Dictionary of popular shock freezers! Read this to get the whole picture

A shock freezer that rapidly cools ingredients and foods and freezes them deliciously while preventing bacterial growth. However, because it is a highly specialized device, it is difficult to use it properly and to select the appropriate device. This page provides information about such shock freezers all at once. We will provide useful information for both first-time users and those who are already using the service.

目次

- 1What is a shock freezer?

- 2 Differences between shock freezer, blast chiller and freezer

- 3How to choose a commercial shock freezer without making any mistakes

- 4 Examples of how to use a shock freezer

- 5.I want to reduce costs...Is there a used item in such a case? none?

- 6 Introduction of recommended shock freezers

- 7 Conclusion

What is a shock freezer?

What is a shock freezer?

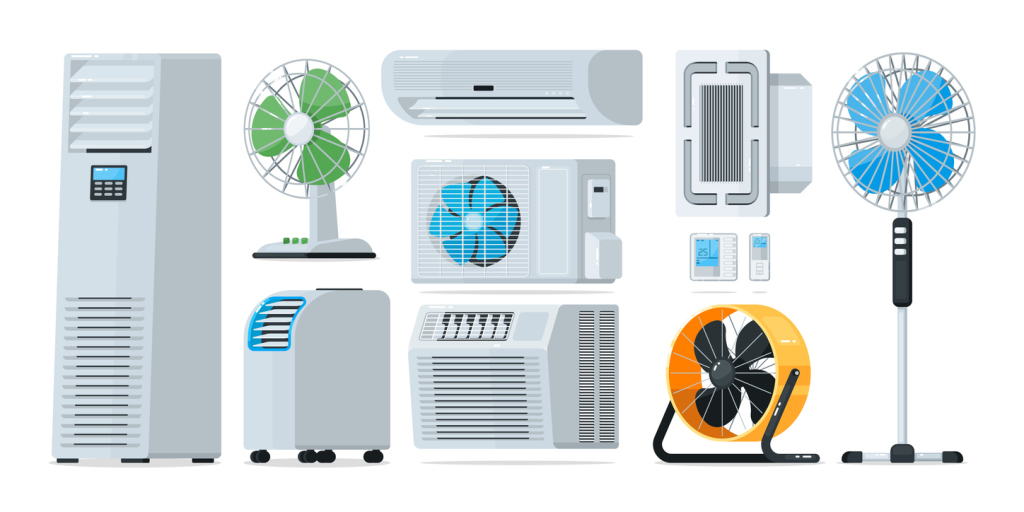

A shock freezer is a commercial-use refrigerator that is equipped with a rapid cooling mechanism to "suppress bacterial growth" and "improve freezing quality." They are called various names such as "rapid freezer," "deep rapid freezing," "flash freezer," "quick freezer," and "blast chiller," but they all refer to the same commercial rapid freezer.

Shock freezers work on the principle of rapidly cooling food by exposing it to air at a low temperature of -30℃ to -40℃.

The method that rapidly cools the air using low-temperature wind is called the "air blast method." Most shock freezers are air blast type.

Many products are sold under the name shock freezer/blast chiller, but strictly speaking, "freezer" and "chiller" are used for different purposes. Recently, there has been progress in miniaturization, and commercial shock freezers that run on 100V power have also appeared.

Although it is possible to quickly freeze small items, due to the way they work, they cannot cool many things, so you need to be careful when choosing one.

The price starts from 1 million yen for a small size, but if you consider that the size for commercial use is around 4 million yen, you will not be disappointed.

These products are also eligible for national and local government subsidies, tax deductions, and tax incentives, so they are recommended for those who are concerned about price.

Note! Shock freezers are surprisingly misunderstood

There is one point I would like to note here.

There is a widespread understanding in the world that "shock freezers are for quick freezing," but there are some misconceptions. Many shock freezers are designed for the purpose of "suppressing the growth of bacteria by rapidly lowering piping hot food to around 10 to 20 degrees Celsius using low-temperature cold air." In this case, the purpose is to cool rather than freeze, and there are many shock freezers that are not designed to the specifications necessary for "freezing".

Therefore, when considering the introduction of a shock freezer, we recommend that you check whether the equipment you are considering has specifications that are compatible with the freezing temperature range. We tend to pay attention to the specifications, such as how much the temperature will drop, but it is important to note that just because the temperature is low, it does not mean that the frozen quality will be high.

Shock freezers have become quite popular in recent years, but specialized knowledge is required to properly select and use them properly. Just putting ingredients and food into rapid freezing and calling it a day is not enough. There are many failures such as ``deterioration of frozen quality'' and ``deterioration of process efficiency'' due to half-hearted use, so be sure to learn about it. Let's make full use of it.

