Case study of a profitable bento shop | The key to increasing profit margins is cost rate and planned production

Wouldn't you like to change the current situation where profit margins are declining due to rising food prices caused by rising prices of goods and increased hourly wages for part-time workers?

As those who already run a bento shop know, it is difficult to increase profit margins in a bento shop business where the unit price is low. In the worst case scenario, due to changes in circumstances such as rising prices, the business may become unsustainable and some may even go out of business.

However, it is also true that there are some bento shops that have succeeded in keeping their cost rates down and making a steady profit, even in these times of high prices and labor shortages, by taking important measures that many other bento shops have not yet implemented.

In this article, we will introduce some tips for making a solid profit at a bento shop, as well as a case study of a bento shop that increased its profit margin by 5% by taking certain measures and no longer has trouble recruiting staff.

This is a must-read for future bento shop owners and those considering opening one, as well as restaurant owners who want to expand their business by offering take-out and home delivery bento.

目次

- 1. Market trends of bento shops

- 2. Characteristics of bento shops

- 3. Profit structure of bento shops

- 4. Bento shop cost ratio

- 5 Three points to maximize profits at bento shops

- 6 Case study of a bento shop that achieved a 5% increase in operating profit margin by utilizing freezing technology

- 7. Benefits of using freezing technology and planned production system

- 8. rapid freezer solves the problems faced by bento shops

- 9 Summary

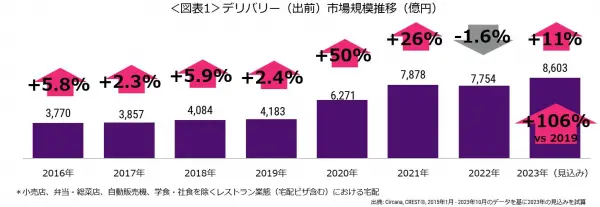

Market trends for bento shops

The Japanese bento market continues to grow steadily due to diversifying business formats and changing consumer needs. Busy working people and an increase in the number of single people are driving the expansion of the market, which is driving the demand for easy and healthy meals.

In particular, with the rise in health consciousness, companies offering high-quality bento boxes that focus on ingredients and cooking methods are attracting attention.

Some bento shops have been forced to go out of business due to rising raw material costs, but the fact that there is less competition means that it is still a business that is easier to succeed in if you can get into it by learning the tips and tricks for making a profit from a bento shop.

Characteristics of bento shops

There are many different types of bento shops, each with their own characteristics and advantages. To succeed in the bento business, it is very important to determine the target audience and the style in which to sell bento.

Store-provided

Since there is no need for space for eat-in seating, rent can be kept lower than that of a restaurant.

It is particularly important to understand customer needs, select store locations, and set appropriate prices.

Home delivery/delivery type

Although a manufacturing base is necessary, there is no need to worry about store location because delivery is the only option.

Also, since a simpler building is required than for a service-based store, rent and start-up costs can be kept low.

Kitchen car type

An initial investment in a truck equipped with cooking equipment and a road use permit are required. The ability to freely change the location of sales is a major advantage.

There are several sales methods, but selling bento boxes is an effective way for restaurants and other businesses to expand their business area and create new sources of income.

To start such a bento business, it is essential to select the best location, develop a menu that can differentiate you, and understand customer needs. Also, learning about the measures that bento shops that are already making a solid profit have taken and following their example will be a major point in making the business successful.

In the next chapter, we will look at the profit structure of a typical bento shop and specifically examine the measures necessary to improve profit margins.

