Measures for waste loss and expiration dates in food manufacturing

The current situation in Japan is that food waste amounts to millions of tons each year.

In particular, waste in the food manufacturing industry has a large impact on the environment and the economy and society, and is an issue that the entire food industry must address.

In this article, we will touch on the causes of waste in the food manufacturing industry and introduce measures to reduce waste.

There are also cases where companies have focused on expiration dates, which can be said to be the fundamental reason for waste, and have achieved significant reductions in waste. We would like to introduce one example of this as a reference for efforts to reduce waste.

目次

- 1. What is waste loss in the food manufacturing industry?

- 2. Current state of waste in the food manufacturing industry

- 3. Impact of waste on the social environment

- 4 Main causes of waste in food production

- 5 Benefits of reducing waste for food manufacturing companies

- 6 Measures to reduce waste in the food manufacturing industry

- 7. Measures to address expiration dates, which are the root cause of waste

- 8 Examples of using rapid freezing technology

- 9 Features of Art Lock Freezer

- 10. What is rapid freezing, which allows long-term storage without compromising quality?

- 11 Benefits of rapid freezing

- 12 Reasons to choose ART Lock Freezer

- 13 Summary

What is waste loss in the food manufacturing industry?

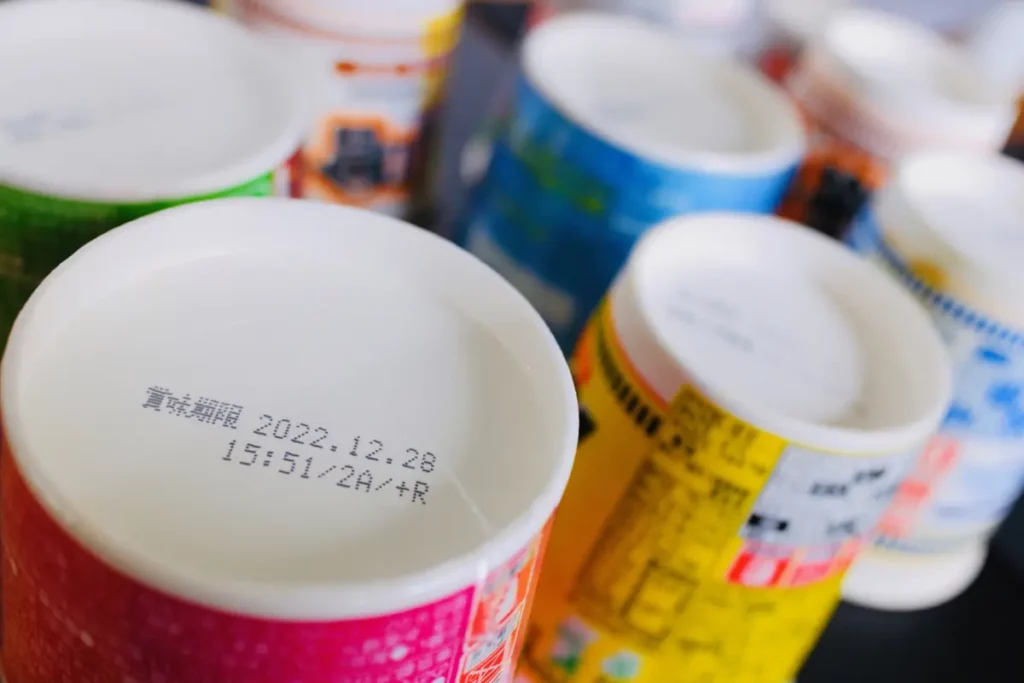

In the food manufacturing industry, waste loss refers to the loss incurred when products are over-purchased and then discounted or discarded due to exceeding the product's quality retention period (best-before date, expiry date, etc.). When discarding inventory, not only are disposal costs incurred, but the costs incurred in purchasing and inventory management are also wasted.