Difference between shock freezer, blast chiller and freezer

What's the difference between a shock freezer, a blast chiller, and a freezer?

In conclusion, both "shock freezer" and "blast chiller" refer to the same commercial rapid freezer. In other words, `` rapid freezer'', `` rapid freezing'', ``flash freezer'', and ``quick freezer'' are all the same.

Manufacturers do not differentiate between the two, and they are often sold under the product name ``shock freezer/blast chiller.''

However, as the names of Shock "Freezer" and Blast "Chiller" suggest, do they freeze (will the ending temperature be below 0°C) or will they cool (will the ending temperature be above 0°C)? ), and there are a certain number of people who use different words.

Therefore, it may be a good idea to call them shock freezers when the purpose is to freeze, and blast chillers when the purpose is to lower the temperature to the chilled zone.

In fact, some products sold as shock freezers/blast chillers are good at cooling but not good at freezing, so I think it's better to think about freezers and chillers separately. .

Also, the difference between a freezer and a freezer is often questioned, but both home freezers and commercial freezers, which are called "freezers" and "freezer stockers," are basically intended for storage by freezing. Freezers do not have the optimal structure for removing rough heat or freezing food. Cooling food in a regular freezer is called slow freezing, but the quality of many foods deteriorates due to slow freezing.

There are some ultra-low temperature freezers that can cool down to -60℃, but you need to be careful because just because the temperature is low does not mean it will freeze well.

Although it will cool faster if the temperature is lower than higher, the cooling speed will not be dramatically faster even at -60℃. Freezing speed is very important to improve freezing quality, but how to apply air is more important than low temperature in order to increase freezing speed. Freezers are made solely for the purpose of storage, so they are designed to prevent the generation of "wind" and are not designed to cool things down quickly.

Be sure to understand the differences between shock freezers, blast chillers, and freezers.

How to choose a commercial shock freezer without making any mistakes

Is it surprisingly difficult? Shock freezer selection

Next, we will explain how to select a shock freezer.

Shock freezers are often used for commercial purposes, so here we will explain how to select one for commercial use.

Shock freezers come in a variety of specifications depending on the application, from small ones the size of commercial freezers to large prefabricated ones.

Therefore, we recommend that you clarify several selection requirements in order to finalize the specifications as shown below.

The first thing that matters is the intended use. The optimal specifications will change depending on whether the purpose is "cooling (chiller)" or "freezing (freezing)", so the selection method will also change.

The next important consideration is what kind of food should be chilled. The way food is cooled varies greatly depending on its ingredients, shape, packaging, etc., and the specifications and functions required for a shock freezer also change. In addition, the temperature before cooling (chiller) and the temperature after cooling, or the temperature before freezing (freezing) and the temperature after freezing, are also important indicators.

And the last important indicator is "time".

Another important indicator is how much time is available for cooling and freezing. First, it is necessary to select equipment according to the production capacity of the pre- and post-processes. At that time, it is necessary to select equipment by considering how much time can be used for the cooling and freezing process.

In addition, production efficiency changes depending on how many minutes it takes to cool and freeze, so it is important to select appropriate specifications that take time into account.

For example, in the process of freezing hamburgers after baking, if □□ hamburgers are baked every XX minutes, it is necessary to select a shock freezer that matches the production capacity of the process. Additionally, if packaging is to be done in a post-process, it is also necessary to consider post-process production capacity, such as how many seconds the takt time is for one package in that packaging process.

The correct selection can only be made by clarifying the intended use, the object to be cooled, and the time required for the pre- and post-processes and cooling process.

The functions of a shock freezer (rapid freezer) are also very important, but first let's clarify the basic selection requirements.

When you consider these factors, it can be difficult just to come up with the selection requirements.

In that case, please take advantage of Daybreak's free phone consultation. Daybreak handles shock freezers with various principles and has a track record of more than 1,500 consultations a year.

Choose a shock freezer that suits your purpose!

The power of shock freezers varies depending on the specifications. Just as the engines of light cars and trucks have different power, shock freezers also have different engines for cooling.

The reason I mentioned earlier that the specifications differ depending on whether the purpose of use is cooling (chiller) or freezing (freezing) is because you have to make a selection that takes into account the power.

The power required for cooling is different between cooling (chiller) and freezing (freeze). (Refrigerating requires a larger engine because it uses more power to cool it.)

However, all manufacturers of shock freezers on sale are labeled as if they can do both "chilling" and "freezing". It is certainly possible to perform refrigeration using a chiller design, but this will reduce production efficiency and cost performance. It will be a waste to introduce it, so be conscious of choosing it according to your purpose.

Many shock freezers are designed with specifications for cooling (chiller), so be careful when purchasing one for freezing purposes.