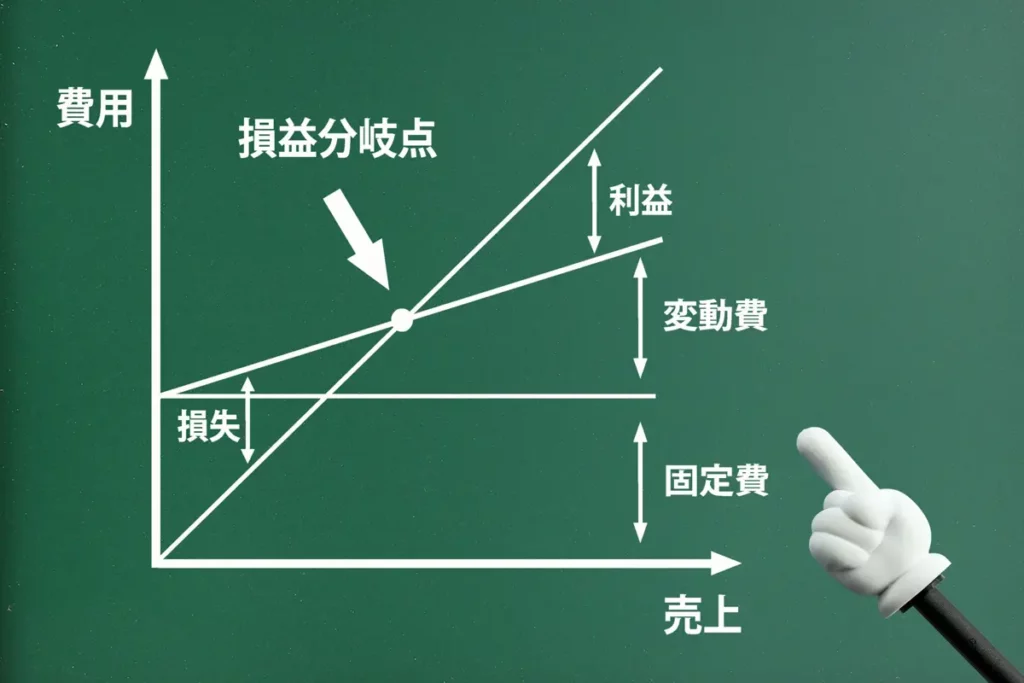

Bento shop profit structure

Monthly operating profit is calculated by subtracting monthly fixed costs and variable costs for lunch box ingredients from monthly sales.

[General business model (example)]

Sales: 1.08 million yen

Since bento shops are in the business of cooking ingredients, packaging them in containers and selling them, the majority of their expenses are made up of food costs. This is why keeping the cost rate of ingredients down is so important in order to increase profit margins.

Bento shop cost rate

The cost rate refers to the percentage of total sales that is accounted for by the cost of raw materials for the bento boxes.

If you want to make a good profit at a bento shop, it is ideal to keep this cost rate at around 35%, but

You can calculate the cost rate in the following way:

【原価率の計算方法】原価率(%)=原材料費➗売上✖️100

In recent years, due to rising raw material costs, it has become extremely difficult to maintain a cost ratio of 35%.

However, as you can see from the profit structure of a bento shop, the key to making the bento business successful is the cost rate, and bento shops that are actually profitable are able to use their ingenuity to keep their cost rates down and maximize their profits.

So how can you increase your profit margin like a successful bento shop?

Three points to maximize profits at bento shops

In order to make money and maximize profits at a bento shop, you need to take measures that are in line with the following points.

- Reduce the cost rate

- Reduce labor costs

- Increase sales

I will explain in detail how you can improve these three points.

Reduce the cost rate

First of all, given that raw material costs are rising, it is necessary to purchase ingredients as cheaply as possible.

There are ways to do this, such as finding cheaper suppliers and using seasonal ingredients that are cheap and readily available. In addition, you should be thorough in storing and managing the ingredients you purchase, so as to minimize food waste.

Reduce labor costs

Because bento shops need to start preparations early in the morning and maintain strict hygiene standards, many of them are experiencing serious labor shortages.

With limited manpower and daily production volume, a major challenge in increasing the upper limit on the number of meals that can be sold per day and boosting sales is how to improve production efficiency relative to working hours.

