-quality udon.

④ Occurrence of waste loss

Udon takes a long time to boil, and is often prepared in advance in anticipation of demand. If demand cannot catch up with supply, waste will occur.

Also, if it takes a long time from preparation to serving, the noodles will lose their firmness. (After 30 minutes of boiling, it loses its firmness that it had immediately after boiling.)

⑤ There is a limit to the supply amount.

If there are only a small number of craftsmen making udon, there is a limit to the amount of production. We may not be able to respond to sudden orders.

I'm sure many of you have this in mind. How can we solve the above problems?

Is it possible to maintain the quality of udon noodles by rapid freezing?

We mentioned earlier that it is difficult to provide the highest quality udon noodles through slow freezing (normal freezing).

However, it is possible with "rapid freezing ".

rapid freezing overcomes the problems associated with frozen udon, such as drying of the noodles, changes in texture, and loss of flavor.

What exactly is rapid freezing?

About rapid freezing

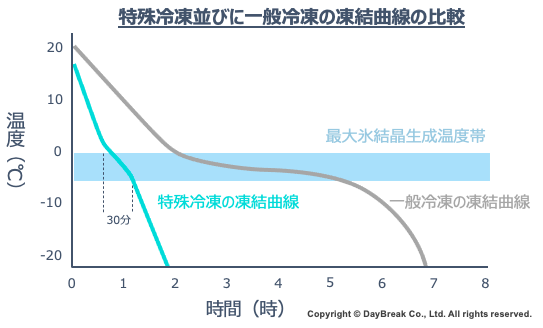

In general, during slow freezing (normal freezing), the water inside food cells turns into ice crystals.

In slow freezing (normal freezing), water freezes slowly and water molecules bond with each other, resulting in larger ice crystals.

The larger ice crystals pierce the food cells from the inside, creating holes in the cells. These holes are a major cause of food quality deterioration.

When frozen food is thawed, flavor components and nutrients flow out along with the water through these holes and are lost. (What is called drip)

The temperature range where the water in food crystallizes is called the "maximum ice crystal formation temperature range", and the quality of the food after thawing is determined by how quickly it passes through this temperature range.

Because rapid freezing passes through this temperature range much more quickly than slow freezing, the crystals that form inside cells become smaller, allowing cells to be frozen without destroying them.

Foods that are frozen without cell tissue being destroyed will almost never drip when thawed, retaining their freshness, texture, and flavor, and can be returned to a state that is almost the same as before freezing.

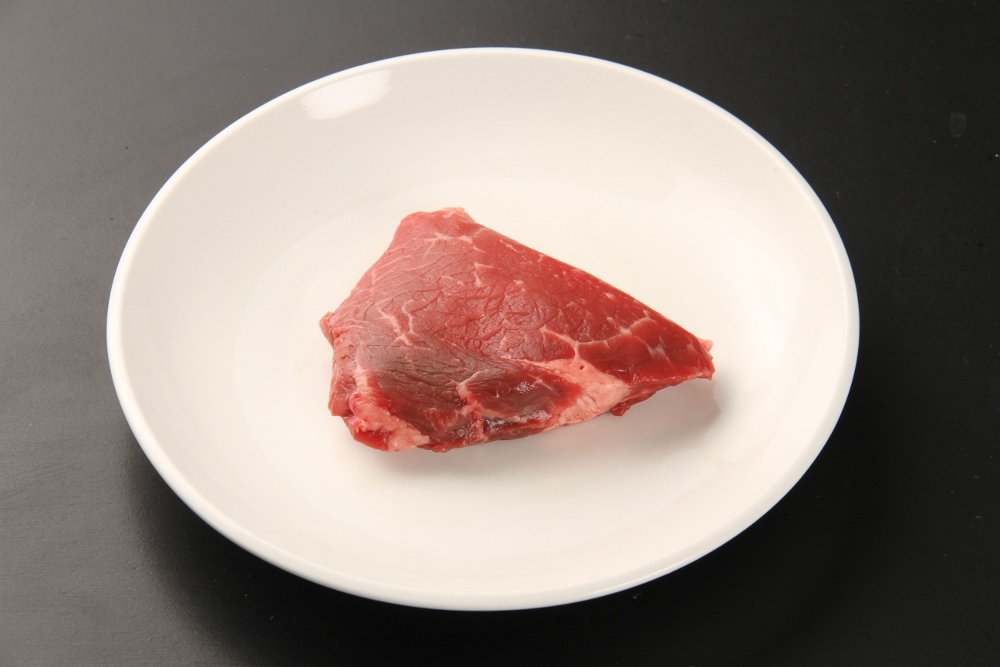

This is a comparison photo of rapid freezing and slow freezing. rapid freezing produces no drips, and you can see the difference in quality.

rapid freezer called Artlock Freezer that we handle does not lose the flavor of the wheat, which is a problem when freezing udon noodles, it maintains the firmness of the noodles, and prevents the noodles from drying out..

