The key to maximizing profits for a butcher shop is cost management and creating a reason for products to sell even at a high price.

What should you keep in mind to maximize your profits as a butcher?

Running a butcher shop has an image of being a profitable business, but it is currently plagued by rising prices of imported meat due to the recent weak yen, rising prices of domestic meat due to rising feed costs, and rising logistics costs due to the 2024 problem.

Even if there is stable demand, the current situation is that they cannot expect to make large profits unless they can contain rising costs, and many butchers are probably racking their brains over how to deal with this.

Regardless of the profit structure of any business, the general method for maximizing profits is to reduce cost rates and waste losses and increase sales, but in the case of butcher shops struggling with rising costs, we will explain how they can maximize profits, focusing on methods that incorporate the popular freezing technology.

目次

- 1.What is a butcher's cost ratio?

- 2. Cost calculation method for each part

- 3 Measures butchers can take to reduce their cost rates

- 4 Keys to butchers increasing profit margins

- 5. Improving added value in butcher shops

- 6 Benefits of installing rapid freezer in a butcher shop

- 7 Best Art Lock Freezers for Butcher Shops

- 8 summary

What is a butcher's cost ratio?

The cost rate refers to the percentage of the purchase cost in the selling price of a product. The ideal cost rate for a typical butcher shop is around 30%. However, since the value and cost of meat varies depending on the type and cut, it is necessary to set selling prices and control costs by type and cut.

The cost ratio is key to increasing the profitability of butcher shops. Here, we will explain cost ratios unique to the meat industry and delve into approaches to improving profits.

Cost rate management that leads to increased profits at butcher shops

For butcher shops to maximize profits, it is essential to understand and manage the appropriate cost rate. A complex set of measures is required, including inventory management to avoid excessive loss, preservation techniques to keep meat fresh, and pricing of the final product. By managing the appropriate cost rate, butcher shops can ensure sustainable profits and increase their competitiveness.

Cost calculation method by part

Cost calculation by cut is essential for cost management in butcher shops. By performing this calculation accurately, you can maximize profits by minimizing waste and setting profitable prices for each cut. Below, we will take a deeper look at how to calculate cost by cut.

Key points for accurate calculations

Accurate weight measurements are essential when calculating the cost of each cut. Also, because prices vary depending on the quality and grade of meat, these differences must be properly reflected in the calculation.

Efficient calculation methods using software

Modern accounting software can help you calculate part-by-part costs efficiently and accurately. Many accounting programs go beyond cost calculations to help with other aspects of running your business, such as inventory management and sales analysis.

Using such tools can reduce manual calculation errors and save time.

| Location | weight | market price | Cost |

|---|---|---|---|

| Ribeye | 3kg | ¥2,000/kg | ¥6,000 |

| sirloin | 2kg | ¥2,500/kg | ¥5,000 |

| Fin | 1kg | ¥3,000/kg | ¥3,000 |

The above table clearly shows the cost calculation for each part. Cost calculation can be complicated because it includes a wide range of factors such as purchase price, labor cost, and various expenses related to store operation, but it is important to calculate by taking these factors into consideration comprehensively. Calculating the cost by part is an essential process for setting optimal prices and increasing store profitability.

As mentioned at the beginning, butcher shops have an image of being profitable businesses, but in reality they struggle with complex cost management and take measures to increase profits.

In order to maximize profits as a butcher shop, we will propose measures to reduce cost rates as well as other policies that should be implemented.

Measures taken by butchers to reduce cost rates

Butcher shops are primarily run by retail sales and wholesale, but reducing the cost rate is essential to maximizing profits. First, we will explain the specific methods for effectively lowering the cost rate.

Review of procurement

As the first step in reducing the cost rate, it is important to review your purchases. Examples include reducing unit prices by purchasing in bulk, making purchase plans that take into account seasonal and market trends, and reviewing prices through negotiations with suppliers. Securing appropriate purchase prices is directly linked to reducing the cost rate, so active review is required.

Initiatives to reduce waste

Waste loss in butcher shops is one of the factors that greatly affect the cost rate. It is possible to lower the cost rate by reducing product loss. We will develop specific methods for reducing loss, such as improving inventory management, determining appropriate order quantities by analyzing data on popular items, and appropriate storage methods to maintain the freshness of products.