If you can improve your business operations, such as by using frozen work-in-progress to shorten the time required for cooking and preparation, you can reduce the time and labor costs required for production.

Increase sales

First of all, a bento shop's sales are proportional to the number of meals sold, so there are several possible measures to increase sales.

If you want to acquire new customers, you can use social media, which can attract customers effectively without spending money, to increase the awareness of your store. In addition, bento shops generally produce to order, so there is a limit to the number of items they can sell in a day. Even if you can predict the busy season to some extent, it is important to prevent loss of sales opportunities, such as responding to sudden large orders.

Another option is to segment your sales targets.

For example, if you are able to develop menus and attract customers that target the elderly and health-conscious, you may be able to set a higher price while keeping the volume of your bento boxes down, which may enable you to increase your sales efficiently.

Furthermore, if you aim to enter the higher-priced lunch box business, such as catering for conferences or high-end home delivery of lunch boxes, you can achieve stable sales at a high unit price even with limited sales numbers.

The business model of bento shops is to cook ingredients and pack them into containers. In order to maximize profit margins as a profitable bento shop, the cost rate of ingredients, which is a variable cost, is the key to success.

However, in the bento business, where the majority of expenses are made up of food ingredients, achieving a cost ratio of 35% requires a great deal of effort, and it is extremely difficult to lower that cost ratio.

As mentioned at the beginning, successful bento shops across the country are using various methods to reduce their cost rates and develop bento businesses that steadily increase their profit margins.

In particular, Shokutakubin, which is expanding its lunch delivery business targeting the elderly in response to the rapid aging of society, and RISE Co., Ltd., which operates a high-priced, high-end lunch delivery business, are using freezing technology in their lunch business to plan the production of lunches and achieve overwhelming production efficiency.

In the next chapter, we will introduce the case of RISE Co., Ltd. as a successful example of the bento business.

Case study of a bento shop that achieved a 5% increase in operating profit margin by utilizing freezing technology

RISE Co., Ltd. is a high-end lunch delivery service with a central kitchen in Osaka.

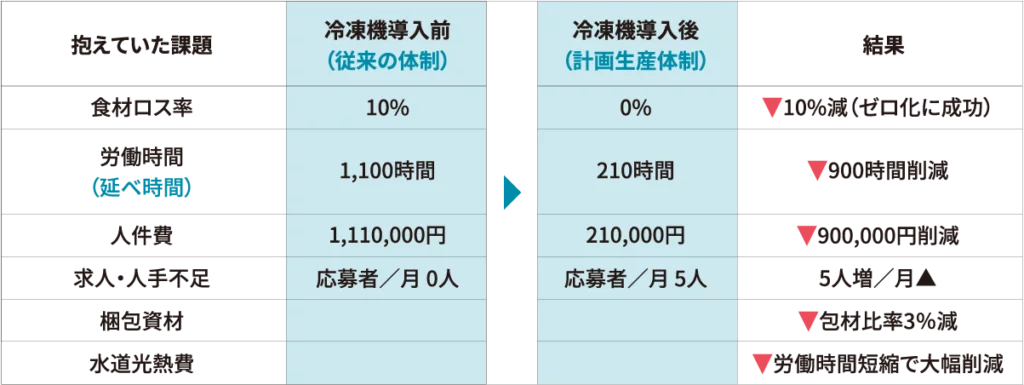

With the sudden drop in sales due to the COVID-19 pandemic, we introduced rapid freezer to improve the working environment and rebuild the business. Before the installation, we prepared all the lunch boxes early in the morning, but by being able to freeze and store the prepared foods we produced in large quantities during the day, we were able to establish a planned production system for the lunch boxes.

If planned production becomes possible in the bento business, which is basically made to order, it will be a revolutionary method that can solve the problems faced by many bento shops from multiple angles.

In the next section, we will explain the benefits of using freezing technology to build a planned production system in the bento business.