Also, it is very important these days to consider whether the design meets hygiene management standards. In both cases of cooling and freezing, be sure to select equipment that complies with HACCP and the Hygiene Management Manual for Mass Cooking Facilities.

[Reference] Ministry of Health, Labor and Welfare’s hygiene management manual for mass cooking facilities

Foods other than foods that are served immediately after cooking must be kept at 10°C or lower or 65°C or higher to suppress the growth of food-poisoning bacteria. (See Attachment 3) ① When cooling food after cooking, use a cooling machine or Take measures to lower the core temperature to around 20°C within 30 minutes (or to around 10°C within 60 minutes) by dividing the medicine into sanitary containers in a clean place.

Of course, the way the shock freezer cools just one piping-hot item differs from the way it cools a large quantity. The more food you put in the shock freezer at once, the worse it will stay cold. If this happens and the engine power is not optimal, problems may occur such as not meeting HACCP and mass cooking facility hygiene management manuals. Non-compliance increases the risk of food poisoning, and if food poisoning occurs, the business will be suspended and the store's signboard will be damaged, resulting in huge losses.

If you ask me, it's obvious, but there are many cases of failure because this selection is not optimal, so be sure to consult with a mechanical professional before proceeding with your selection.

Click here for information on Art Lock Freezer

Examples of how to use a shock freezer

How to use a shock freezer?

There are two main ways to use a shock freezer. They are cooling (chiller) and freezing (freeze).

① "Cool" to prevent bacterial growth and for chilled distribution

┗ Cool food to suppress food-poisoning bacteria, as stipulated in HACCP and the Ministry of Health, Labor and Welfare's hygiene management manual for mass cooking facilities.

┗Cool foods that are eaten in the chilled temperature range, such as pudding and cake sponges. etc

② "rapid freezing with high quality" to produce frozen foods

┗Quick rapid freezing to prevent quality deterioration. etc

Most shock freezers use strong wind to quickly cool down food, which tends to cause dryness.

In addition, the surface is prone to discoloration and oxidation due to strong winds.

It is recommended to conduct thorough testing before implementation.

It is also important to choose a shock freezer that has a principle that prevents drying in the first place.

The operation itself is actually very simple. The process is to place the item you want to cool or freeze on a French baking tray (European baking tray), hotel pan, etc. and insert it.

Shock freezer usage examples

Shock freezers can provide various business benefits when used effectively.

If high-quality freezing can be achieved using a shock freezer, a variety of business developments can be expected.

We have put together an example of how to use it, so please use it as a reference.

View materials on rapid freezing

I want to keep costs down...is there a used item? none?

Can you save money by purchasing a used shock freezer?

The market for shock freezers is rapidly expanding, and there are many used products on the market.

It's an expensive device, so if you're going to install it, you'll want to do it cheaply. In such cases, second-hand items are very useful.

However, as I have explained above, shock freezers are highly specialized commercial equipment.

Therefore, if you are not familiar with maintenance, handling, usage, or the principles of refrigeration, it may be best to refrain from purchasing a used product.

In the case of second-hand equipment, there is the advantage of being able to purchase it at a lower price, but since it is equipment for commercial use, special parts and the dispatch of specialized engineers will be required if repairs need to be made. In industries like the automobile industry, where there are a large number of parts and engineers, repairs can be done at low cost, but in the shock freezer/blast chiller industry, the number of engineers is small and valuable, so repairs are expensive. There is a trend.

Additionally, in the case of second-hand products, it is often difficult to obtain repair parts (particularly for semiconductor parts whose specifications change frequently) if the model has already been discontinued by the manufacturer.

Considering these costs and risks, if you are unable to maintain the item yourself, it may be cheaper to choose a new item rather than a used item that you don't know how it was used.

However, the price is by no means cheap, so it is better to reduce the introduction cost and get a good deal by making effective use of national and local government subsidies, tax deductions, and tax incentives. Probably.

Introducing recommended shock freezers

Recommendedlatest shock freezer “Art Lock Freezer Series”

We would like to introduce you to the latest recommended shock freezers/blast chillers.

Artlock Freezer has various functions using the latest technology and is the latest shock freezer that is compatible with both "chiller" and "freeze".

Achieving high quality. New principle microwind system

Up until now, it has been thought that the faster the food cools, the better.

In order to cool down quickly, two things are necessary: ``increase the wind speed'' and ``lower the temperature to the maximum''.

This method can actually damage the ingredients, resulting in quality deterioration such as drying, oxidation, discoloration, and cracking.

For this reason, conventional shock freezers tend to have a negative impact on quality.

With the new principle micro-wind system, this "way of applying wind" has been completely changed. It has a new mechanism that increases the efficiency of cooling food without damaging it.

