Explanation of the advantages, disadvantages, prices, and cost-effective introduction methods of liquid freezing machines!

"Liquid freezing machines" have been attracting attention in recent years.

By freezing high-quality foods, you can preserve them for long periods of time without sacrificing their quality.

Various manufacturers offer products and information regarding such liquid freezers, and it is extremely difficult to select the most suitable product.

Therefore, on this page, we will introduce information about liquid freezers, including their advantages and disadvantages, points to note when choosing, and prices.

We will also provide information on subsidies and other information that can help reduce costs when implementing the system, so please read until the end.

目次

- 1What is a liquid freezing machine (alcohol freezing machine)?

- 2 Advantages of liquid freezing machine

- 3Disadvantages of liquid freezing machine

- 4How to select a liquid freezer

- 5 Recommended is Rejoice Freezer (Manufacturer: Yoneda Koki Co., Ltd.)

- 6 liquid freezing machine price

- 7It is recommended to purchase a liquid freezer with a subsidy.

- 8 summary

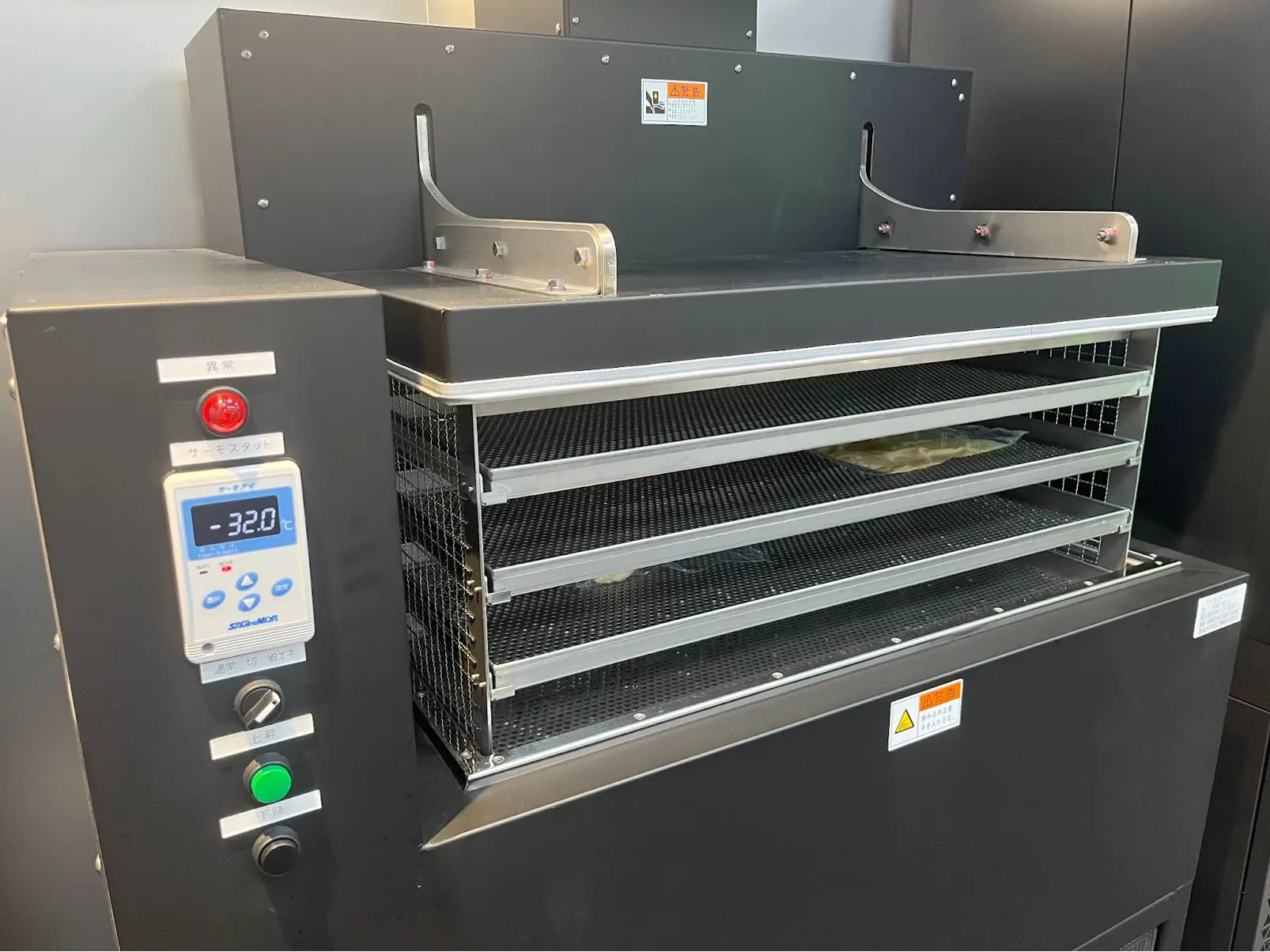

What is a liquid freezer (alcohol freezer)?

A liquid freezer is a type of rapid freezer that freezes food by immersing it in a liquid that has been cooled to -10℃ to -35℃.

Liquids have an extremely high thermal conductivity (temperature transmission efficiency) of approximately 20 times that of air, so they freeze very quickly and can be frozen without damaging cells. By minimizing the amount of drips during thawing, you can prevent the loss of flavor and nutrients and maintain the flavor, taste, and color of the food.

The liquid used is something called antifreeze, which does not freeze even at operating temperatures (-10°C to -35°C). Many liquid freezers use alcohol as an antifreeze due to availability and cost, and these rapid freezer are also called "alcohol freezers" or "alcohol freezers."

Currently, there are two types of rapid freezer: the liquid freezing type and the air freezing type, which cools by applying air.

Advantages of liquid freezing machine

What advantages does a liquid freezer have compared to other freezers?

Here we will introduce three advantages of liquid freezing machines.

Advantage 1: High quality

The first advantage of liquid freezers is their high quality.