Optimizing the menu structure

Reviewing the products and menu composition offered at your butcher shop is also an effective way to reduce cost rates. Menu improvements can have a wide range of effects, such as reviewing products with high cost rates, proposing products with higher profit margins, and promoting sales by devising pricing for each part of the meat. If you want to raise prices, improve them by adding added value.

| countermeasure | Concrete example | Expected effect |

|---|---|---|

| Review of procurement costs | Purchasing and price negotiations according to season and market trends | Improved cost rate by reducing purchase prices |

| Loss Reduction | Optimize inventory management and implement proper storage methods | Reduce disposal costs and improve profit margins |

| Menu Improvements | Promote high-profit products and optimize pricing by adding value | Reducing high-cost products and maximizing profits on popular products |

The above table outlines three cost reduction strategies that can be implemented in butcher shops, along with specific examples and expected results. Managers and store managers should use this information to devise and apply the strategies that are best suited to their own stores.

The key to butchers increasing profit margins

In order to increase a butcher shop's profit margin, in addition to reducing cost rates and waste as mentioned above, measures to increase sales are necessary.

Sales are from beef, and gross profit is from pork and chicken.

Beef has a high unit price, so sales will grow significantly. Pork and chicken have a higher gross profit margin than beef, but because they are low-priced, sales will not increase no matter how much they are sold.

It is easier to increase sales by expanding the beef lineup and selling more of it than by selling a lot of pork or chicken. However, since it is not possible to sell a lot of expensive beef, it is a good idea to supplement the gross profit with pork and chicken.

Focusing on meat dishes to secure gross profit

By meat type, the gross profit margin for beef is low, for pork and chicken it is just under 30%, and the highest gross profit margin is for meat preparations. Focusing on convenient meat preparations that can be bought and eaten immediately is a key point for butcher shops aiming to improve their profit margins.

The strategy of focusing on selling meat deli dishes symbolizes the idea of "adding value to products and creating a situation where they can be sold at high prices." In fact, more than simply reducing various management costs, it is very important to be aware of increasing the value of products and creating a system that allows them to sell at a fair price or higher.

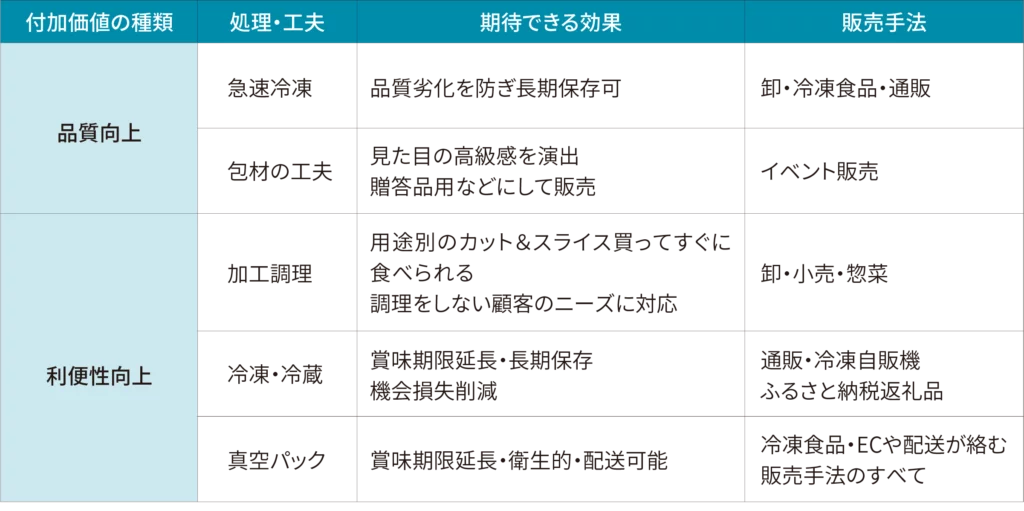

Adding value to butcher shops

Adding value in butcher shops means processing and cooking products so that customers perceive the product as having more value than just the meat itself, and are motivated to buy it even if it is more expensive.

There are several ways to expand sales channels while keeping initial costs and labor costs down, such as mail order sales, frozen vending machines, hometown tax payments, etc., by producing high-quality frozen products or by processing and cooking products to enhance convenience. However, in order to expand sales channels for meat in this way, high-quality freezing processing and the development of frozen products with increased added value are essential.

We will introduce the benefits of using rapid freezer to make this possible.

Examples of using rapid freezer

Here we will introduce some familiar examples of how rapid freezer can be used to expand a store's product lineup and increase sales.

Buy raw materials at low prices and sell them at high prices

For example, in the summer, the number of people having BBQs increases, so the demand for meats such as kalbi, skirt steak, and loin for BBQs increases. It is common that the cost of meat also increases when demand increases, so if you purchase meat cheaply when demand is low, freeze it, and then thaw and sell it when demand increases, you can sell it at a higher price and improve your profit margin.