The current state of waste in the food manufacturing industry

According to data from the Ministry of Agriculture, Forestry and Fisheries for fiscal year 2021, 5.23 million tons of food waste is generated annually in Japan. Of this, 2.44 million tons is generated from households, and 2.79 million tons is generated from food manufacturing businesses, with business-related food waste accounting for 53% of the total.

(See data from the Ministry of Agriculture, Forestry and Fisheries)

Impact of waste on the social environment

Food waste during the food manufacturing stage is a major issue in aiming for a recycling-oriented society. In order to address this issue, it is important to be aware that discarded food not only has economic value, but also places a burden on the environment. Let's take a closer look at this.

Environmental impact

Food emits CO2 throughout the entire process, from production to consumption, and the amount of waste represents an amount of CO2 that is being wasted.

In order to reduce waste, which has a major impact on the social and environmental issues, various issues have been raised, including the establishment of legal frameworks and voluntary industry regulations.

Waste of energy resources

The food manufacturing process consumes a huge amount of energy resources such as water, electricity, and gas, and the disposal of waste means the waste of resources used in the production process. It has been pointed out that the waste of energy and water resources necessary for food production leads to environmental problems such as global warming and water shortages.

Economic loss

Food waste in the food manufacturing industry means wasted costs, time, and labor in production, distribution, and sales, resulting in economic losses. It also causes inequality in the supply of food to people suffering from hunger, and has the potential to develop into social issues such as global food insecurity.

As you can see, food waste in the food manufacturing industry has a serious impact on the social environment. Why does so much food waste occur? Here are some of the reasons why food waste increases.

Main causes of waste in food production

Problems on the production line

Problems can occur on the production line, that is, during the food manufacturing process. For example, it may be discovered later that there was a problem with the quality of the raw materials, or the quality of the food may deteriorate when production stops due to a breakdown in the manufacturing machinery.

Additionally, if the production line involves manual labor, food can become contaminated or contaminated, either of which results in large amounts of product having to be thrown away.

Problems with inventory storage and distribution

Food can be wasted if its quality deteriorates due to lack of proper temperature control during storage or transportation, or if food spoils due to inappropriate delivery methods.

The one-third rule in food distribution

The one-third rule is a business practice established in food distribution to ensure that products with relatively well-defined expiration dates are put on store shelves.

Although these rules are intended to ensure food safety for consumers, they have been reviewed in recent years because they lead to food and resource waste, and efforts are being made to improve them.

Excess production relative to demand

Farmers and fishermen sometimes produce and harvest more than is needed, which is often the case for foods that are vulnerable to natural conditions, market changes, weather, and other unpredictable factors.

In addition, food manufacturing often has difficulty predicting demand. This often results in excess inventory or shortages. Many companies hold excess inventory to avoid missing sales opportunities, which leads to an increase in food that is not sold in time for its expiration date and is then wasted.

As we can see from looking at some of the causes, waste loss is likely to increase as a result of actions taken to satisfy consumer needs. This is why it may be difficult to take steps to reduce waste loss when you are busy with your daily work.

However, this attitude can be changed by learning about the benefits that food manufacturers can receive by reducing waste.