Liquid freezers freeze foods without destroying their cells, so they can maintain the quality of a variety of foods such as meat, fish, and side dishes.

・Development of new frozen foods

・Providing inexpensive, high-quality seasonal ingredients throughout the year

・Eliminate labor shortages by freezing food in advance for busy seasons

It is also possible to create effects such as

Advantage 2: Fast freezing speed

The second advantage of a liquid freezer is its fast freezing speed.

A liquid freezer has a thermal conductivity 20 times that of air, so when compared under the same conditions, the freezing speed is particularly fast.

In particular, for foods that take time to freeze, such as thick blocks of meat, production efficiency can be increased by shortening the freezing time.

Advantage 3: Comprehensive lineup of small types

The third advantage of liquid freezing machines is that they have a rich lineup of small equipment.

Currently, the most popular air freezing type requires a large engine, so even the smallest model requires a certain amount of installation space.

On the other hand, the liquid freezing type uses liquid to store cold, so there is also a small lineup that does not take up much installation space.

You need to be careful because the smaller the size, the less amount you can freeze, but if you can freeze the required amount, you can install a smaller model.

There are also models that operate on the same 100V power supply as home freezers.

Disadvantages of liquid freezers

So far, we have introduced the advantages of liquid freezing machines.

However, there are some disadvantages that you should be aware of when installing a liquid freezer.

Disadvantage ①: Requires vacuum packaging

The first disadvantage of liquid freezers is that they require vacuum packaging.

In the case of a liquid freezer, the food is soaked in an antifreeze solution such as alcohol (hereinafter referred to as alcohol), so the food must be vacuum packed before freezing.

It is possible to deaerate the bag and freeze it in air-filled packaging, but the air remaining in the vacuum bag acts as insulation, slowing down the freezing speed. It is not recommended to freeze the product while it contains air, as this can cause quality deterioration.

Liquid freezers basically require vacuum packaging, so the three patterns we will introduce below are not suitable for liquid freezers.