Benefits of using freezing technology and planned production system

Reduce late-night and early-morning work

Before RISE Co., Ltd. introduced rapid freezer, employees were burdened by late-night and early-morning work related to preparation. However, by changing the operation to freeze prepared food during the day and then thawing and shipping it when needed, the working environment has improved significantly.

Eliminating labor shortages

By shifting to daytime work, the hiring conditions have improved and it has become easier to acquire high-quality personnel. In addition, labor costs have been reduced by eliminating the need for night shift allowances. Since we can plan ahead and handle large lots and sudden orders during busy periods, labor costs associated with limited-term employment are no longer necessary.

Overwhelming production efficiency

By being able to freeze and store the prepared foods used in bento boxes and manage them as inventory, we have been able to reduce the food waste that previously occurred to zero.

In the case of RISE Co., Ltd., by using lunch box containers that can be assembled into parts, it is possible to produce all kinds of lunch boxes by simply combining frozen side dish parts with rice and main dishes to be produced on the day, and they have succeeded in achieving overwhelming production efficiency even with a small number of people.

[Issues improved through planned production system]

By introducing rapid freezer, RISE Co., Ltd. was able to improve its working environment in many ways, including reducing food and labor costs, resolving labor shortages, and increasing work efficiency. As a result, the company was able to increase its operating profit margin by 5% compared to before the introduction of the machine.

If you are interested in more detailed information about the case, please see the documents below.

rapid freezer solves the problems faced by bento shops

As mentioned in the case study, rapid freezer was introduced by a successful bento shop. We will explain in detail what benefits it actually has and how it can solve the challenges that bento shops face.

What is rapid freezer?

rapid freezer is a freezer that freezes food much more quickly than slow freezing, allowing it to be frozen and preserved at a high quality without destroying the food's cells.

Freezing technology, which can preserve ingredients and foods in high quality, extends the shelf life of ingredients and foods, allowing them to be stored in stock while remaining fresh.

What kind of changes will it bring to bento shops when it becomes possible to store food for long periods of time and to create a planned production system for bento businesses?

Reduce the cost rate

By freezing food, it is possible to preserve raw vegetables, fruits, meat and fish for much longer than the traditional expiration date. rapid freezing prevents the quality of food from deteriorating much more than slow freezing, and reproduces the color, flavor and texture of freshly picked food when thawed.

In addition, ingredients purchased in large quantities during cheap periods can be managed as inventory, preventing food waste and making it easier to keep costs down.

Can reduce labor costs

Since the sale of food products with expiration dates, such as bento boxes, is generally made to order, production in a day is usually limited to the amount that will be sold that day.

However, if food can be frozen to a high quality, it is possible to plan and produce the amount to be sold the next day or later during the day and store the food in stock.

This will enable a significant reduction in work hours and improve work efficiency, resulting in reduced labor costs.

Improving working conditions

As mentioned earlier, improving production efficiency through the use of freezing technology can result in significant reductions in labor hours.

A significant reduction in working hours will lead to reduced manufacturing costs such as labor and utility costs, and it will also make it easier for employees to take time off. Furthermore, an improved working environment will lead to better employment conditions and make it easier to recruit, which will help alleviate labor shortages.

Expanding trade area

By utilizing technology that allows food to be frozen while maintaining its quality, customers far away who are unable to visit stores can enjoy the taste of freshly made food through mail order and wholesale.

This will also lead to increased sales by increasing awareness of the bento brand and expanding the business area.

Reasons to choose ART ROCK FREEZER

There are several types of rapid freezer, and it is very important to choose the most suitable model according to production volume and ingredients to be frozen.

For the bento shop business model, we recommend Art Lock freezers, which have a large market share and are highly skilled at freezing multiple ingredients to high quality.

Here are some reasons why ART Lock Freezers are ideal for bento shops.