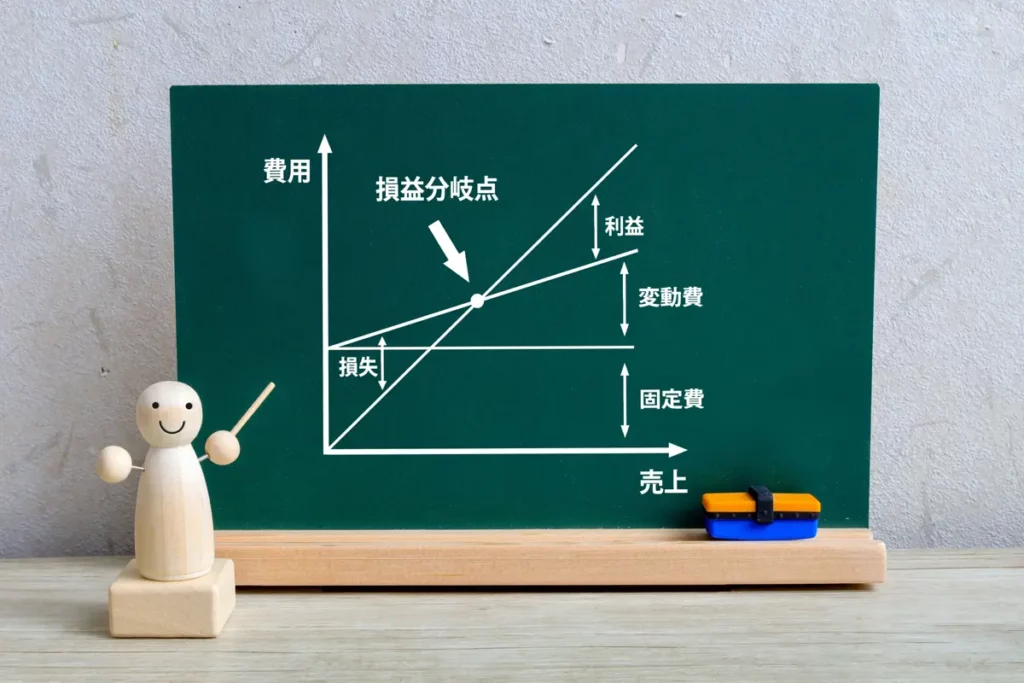

Benefits of reducing waste for food manufacturing companies

There are two main benefits to reducing waste. Both are important for companies, so you can see why they should work on reducing waste.

Reduce disposal costs and improve business profitability

When food is wasted, disposal costs are incurred. In addition, the costs spent on production are also wasted. The increase in disposal costs and production costs is a heavy burden for companies, and can put pressure on management.

Reducing waste makes it possible to reduce cost rates and product sales prices, which ultimately leads to improved customer satisfaction, operating profit margins, and management efficiency.

Improve your company's reputation and image

Reducing waste is recommended as an international goal for creating a better society as part of the SDGs. The importance and awareness of reducing environmental impact and contributing to sustainability is increasing, and it is now becoming an essential issue for food companies to improve their credibility and image.

As we have discussed so far, we have learned that the increase in food waste in the food manufacturing industry has a negative impact on the social environment and the company's economy, and that working to reduce food waste has important benefits for the company. Based on that, we will introduce some measures that companies can actually take to reduce food waste.

Measures to reduce waste in the food manufacturing industry

The food manufacturing industry is actively working to reduce waste. Let's take a look at some of the specific measures.

Production Line Automation

As mentioned earlier, one of the causes of waste is problems caused by manual labor on food production lines.

By automating manual tasks using machines, it is possible to prevent the risks that can occur with manual work, while at the same time improving production efficiency in terms of stable quality and work speed. It also leads to a reduction in waste by suppressing the occurrence of defective products and deterioration in quality.

Production schedule management

Production management to prevent excess production relative to demand is also important.

Nowadays, we live in an age where IT and AI can predict fluctuations in market demand. By utilizing cutting-edge technology to create production plans and adjust the amount of production, we can prevent waste caused by overproduction.

Thorough inventory management

Food manufacturing and sales companies often end up holding more inventory than they need in order to avoid lost opportunities due to stock-outs.

Excessive inventory leads to poor storage, which can cause quality deterioration, and if the expiration date passes during storage, the product cannot be sold and must be disposed of. In manufacturing, a lack of inventory can also cause production to stop, which can easily result in waste loss in the process.

Although it is a difficult problem, waste loss should be prevented through demand forecasting and appropriate inventory management and sales planning.

Adding high value to surplus food

Reusing products that are still edible but cannot be sold due to issues with their appearance or packaging, such as unsold, unused food or non-standard food, is also an effective way to reduce waste.