[In case of deterioration due to vacuum packaging]

Foods that deteriorate when vacuum packed will lose their quality when frozen, making it difficult to maintain quality with a liquid freezer.

It is especially difficult to maintain the quality of foods such as cakes and rice that collapse when vacuum packed.

[If you want to freeze individual pieces (IQF freezing)]

If you freeze vacuum-packed food, the food will remain stuck together inside the vacuum bag.

Therefore, it is not possible to produce products such as sliced meat or seafood mixes in which the ingredients are frozen in pieces and then thawed in the desired amount using a liquid freezer.

[When freezing sharp products]

Sharp items such as shrimp, crab, fish bones, and the corners of bento boxes that are frozen with food may leave holes in the vacuum bag.

If you soak the vacuum bag in alcohol with holes in it, the alcohol will get mixed in, making it unusable and resulting in product loss.

If the food you are handling falls under these conditions, we do not recommend freezing it in a liquid freezer.

In that case, we recommend the latest air freezing type rapid freezer. The freezing speed is very fast while preventing drying, so you can freeze ingredients naked.

Disadvantage ②: Risk of complaints occurs

The second disadvantage of liquid freezing machines is the risk of complaints.

As mentioned in Disadvantage 1, liquid freezers can leave holes in the vacuum bag, allowing alcohol to get mixed in.

At that time, there are many cases in which a small amount of alcohol is not noticed even when visually inspected, and the product is passed on to customers.

The alcohol used in liquid freezers has a controlled concentration and often has a strong bitter taste when put into the mouth, leading to complaints if the taste is obviously off.

Food manufacturers and food processing manufacturers tend to avoid liquid freezers due to the risk of complaints like this.

Disadvantage ③: Lots of work (man-hours)

The third disadvantage of a liquid freezer is that it requires a lot of work (man-hours) for freezing.

When you remove the frozen product from the liquid freezer, the vacuum bag will have alcohol attached to it.

If left as is, the inside of the storage room will be covered with alcohol, and the items will get soaked when wrapped and packaged, so you will need to drain and wipe the alcohol off.

Please be careful as it is difficult and time consuming to wipe off the frozen cold alcohol one by one.

Disadvantage ④: Running cost is expensive

The fourth disadvantage of liquid freezers is that running costs are relatively high.

In addition to the electricity costs normally incurred, in the case of a liquid freezer, special attention must be paid to other costs such as ``alcohol costs'' and ``labor costs.''

[Alcohol cost]

Alcohol decreases as the ingredients are frozen, so you will need to replenish that amount. Depending on the product and operation, it costs approximately 60 to 70 yen for alcohol to freeze 10 kg.

[Personnel costs]

As explained in Disadvantage 2, liquid freezing machines require the work of draining and wiping off the alcohol after freezing the product.

The costs unique to liquid freezing machines are often not taken into consideration until they are installed, but it is said that the labor costs associated with this work are the largest in running costs.

ーーーーーーー

If 30 kg is frozen every day for 1 year (20 days of operation x 12 months)

Draining and wiping 30kg of product: 60 minutes

Check the product for pinholes: 10 minutes

Personnel costs for 1 hour (hourly wage for part-time workers: 1,000 yen + 30% recruitment and management costs for part-time workers)

Draining and wiping 30kg of liquid...1,300 yen

×20 days

×12 months

→364,000 yen for 1 year

ーーーーーーー

In this way, running costs are higher for liquid freezing types compared to air freezing types.

When freezing large chunks of food, such as blocks of meat, some people choose to use a liquid freezer because it requires less draining and wiping.

However, when it comes to freezing other products that require time-consuming draining and wiping, the current situation is that air freezing types are far more popular than liquid freezing machines.

Artlock Freezer, the latest air freezing machine, has improved quality and capacity, achieving the highest level of quality ever and cost-effective production.

As explained above, while liquid freezing machines have advantages, they also have disadvantages. Consider the advantages and disadvantages when choosing rapid freezer.