Features of Art Lock Freezer

The Artlock Freezer freezes food by exposing it to air, and its features are as follows.

・Micro window system

Equipped with a new mechanism that increases the efficiency of cooling food without damaging the food by using cold air based on a special principle. This prevents the udon noodles from drying out and improves the ``difficulty swallowing'' and ``mushy feeling'' caused by cracks on the surface of the udon noodles.

・No need for packing

By being able to freeze the food you want to freeze naked, it not only saves you the hassle of packing it, but also prevents deformation and discoloration caused by packing.

・No need for cooling (rough heat removal)

The real-time control system automatically adjusts to the optimal freezing conditions even if you put piping hot food in it. When freezing boiled udon noodles, you can freeze them without cooling them, making the process much more efficient. The space and time previously occupied during cooling can be effectively utilized.

There is also rapid freezer called the "Rejoice Freezer," which uses a liquid-based freezing method.

Features of Rejoice Freezer

・Liquid such as alcohol is the medium

Liquids have high thermal conductivity and can be frozen in a shorter time than air freezing.

・Packing required

Although it is not suitable for products that easily lose their shape, it can be an advantage as they can be sold as is, depending on how they are sold afterwards.

Artlock freezers allow you to freeze udon noodles with a stronger wheat flavor, while Rejoice freezers allow you to freeze udon noodles in a shorter amount of time.

There are several ways to defrost food, such as thawing under running water, boiling, microwave, and steam convection, but each has its pros and cons, so the optimal thawing method will vary depending on the method of freezing.

We have professionals who are familiar with rapid freezing, so please feel free to contact us.

General benefits of rapid freezing

By introducing rapid freezing, you can keep food in a delicious state and achieve the following.

Improve sales by expanding sales channels

Started selling through mail order and wholesale. By rapid freezing freshly made products, we can provide almost the same quality even after thawing.

Eliminating labor shortages

Planned production will become possible, and employees will be able to work in a stable manner throughout the year. Employee retention rates have increased, and we no longer have to worry about labor shortages.

When there is a shortage of manpower, it is possible to reduce working hours, thereby reducing labor costs and increasing sales.

Improving work efficiency

Refrigeration efficiency has been improved, making it possible to freeze faster than existing refrigeration equipment. In addition, since there is no need to defrost products, products can be frozen even during times when operations could not be performed, increasing production volume.

Eliminating food waste

rapid freezing allows you to preserve products that maintain their quality for a long period of time, making it possible to stock products. By always ensuring inventory, we prevent opportunity loss and also reduce waste loss.

In addition, by rapid freezing, it can be sold nationwide.

Improving food quality

Normal freezing methods often fail to reproduce satisfactory quality, such as leakage of flavor components and discoloration. rapid freezing enables long-term storage and adds value to products.

*Fresh fish can be rapid freezing to prevent loss of freshness. Some research has shown that frozen foods have more nutrients.

Generally speaking, the above is achieved, but what kind of effects can be achieved in the production of udon noodles?

5 reasons why udon restaurants should introduce rapid freezing

In general, it has the benefits I mentioned earlier, but what kind of effects can you expect for udon restaurants?

EC site sales are difficult.

It is not possible to expand sales channels because the quality deteriorates by the time it is delivered to a distant place.

【Benefits】

It is now possible to preserve high-quality udon noodles and expand sales channels. rapid freezing freshly made or boiled udon noodles, it is now possible to deliver high-quality udon noodles to distant locations. Sales increased significantly.

We sell udon noodles for takeout and souvenirs.

Demand for takeout has increased in recent years, but in the case of udon, customers cannot enjoy the same quality of udon at home as in stores.

【Benefits】

Available for take-out from udon restaurants or as souvenirs. You can enjoy high-quality carefully selected udon noodles at home. Another point is that it has a longer shelf life than fresh udon, so you can eat it whenever you want.

We cannot sell udon for commercial use to restaurants that require high quality udon.

The time that passes between making the udon noodles by hand and the time it reaches the restaurant causes it to deteriorate, making it impossible to sell it to restaurants looking for high-quality udon.

【Benefits】

By selling wholesale to specific restaurants for commercial use, you can ensure stable demand and sales.

Generation of waste loss

Udon noodles take a long time to boil, so they are often prepared in advance in anticipation of demand. If demand cannot catch up with supply, waste will occur.

Also, if you prepare udon noodles in advance, they will lose their firmness over time. (If 30 minutes have passed after boiling, it will lose its firmness immediately after boiling.)

【Benefits】

By lightly boiling udon noodles rapid freezing, and storing them in stock, you can shorten the cooking time. Now that the noodles are cooked after an order is placed, we can always provide freshly boiled udon noodles, which has been well received by customers. Reduces waste when supply and demand forecasts do not match.

supply is limited

If there are only a small number of craftsmen making udon, there is a limit to the amount of production. We may not be able to accommodate sudden orders.