Non-standard fruits that still have a good taste can be made into a paste or cut into pieces to create other sales opportunities, and surplus food can be used as animal feed or fertilizer.

As mentioned above, we have introduced the causes of food waste and various measures to reduce it, but have you ever thought about the underlying reasons why food waste occurs?

It can be said that at the root of any of the problems that may be causing this is the existence of a "best before" date for food.

We will introduce noteworthy measures to resolve this fundamental issue and provide examples of companies that have achieved zero waste through these measures.

Measures to address expiration dates, which are the root cause of waste

Food loses flavor and quality over time, eventually becoming inedible.

Even if the food is still edible, it will be difficult to sell it if it is approaching its expiration date, which is set as a food safety standard, and if it has passed that date, it will not be able to be sold.

There are actually measures that can solve the problem of expiration dates, which is closely related to food waste.

Examples of using rapid freezing technology

If we could stop the passage of time, which affects food quality, or significantly extend expiration dates, perhaps we could one day achieve zero food waste.

The latest "rapid freezing technology" is attracting attention as a technology that can revolutionize the food industry. We will introduce a case study of a company that has used rapid freezing technology to solve not only waste but also many other issues, creating a virtuous cycle for its business.

What prompted us to introduce rapid freezer

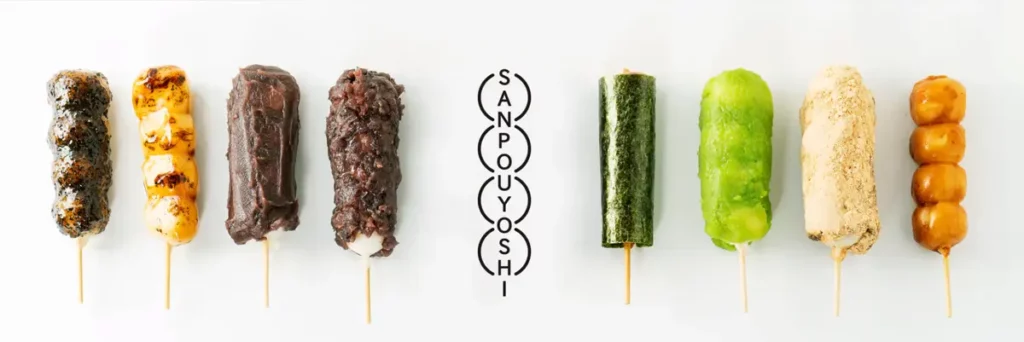

Active One Co., Ltd., a company that manufactures and sells Japanese sweets in Saitama Prefecture, prepares the sweets early every morning and operates a store for sale.

The main product, dango, is a sweet treat whose chewy texture is essential, but because it has a very short shelf life and hardens within a few hours of production, the company was concerned about the large amount of waste it would generate.

After thinking, "If we can extend the expiration date, we can provide the delicious taste of our dango to more people and reduce waste...", they decided to install the "Art Lock Freezer" rapid freezer that can freeze and preserve high-quality food.

Product development for frozen dumplings

Even if the machine is capable of freezing food to a high quality, it is not easy to reproduce the texture and flavor of the food after it has been thawed.

Through testing together with the product development team at Daybreak Co., Ltd., the manufacturer of the freezer that we used, we adjusted the recipe to suit a frozen product and created "frozen dumplings" that can reproduce the deliciousness of freshly made dumplings even after thawing after being stored in the freezer.

What the planned production system changed

Now that we can freeze the dumplings and store them for long periods of time, many of the issues that had previously existed in our production system have been resolved.

Increased sales due to expansion of trade area

The company expanded its business by selling frozen dumplings online, something that was not possible with dumplings, which have a short shelf life.

We were now able to deliver the delicious taste of dango to anywhere in Japan, and of course our sales increased.