How to choose a liquid freezer

Although there are various manufacturers, models, and products of the liquid freezing machines that we have introduced so far, many people may not know which one is best for them.

Here we will introduce two important points when choosing a liquid freezer.

① Freezing processing amount (power/liquid amount)

When choosing a freezer for everyday use, you choose it based on the internal capacity (liters), but when it comes to rapid freezer, many people fail in this selection process.

A liquid freezer is equipment for freezing. Therefore, it is important to know how much food you can freeze. If you choose a freezer with a small freezing capacity for the amount you want to freeze, you may not be able to freeze the food completely or the frozen quality may deteriorate significantly.

The cause is that the temperature of the alcohol rises. When food is soaked in alcohol, the alcohol takes away the temperature of the food, and the temperature of the alcohol increases instead. The higher the temperature of the alcohol, the slower the freezing speed will be, making it impossible to freeze the food.

Therefore, it is recommended to compare liquid freezers based on two criteria: the power of the freezer, which is related to its ability to lower the temperature of alcohol, and the amount of alcohol, which is related to how easily the temperature of alcohol rises when food is pickled.

[Power of refrigerator]

A liquid freezer has a part called the refrigerator, which is the engine of the machine, and uses the power of that engine to lower the temperature of the liquid (alcohol).

The stronger the power, the higher the ability to cool alcohol, so even if you put a lot of food in alcohol and the temperature rises, it will quickly cool down, allowing you to freeze more food.

[Amount of alcohol]

In a liquid freezer, the alcohol cooled to a low temperature by the refrigerator engine removes heat from the food to freeze it.

At this time, the temperature of the alcohol that has taken away the heat rises by the amount of heat taken away.

Therefore, the higher the amount of alcohol at a lower temperature, the more heat can be taken from the food, but the amount of alcohol that can be put in differs depending on the liquid freezer model.

The more alcohol you have, the more energy you can store for cooling, making it harder for the alcohol to heat up when you put food in it.

For example, the temperature will not rise more if you pour 1 liter of hot water into 10 liters of water than by pouring 1 liter of hot water into 2 liters of water.

Therefore, liquid freezers that contain more alcohol, an antifreeze, can freeze a larger amount at one time and can operate continuously for longer periods of time.

②Automatic lift type/manual type

There are two types of liquid freezers: manual type and automatic lift type.

・Manual type

The manual type is a type in which food is placed in a basket and placed in and taken out of the liquid freezer by hand.

・Automatic lift type

The automatic lift type is a type in which the part that feeds food into the liquid freezer is mechanical.

If the product is small, send it to a liquid freezer.

There are no particular problems when loading and unloading items, but loading and unloading items weighing 10 to 20 kg into the basket is a heavy task, which is difficult for women and elderly people to do.

Therefore, if you want to freeze more than a certain amount, it is recommended to install an automatic lifting type liquid freezer for safety and workability.

Rejoice freezer is recommended (manufacturer: Yoneda Koki Co., Ltd.)

Up to this point, we have explained the points to consider when selecting a liquid freezer.

So, if you decide to install a liquid freezer, which manufacturer's product is best?

If you are planning to install a liquid freezer, we recommend the Rejoice Freezer (manufacturer: Yoneda Koki Co., Ltd.).

Yoneda Koki not only handles liquid freezing machines, but also other production equipment, and is a company with advanced technology that can custom-make products to suit the company that installs the equipment.

Compared to other manufacturers, liquid freezers have higher cost performance (higher freezing capacity relative to price), and because they can hold a large amount of liquid inside the refrigerator, they can be operated continuously or handle a large amount of food at once. Can be frozen.

In addition, all models other than the small model (1 to 3 kg/h) are of the automatic lifting type, making them safe and easy-to-operate liquid freezing machines for anyone.

liquid freezing machine price

The price of a liquid freezer varies greatly depending on the size and specifications, and also varies slightly depending on the location and delivery/installation conditions.

The larger the freezing processing capacity (the amount that can be frozen per hour), the higher the price, so it is recommended to consider performance and price and install an appropriately sized liquid freezer.