Eliminates inconsistencies within the warehouse, improving quality and efficiency

Additionally, the micro-wind system eliminates variations in quality due to location within the warehouse.

With conventional shock freezers, the cooling rate inevitably varies depending on the location.

Additionally, depending on the ingredients being added, it could take more than twice as long to process, which could reduce the efficiency of cooling and freezing.

Artlock freezers equipped with a micro-wind system can eliminate variations in quality depending on storage location and maximize time efficiency during cooling and freezing.

You can also freeze piping hot items! Anti-frost mechanism

Traditionally, shock freezers have been difficult to operate continuously due to frost formation.

If you put something piping hot that produces steam, frost will form, so you have to defrost it once every 2 to 3 hours, and it takes about an hour to defrost it and restart it. was.

The new Artlock freezer has a unique anti-frost mechanism that prevents frost from forming on the cooling section, eliminating the problems associated with conventional defrosting.

This enables continuous operation for long periods of time without defrosting work.

Conclusion

We have introduced information about shock freezers from various perspectives.

Although it is becoming common in the world, specialized knowledge is required to use it properly. If you have any concerns, please feel free to contact us.

At Daybreak Co., Ltd., we are able to select the optimal equipment and establish operations using data and know-how based on 1,500 consultations a year.

Please feel free to contact us.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Introducing trick techniques! ] How to freeze and thaw pancakes](https://shunkashutou.com/wp-content/uploads/2023/09/4f2e9d04709f0c4e5c1769985a49ac8b.jpg)

![[It's good to know! ] Introducing how to freeze curry, how long to keep it frozen, and how to thaw it |](https://shunkashutou.com/wp-content/uploads/2023/08/5de5495c896622dc896a8f23d9528300.jpg)

![[Delicious frozen foods] How to use them in lunch boxes, dinners, and snacks](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-1024x683-1.jpg)

![[Explanation with photos! ] How to freeze butter, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/08/4e4d4fde2efeae3d997d4356f1cc75c1.jpg)

![[Can it be frozen? ] How to freeze bacon, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/52dff5bc109cd400879fbf9bb35b3856.jpg)

![[Mass production and space saving] What is the secret of the spiral freezer structure?](https://shunkashutou.com/wp-content/uploads/2015/02/3d-sp.jpg)

![[Explanation of how to fry! ] Introducing how to freeze spring rolls and 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/8964429f347a4ffd32dca5809cd02100.jpg)

![[Can it be frozen? ] 5 recipes for yogurt freezing and shelf life!](https://shunkashutou.com/wp-content/uploads/2023/10/yogurt-catch-768x512-1.jpg)

![[Explanation with photos] How to freeze nagaimo, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/c46c238f2048d76de403dfd81ddad1f3.jpg)

![[Tips for making egg rolls that can be frozen] Introducing freezing methods, storage periods, and recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/tamagoyaki-768x512-1.jpg)

![Introducing how to freeze/thaw salmon roe and how long to store it [includes carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/09/236b884b68d07d2f5983f2b9ea66583d.jpg)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2016/06/09c17e4deeb1ac0cdc5a513eaf89ab1a.jpg)

![[Commercial rapid freezer] Explaining the features, size, and price of Panasonic rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/01/panasonic.jpg)

![[Explanation with photos! ] How to freeze green beans, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/f3dbbe5b1d05a50f514a833efdceced9.jpg)

![How to freeze chicken, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/01f6582931e13522ee0d1ee900be2d1d.jpg)

![Freezing garlic, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/30693b4b122ff6c57afff367b35bc861.jpg)

![[Convenient for lunch boxes! ] How to freeze fried noodles and 5 different recipes](https://shunkashutou.com/wp-content/uploads/2023/10/yakisoba-768x512-1.jpg)

![[Thorough Guide to Preserving Sweets] Introducing the freezing method, storage period, and thawing method in detail!](https://shunkashutou.com/wp-content/uploads/2023/10/bffcbc0b6e79bb1af6e05b930e11e949.jpg)

![[Explanation of how to fry! ] How to freeze and thaw pork cutlet, remake recipe!](https://shunkashutou.com/wp-content/uploads/2023/10/0a4143ad8ea0cc6bb6fdab8c74fab407.jpg)

![How to freeze potatoes and a great time-saving recipe! [Moms must see! ]](https://shunkashutou.com/wp-content/uploads/2023/10/potato1-768x512-1.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2016/03/661ea3ee6264fab6520017622c656870.jpg)

![[Explanation with photos! ] How to freeze pork, expiration date, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/8688cd28f298c3180c30169cec815293.jpg)

![[Explanation with photos! ] How to freeze taro, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/116858380_-768x512-1.jpg)