Significant reduction in waste

We established a manufacturing and storage operation whereby any unsold dango in the stores is frozen and stored before it loses quality, and then shipped for mail order, eliminating most waste.

Improve productivity and eliminate opportunity loss

The system in which dumplings were produced early in the morning to be sold in stores during the day has changed to a planned production system in which dumplings produced during the day are stored in frozen stock and sold the next day or later.

As a result, they were able to increase production volume by 20%, from 1,500 to 2,000 bottles per day, without having to worry about waste, and by significantly improving production efficiency, they were able to eliminate lost sales opportunities.

The elimination of the burden of early morning work has enabled production work to be carried out during the day when more manpower is available, which has also led to a reduction in labor costs.

Eliminate labor shortage

Although Active One Co., Ltd. faces the issue of labor shortages, there has been no change in the number of staff before and after the introduction of the freezers.

However, with the same number of staff, work hours and production efficiency have improved, making it possible to use frozen inventory to handle busy periods and sudden large orders. Improved production efficiency also helps to alleviate labor shortages.

Profit margin increase by 3%

By not increasing the number of production staff and eliminating the need for early morning work, labor costs can be reduced. In addition, the reduction in waste also reduces the cost rate.

Furthermore, increased sales due to an expansion of the business area also boosted profits, resulting in an astonishing 3% increase in operating profit margin, despite the rising cost of raw materials for the dumplings.

As can be seen from this success story of a Japanese confectionery manufacturing industry, the introduction of rapid freezer and the use of flash freezing techniques not only eliminates the barrier of expiration dates and enables food to be preserved for long periods of time, but is also a measure that can solve various management issues and create a virtuous cycle.

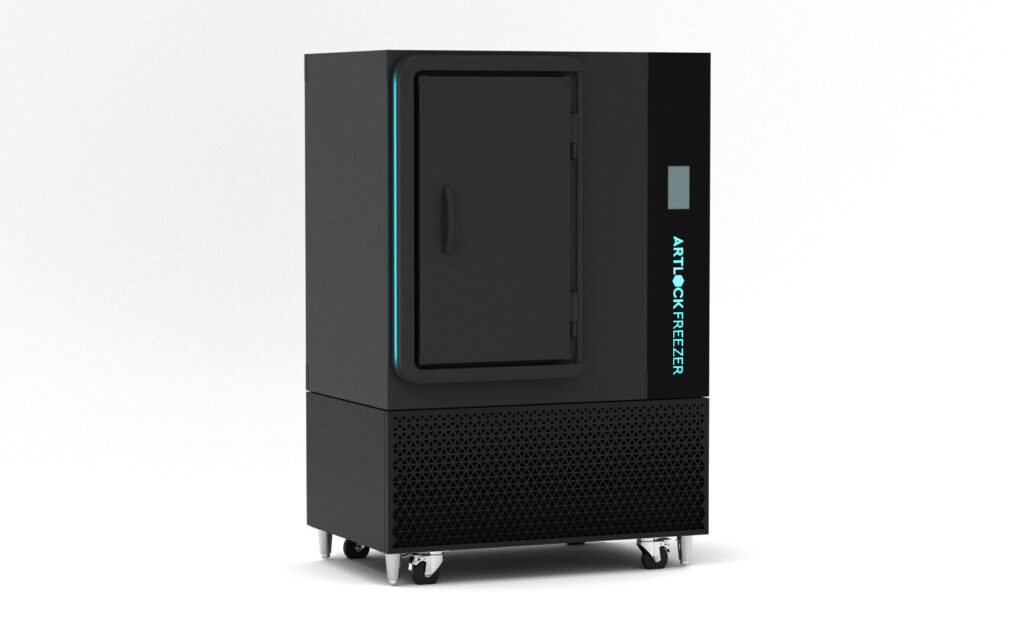

Features of Art Lock Freezer

There are many different types of rapid freezer, but flash freezer "Art Lock Freezer" introduced in this success story not only has the power to solve the company's problems, but also has the potential to improve business in the future.