Overwhelmingly high freezing quality

The Art Lock Freezer uses a special fan to create fine cold air that prevents ingredients from drying out, and can freeze food faster than ordinary rapid freezer.

Food can become dehydrated when exposed to strong cold air, and the longer it takes to freeze, the more the quality deteriorates. By using gentle air to prevent drying and freeze quickly, quality deterioration can be prevented and the food can be frozen while maintaining its high quality.

Incredibly high productivity

Art lock freezers have an interior design that makes it difficult for frost to form, so there is no need to stop operation of the machine as with conventional defrosting.

What's more, the AI installed in the machine adjusts the electricity and power required for cooling, so it operates fully automatically and efficiently to freeze the ingredients inside as quickly as possible.

This allows for overwhelming increases in productivity by allowing production to continue without interrupting operations.

Incredible ease of operation

Art Lock Freezers freeze food automatically just by placing the food inside and closing the door. The built-in sensor detects the condition inside the freezer and notifies you beforehand of any abnormalities caused by overfilling the freezer or operating it improperly. It is also chosen for its ease of operation, which makes it easy to use even for people without special knowledge or skills.

Incredibly high cost performance

Our strengths are our technology that enables high-quality, speedy freezing processing, functions to keep the machines running, and ease of operation that allows anyone to operate the machines with full automation and efficient, optimal operation.

These ART Lock freezers offer a good balance of functionality, productivity, and operation, and are rapid freezer that deliver high performance, which is why they are chosen by many companies.

Conclusion

I learned that the key to making a profit at a bento shop is to (1) reduce labor costs, (2) increase sales, and (3) reduce the cost rate.

It is difficult to reduce the cost rate, but by introducing rapid freezer and establishing a planned production system for bento boxes, issues with labor costs, sales, and cost rates can be resolved.

Among rapid freezer that are a revolutionary solution for the boxed lunch business, the Art Lock Freezer boasts high functionality and freezing quality, and demonstrates high cost performance by maximizing productivity.

If you want to make your bento business a success, or if you are interested in rapid freezing as a solution to problems in restaurant management, please contact us now.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Increase sales! ] Three reasons why ramen restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/08/deb66347f085932482279d9069d398c8.webp)

![[Freezing boiled food] rapid freezing demo](https://shunkashutou.com/wp-content/uploads/2016/10/4739208abfe6e2e63a43347c1598e991.webp)

![[Can it be frozen? ] How to freeze mashed potatoes, how long they can be stored, and how to use them](https://shunkashutou.com/wp-content/uploads/2023/09/b7f3f25102051473b7c2f9452840a6f4.jpg)

![[Secret Technique] Introducing the freezing preservation and remake recipe of Kinpira Burdock!](https://shunkashutou.com/wp-content/uploads/2023/09/4c4b704274331befeed83cc4493acb75-1.jpg)

![[Osechi remake dishes too! ] Introducing the method and recipe for freezing black beans](https://shunkashutou.com/wp-content/uploads/2023/09/9bcd5b0667eef32b7c7daf786e01172f.jpg)

![[Lunch boxes are easy! ] Techniques and recipes for effectively using frozen side dishes](https://shunkashutou.com/wp-content/uploads/2023/07/reitou-bento-1024x682-1.jpg)

![[Freezing pickles] rapid freezing demo](https://shunkashutou.com/wp-content/uploads/2016/09/54443af8b86c85071ce9c09d80430b9a.webp)

![[Be good at saving money! ] Introducing the method and recipe for freezing fried rice](https://shunkashutou.com/wp-content/uploads/2023/10/mayo-tyahan-1024x768-1.jpg)

![[Explanation with photos] How to freeze meat sauce, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/efa7161a08e57ef763d9e19623c7669c.jpg)

![[It's good to know! ] Introducing how to freeze curry, how long to keep it frozen, and how to thaw it |](https://shunkashutou.com/wp-content/uploads/2023/08/5de5495c896622dc896a8f23d9528300.jpg)