Currently, the smallest liquid freezing machines start at around 1 million yen.

It is recommended to purchase a liquid freezer with a subsidy.

As I have explained so far, liquid freezers are not cheap purchases.

For this reason, some people purchase with cash, but there are also many who use subsidies and tax breaks to purchase at a good price, or use leases to reduce initial costs.

When utilizing subsidies, particularly recommended are ``Business Restructuring Subsidies'' and ``Manufacturing Subsidies.'' The subsidy amount is large, ranging from 1 million yen to 100 million yen, and the subsidy rate is very high, with a maximum of 2/3 subsidy.

In addition, there are many cases where liquid freezers are introduced using subsidies from prefectures, municipalities, etc.

For more information, please contact us and our professional staff will introduce you to us.

We also offer a service that prepares all the necessary documents when applying for a subsidy. If you would like to apply but don't have the time, or if you would like to outsource the troublesome work, please contact us.

Conclusion

What did you think?

Liquid freezers can freeze food without compromising its quality.

However, as there are compatibility issues with the ingredients, we recommend conducting an actual freezing test before selecting equipment.

There are also ways to introduce it at a discount using subsidies.

If you are considering installing a refrigerator, please feel free to contact us.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Solving issues in the retail industry] Liquid freezing machines that should be introduced in supermarkets](https://shunkashutou.com/wp-content/uploads/2024/10/60172f0f261fd750c4016165c3c56cc8.webp)

![[Great at sushi restaurants! ] How to increase sales by rapid freezing sushi](https://shunkashutou.com/wp-content/uploads/2016/04/0d3e7f8a3cefa0aefe0a8452e414db21.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2024/09/661ea3ee6264fab6520017622c656870.webp)

![[Rapid freezers in 2021] Market Trends and Customer Success Stories](https://shunkashutou.com/wp-content/uploads/2020/12/7F9A9CB9-A494-4E6A-946E-079279C596E6.jpeg)

![[Make frozen oysters even more delicious! ] Correct thawing method and usage recipes](https://shunkashutou.com/wp-content/uploads/2023/10/5855c6e6d6dbdb298f86405b4b522329.jpg)

![[Commercial rapid freezer] Explaining the features, size, and price of Panasonic rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/01/panasonic.jpg)

![[For maintaining food quality!] Three functions you should know about constant temperature and high humidity storage](https://shunkashutou.com/wp-content/uploads/2015/10/krefrigerator.jpg)

![[Required for food business operators] What is the reason for implementing HACCP and using rapid freezing?](https://shunkashutou.com/wp-content/uploads/2017/02/b9dcd4b8ff706013bae4aafeda989b6e.jpg)

![[Rapid defrosting or slow defrosting] Unsure of which method? Read the complete guide on how to defrost](https://shunkashutou.com/wp-content/uploads/2024/10/ec8d0eb82bcecb5525574a8f72183a97.webp)

![[Must-see for bakers] 6 reasons why bakeries should use rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/02/f92a102c9d3cc8c63dc7e509ce6d35d2.jpg)

![[Food/processing manufacturers] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_kakou_img_01.jpg)

![[Achieving low cost and high quality] The problems of pubs can be solved with a quick freezer!](https://shunkashutou.com/wp-content/uploads/2024/09/11d55612344a4cbad2ad506ae700c81b.webp)

![[Easy thawing method] Low temperature thawing to lock in the deliciousness of meat](https://shunkashutou.com/wp-content/uploads/2024/08/899e71a518bbd73569bf085ff0accd61.webp)

![[Is it actually something familiar? ! ] Types of flash freezing and their temperatures](https://shunkashutou.com/wp-content/uploads/2024/10/c4fc26caaee432beead8d55028903079.webp)

![[Safely distribute delicious fish! ] Kill Anisakis with rapid freezing technology!](https://shunkashutou.com/wp-content/uploads/2024/10/99093c5fe8b0d716c39df907616e4a96.webp)