【Benefits】

By planning production when you have free time, you can respond to sudden orders and eliminate opportunity losses. Working hours, which used to be variable, will become more stable, which will help retain employees.

There are other benefits as well.

・Providing safe and secure udon noodles that do not use preservatives.

・By rapid freezing udon toppings, etc., the effort required for preparation is reduced.

In particular, deep-fried foods such as tempura take a lot of time to prepare, so rapid freezing greatly improves operational efficiency. By purchasing seasonal ingredients in bulk, you can provide high-quality food all year round.

・By being able to manufacture udon in bulk, it is possible to open multiple stores.

Even stores without udon professionals can provide high-quality, carefully selected udon noodles.

Success story of udon store

We would like to introduce a case study of an udon restaurant that actually introduced rapid freezer and succeeded in increasing sales.

Introduction example ①

This is an example of how we were able to provide freshly boiled udon noodles to families.

◇Purpose

I want you to eat chewy raw udon noodles at home with the same quality as at the store.

◇Challenges

Freshly made udon noodles were sold as souvenirs, but it is extremely difficult to produce chewy fresh udon noodles that are the same as those made by artisans using the heat of a home kitchen.

They were looking for ways to reproduce the quality of the store's products at home, and had plans to freeze the food they boiled in-house and commercialize it, but things didn't go well.

◇Results after implementation

As a result of focusing on quality in order to freeze the flavor, only rapid freezer could recreate the flavor of authentic udon without additives.

With the introduction of rapid freezer, it is now possible to serve authentic udon noodles that can be eaten at home by simply boiling the frozen noodles in hot water.

◇Aftereffects

Since customers can enjoy the restaurant's flavors at home, the number of customers increases through word of mouth, and the number of repeat customers also increases, creating a virtuous cycle.

Souvenirs are shipped several times a day via courier service, and the number of people using the service for mid-year and year-end gifts is increasing as the company has gained fans.

Introduction example ②

The second example is an example of increased sales due to reduced waste loss.

◇Purpose

Reducing waste

◇Challenges

Boiling the udon noodles after customers arrived would take time and slow down the turnover rate, so they predicted demand and boiled the noodles in advance. If there is a difference between the expected amount and the actual required amount, it will be discarded.

As time passes, the water content of boiled udon noodles becomes uniform, causing the noodles to lose their unique elasticity and chewy texture.

◇Results after implementation

Cooking time can be shortened by boiling the udon noodles a little and then rapid freezing. There is no need to boil the udon noodles in advance, eliminating waste. In addition, we are now able to always provide freshly boiled udon to our customers, improving quality. It is also highly rated by customers.

We introduced a successful case study of a udon restaurant that actually introduced rapid freezer.

Conclusion

How was it?

Many of the problems faced by udon restaurants can be solved by rapid freezing. And the profits that can be made by introducing rapid freezer are huge.

Furthermore, you can develop a business that is one or two ranks higher than the current one, such as reducing waste loss and expanding sales channels.

Why not take this opportunity to consider installing rapid freezer?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Freezing Ramen] rapid freezing demo](https://shunkashutou.com/wp-content/uploads/2017/04/5bd196dffb982354d8f83114a5f7bdf2.webp)

![[Freshly made raw soba all over the country! ] Example of introducing a quick freezer at a soba restaurant](https://shunkashutou.com/wp-content/uploads/2016/01/6d8138adcf26c410c11b25d5b8d2f3de.jpg)

![[Convenient for lunch boxes! ] How to freeze fried noodles and 5 different recipes](https://shunkashutou.com/wp-content/uploads/2023/10/yakisoba-768x512-1.jpg)

![[A little different! ? ] How to defrost frozen udon and 7 different recipes!](https://shunkashutou.com/wp-content/uploads/2023/08/91fb1e27ec38400acc9b3b6ca6233f65.jpg)

![[Commercial rapid freezer] Explaining the features, size, and price of Panasonic rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/01/panasonic.jpg)

![[Easy installation and bulk storage] Prefabricated freezer functions and prices](https://shunkashutou.com/wp-content/uploads/2015/09/e52a1bacf6f05c6337143048f88802d7.jpg)

![[Increase sales! ] Three reasons why ramen restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2016/04/ra-men-reitou.jpg)

![[Manufacturing subsidies are recommended for rapid freezer! ] Explaining the ABCs of application](https://shunkashutou.com/wp-content/uploads/2020/12/4024568_s.jpg)

![[Eliminating the labor shortage! ] Introducing the benefits of the cook-freeze system!](https://shunkashutou.com/wp-content/uploads/2018/12/95e9f56fecc5fd995cb205bd5b13596c_s.jpg)

![[Long-lasting freshness! ] Explaining the advantages and disadvantages of chilled storage and chilled transportation](https://shunkashutou.com/wp-content/uploads/2016/11/64b437bd976e4ef73a85dbb64cdf9fc8.jpg)