![[Can it be frozen? ] How to freeze dried daikon radish and arrange recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/84f89f802d6869949972432e7b3be19c.jpg)

![[Can it be frozen? ] Introducing the recipe and how to freeze potato salad!](https://shunkashutou.com/wp-content/uploads/2023/10/3c640cd23d65764c14f701d25970ed59.jpg)

![[Explanation with photos! ] How to freeze and fry croquettes, 5 carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/09/b364ee97a71777f9dd2e35fddbbdda72.jpg)

![[Explanation with photos! ] How to freeze hijiki and its storage period, 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/ff6bdc527dd066b7d725a48161d7925d.jpg)

![[Freezing Neapolitan] rapid freezing demonstration](https://shunkashutou.com/wp-content/uploads/2016/09/napolitan.jpg)

![[Restaurants/Restaurant] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/inshoku-article-eyecatch1.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![[Thorough Guide to Preserving Sweets] Introducing the freezing method, storage period, and thawing method in detail!](https://shunkashutou.com/wp-content/uploads/2023/10/bffcbc0b6e79bb1af6e05b930e11e949.jpg)

![[Rapid defrosting or slow defrosting] Unsure of which method? Read the complete guide on how to defrost](https://shunkashutou.com/wp-content/uploads/2024/10/ec8d0eb82bcecb5525574a8f72183a97.webp)

![[Achieving low cost and high quality] The problems of pubs can be solved with a quick freezer!](https://shunkashutou.com/wp-content/uploads/2024/09/11d55612344a4cbad2ad506ae700c81b.webp)

![[Introduced one after another in restaurants] Advantages of commercial rapid freezing! What about second hand ones?](https://shunkashutou.com/wp-content/uploads/2015/05/16920085ea8194572cc7c5babebedbe5_s.jpg)

![[Must-see for bakers] 6 reasons why bakeries should use rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/02/f92a102c9d3cc8c63dc7e509ce6d35d2.jpg)

![[Tips for making egg rolls that can be frozen] Introducing freezing methods, storage periods, and recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/tamagoyaki-768x512-1.jpg)

![[Recover the machine cost in about 1 year! ]Reduce loss of tiger puffer fish with rapid freezing!](https://shunkashutou.com/wp-content/uploads/2018/07/1772bacb83f79fbd476ca3d66c8f8281_s1.jpg)

![[Can it be frozen? ] How to freeze and thaw okonomiyaki, arrangement recipe!](https://shunkashutou.com/wp-content/uploads/2024/01/58bc763c02f23a2a6442d6449853a67b.jpg)

![[Introducing tricks and time-saving techniques! ] How to freeze ginger-yaki, carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/10/ef145c31655c5774469e05b5e892207b.jpg)

![[Recommended for making lunch boxes! ] Delicious ways to use frozen foods](https://shunkashutou.com/wp-content/uploads/2023/09/m-frozen-food-bento_eyecatch.jpg)

![[For the lunch box manufacturing industry] Business issues can be solved by using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/04/f93f171f5d29bdb15c4b8d06e244b002.jpg)

![[Solving issues in the retail industry] Liquid freezing machines that should be introduced in supermarkets](https://shunkashutou.com/wp-content/uploads/2024/10/60172f0f261fd750c4016165c3c56cc8.webp)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2024/08/09c17e4deeb1ac0cdc5a513eaf89ab1a.webp)

![[How long does frozen fish and meat last? ] Interesting expiration dates and tips to extend the shelf life](https://shunkashutou.com/wp-content/uploads/2023/08/f124221382987fe32d0ffda6b6f497c1.jpg)

![[Freshly made raw soba all over the country! ] Example of introducing a quick freezer at a soba restaurant](https://shunkashutou.com/wp-content/uploads/2024/09/6d8138adcf26c410c11b25d5b8d2f3de.webp)