Eliminate opportunity loss by selling rare cuts

Since high-quality cuts such as Chateaubriand are purchased infrequently and are prone to waste, some stores may not include them in their product lineup.

By rapid freezing parts that are purchased less frequently, we can extend their expiration date and increase our product lineup without generating waste.

By increasing the product lineup on display in stores, you can reduce opportunity loss and increase sales. In addition, a wide selection of products also leads to an improved image of the store.

Sold as frozen meat deli dishes

For example, if you sell high-demand meat dishes such as croquettes, fried chicken, and pork cutlets as high-quality frozen products, people who don't want to eat them right away can buy them to take home, and you can differentiate your products by offering a fresh, crispy texture that is better than regular frozen products.

Prepared meals have a higher gross profit margin than meat, so if the products become more popular, you can expect sales to increase.

Sold as frozen meat for stock

Just as households freeze leftover meat, there is also an increasing need to stock meat that will not be used immediately. If we could sell meat that has been frozen to a higher quality than usual, more people might want to buy the higher quality frozen meat to stock up on. If the reputation spreads that it tastes better than regular frozen meat, it would lead to increased sales.

The above are only a few examples of how rapid freezer are used, but with some ingenuity in rapid freezing technology, there is a wealth of potential for butcher shops to increase the added value of their products in terms of quality and convenience, and make a significant contribution to expanding their sales.

Examples of economic benefits

| Before improvement | After improvement | Reduction rate |

|---|---|---|

| Cost rate: 40% | Cost rate 28% | 30% reduction |

| Waste rate 5% | Waste rate: 3% | 40% reduction |

| Annual loss amount: 10 million yen | Annual loss: 6 million yen | 4 million yen reduction |

This table shows the economic benefits of the cost rate improvement measures implemented by a butcher shop. By reducing the cost rate, the butcher shop achieved a cost reduction of 4 million yen per year, which directly led to an increase in sales. The reduction in waste loss also led to a large profit, and it is expected that the butcher shop will avoid losses of more than 6 million yen per year.

Benefits of installing rapid freezer in a butcher shop

What is rapid freezing technology?

rapid freezing technology is a technology that quickly freezes food, minimizing cell damage and preventing quality deterioration. This technology makes it possible to maintain the freshness and flavor of meat for a long period of time, and can greatly contribute to improving the quality of product management and store management in butcher shops.

Maintaining high quality and reducing waste

By installing rapid freezer, the quality of purchased meat can be maintained for a long period of time, which leads to a reduction in waste. In addition, by purchasing meat in bulk during the season and storing rapid freezing, it is also possible to reduce raw material costs.

In addition, for butchers, reducing the risk of waste will enable them to purchase expensive, rare cuts of meat and manage their inventory, increasing their product lineup, reducing opportunity loss, and increasing sales.

Frozen products and expanding sales channels

Our technology enables us to freeze meat to a high quality, making it possible to produce fresh frozen meat products.

If the frozen products are then vacuum packed, they can be transported long distances, which opens up a wide range of sales possibilities, such as mail order, frozen vending machines, and gifts in return for hometown tax donations, which can lead to a significant increase in sales and improved profit margins.

Labor improvement and business efficiency

I think most meat processing and cooking is done early in the morning before the store opens. This can be a burden and lead to labor shortages, but if meat can be frozen and stored, it can be processed and cooked at any time, which is a major benefit as it can reduce work hours and improve the working environment.

Economic Benefit and Operational Cost Analysis

The economic benefits of introducing rapid freezer are clear from the reduction in losses due to the extension of storage period and the reduction in purchasing costs. However, since the initial investment in the equipment and the power consumption during operation are additional costs, it is necessary to analyze the operating costs and consider the cost performance from a long-term perspective. The table below summarizes the analysis of operating costs and expected economic benefits.

| item | Cost (initial/maintenance) | Expected economic impact |

|---|---|---|

| Initial investment costs | Expensive (varies depending on equipment selection) | Providing high-quality meat products through long-term quality maintenance |

| Operational costs | Periodic power consumption | Improved cost rate by reducing loss rate |

| Reduce procurement costs | Reducing variable costs | Stable procurement is possible without being affected by market price fluctuations |

As mentioned above, it is true that introducing rapid freezer requires a large initial investment.

However, when considering long-term operation, it is easy to imagine that the performance and economic benefits that can be gained from this, such as reduced cost rates and waste, improved production efficiency, and improved labor, are even greater.

Among these rapid freezer, we most highly recommend the Art Lock Freezer, which is highly regarded for its ability to achieve high-quality freezing of meat and fresh fish.

Art Lock Freezer - Best for Butcher Shops

If you are a butcher shop considering introducing rapid freezer, we recommend the Art Lock Freezer, which has earned overwhelming confidence and a high reputation for freezing meat.

We will explain the features of the Art Lock Freezer and why it is chosen by so many butcher shops.

It can freeze meat quickly while preventing it from drying out.

The Art Lock Freezer uses a special cold air generated by a fan structure called a micro window system, which allows for quick freezing while preventing ingredients from drying out, cracking, discoloration or dripping. This keeps the meat fresh and recreates a fresh state even after thawing, making it possible to achieve ideal freezing quality that is differentiated from conventional freezing for businesses that purchase meat and need to cook or process it.

No need for defrosting, high production efficiency

Art Lock freezers have an anti-frost structure that makes it difficult for frost to form inside, eliminating the need to stop the machine from operating every few hours to defrost.Since it can perform continuous freezing, it can produce frozen foods more efficiently in less time than a regular rapid freezer.

Prevent freezing failures and machine breakdowns

The Art Lock freezer is equipped with a sensor inside, so you can put food inside and the freezing process will be fully automatic without any detailed settings. The sensor inside the freezer detects the amount and temperature of the food inside, and selects the most optimal and efficient operation and processing.

This makes it easier to operate and improves work efficiency, with fewer freezing errors or mechanical breakdowns, even when used by people with no knowledge or experience.

Conclusion

In this article, we have proposed "cost calculation by part of meat, measures to reduce cost rates and increase added value" that butchers should implement to maximize their profits, and have explained the benefits of rapid freezer that can make this possible.

By introducing rapid freezer into a butcher shop and utilizing freezing technology in its operations, it is possible to control costs and increase added value, which is expected to significantly improve store profits.

Butchers today are particularly facing challenges such as rising raw material costs and intensifying price competition with imports. We hope that more people in the meat industry will realize that by incorporating the latest ICT-based freezing technology, such as the Art Lock Freezer, and improving the preservation quality and value of meat, they can solve many of their management issues.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2024/09/661ea3ee6264fab6520017622c656870.webp)

![[Thorough guide to preserving meat] Preservation methods, expiration dates, thawing methods, rapid freezing](https://shunkashutou.com/wp-content/uploads/2023/09/ec61889773cfed9c75aa97d9ca6c96dd-1.jpg)

![[Explanation with photos! ] How to freeze beef, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/8717f2a867f52157bab47841b0f29019.jpg)

![[Explanation with photos! ] How to freeze pork, expiration date, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/8688cd28f298c3180c30169cec815293.jpg)

![[Introducing tricks and time-saving techniques! ] How to freeze ginger-yaki, carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/10/ef145c31655c5774469e05b5e892207b.jpg)

![How to freeze chicken, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/01f6582931e13522ee0d1ee900be2d1d.jpg)

![[Guide to handling frozen chicken for commercial use] How to thaw and how long it can be used after that](https://shunkashutou.com/wp-content/uploads/2018/04/36a79f65c113cc4318afbc48fa6229b7.webp)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[Rapid freezers in 2021] Market Trends and Customer Success Stories](https://shunkashutou.com/wp-content/uploads/2020/12/7F9A9CB9-A494-4E6A-946E-079279C596E6.jpeg)

![[Manufacturing subsidies are recommended for rapid freezer! ] Explaining the ABCs of application](https://shunkashutou.com/wp-content/uploads/2020/12/4024568_s.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Freezing pickles] rapid freezing demo](https://shunkashutou.com/wp-content/uploads/2016/09/54443af8b86c85071ce9c09d80430b9a.webp)

![[Solving issues in the retail industry] Liquid freezing machines that should be introduced in supermarkets](https://shunkashutou.com/wp-content/uploads/2024/10/60172f0f261fd750c4016165c3c56cc8.webp)

![[Advantages and disadvantages of food additives] What is rapid freezer that solves the problems?](https://shunkashutou.com/wp-content/uploads/2018/11/ea1a552f8cb49685b3566dc4f06cf04b.webp)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[For food manufacturers] What is the meaning of IQF freezing and what is rapid freezer required for it?](https://shunkashutou.com/wp-content/uploads/2017/03/40008d9f1a752dd006399fe1c4beda34.jpg)

![[Government/local public bodies related] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_seihu_img_01.jpg)

![[Delicious food] Solving nursing home management issues with freezing and cooling technology](https://shunkashutou.com/wp-content/uploads/2024/08/7cabe275da8be8736f4496b952bde332.webp)