We will introduce you to the benefits of installing Art Lock freezers, including their performance.

What is rapid freezing, which allows long-term storage without compromising quality?

rapid freezing is a freezing method that allows food to be stored for long periods without losing its quality. Quick freezing of food can prevent the destruction of food cells caused by the swelling of ice crystals that occurs during slow freezing. This allows the food to retain the same taste and texture after thawing as before it was frozen.

This method will allow an increase in the number of ingredients whose expiration dates can be significantly extended, making it also effective in reducing food waste.

Benefits of rapid freezing

- Best before date extension

- Preserves the freshness, flavor, and texture of food, even after thawing

- No additives such as colorings or preservatives are required and it can be stored for a long time.

What will become possible for the food manufacturing industry if a system that is less affected by expiration dates can be created by utilizing rapid freezing technology? I will explain this in detail, dividing it into two main points.

Establishment of a planned production system

Being free from expiration dates has great significance for the food manufacturing industry. Not only will it make it easier to control purchased inventory and production volume, but it will also enable mass production and storage of products when labor is readily available, regardless of demand, making planned production and sales possible.

In addition, because it allows for a stable procurement and supply of food that is not dependent on the season or harvest time, or on fluctuations in cost, it is expected to significantly reduce cost rates and food waste, which in turn leads to improved operating profit margins.

Improving working conditions

In the food manufacturing industry, working hours and production volumes are often restricted by expiration dates, but rapid freezing technology can achieve more than just planned production and reduced food waste.

By making it possible to plan production, manufacturing operations that previously took place in the early morning and late night hours can be carried out during the day and frozen storage can be performed, and by utilizing frozen inventory, operational efficiency can be improved to allow for the implementation of fewer manufacturing operations.

In addition, there are cases where companies that operate multiple stores have consolidated their manufacturing operations at CK and transported frozen ingredients to each store, thereby achieving significant improvements in productivity and lowering cost rates.

At the same time, it also leads to a reduction in working hours and labor and manufacturing costs, reducing the burden on employees and ensuring they have more time off.

Furthermore, improved employment conditions will expand the possibility of recruiting talent and alleviate labor shortages, creating a virtuous cycle in the working environment.

Reasons to choose ART ROCK FREEZER

We recommend the batch-type rapid freezer "Art Lock Freezer" for food manufacturing companies, depending on the ingredients to be frozen and the production volume.

We will explain two particularly important points about what makes rapid freezer highly compatible with the food manufacturing industry.

rapid freezing is possible while preventing food from drying out

Micro Window System

Art Lock Freezers are equipped with a function that creates a special cold wind. This allows the fine, gentle cold air to hit food from multiple directions, freezing it evenly while preventing the food from drying out.

Most conventional rapid freezer apply strong cold air to food from one direction, which can cause food to dry out or freeze unevenly during the freezing process, resulting in a deterioration in quality.

In terms of freezing quality, the Art Lock Freezer's technology of "freezing food quickly without drying it out" differentiates it from other freezers in that it can freeze and preserve food while maintaining its high quality, and it can be said that there are many benefits to introducing it to the food manufacturing industry.

Equipped with functions to ensure uninterrupted production

Anti-frost mechanism

Art Lock freezers are designed to prevent frost from forming inside the freezer. Conventional rapid freezer require defrosting, which means production operations have to be stopped every few hours. However, Art Lock freezers do not require defrosting, meaning food can be produced without stopping operations.

Additionally, our machines are differentiated not only by the ease of cleaning and maintenance of the interior, but also by how easy they are to operate.

Smart Freeze Feature

Art Lock freezers are equipped with sensors inside, allowing them to automatically select the optimum operation mode for the quality and quantity of food placed inside the freezer and perform the freezing process.

In addition, AI will alert you to any abnormalities within the warehouse (such as over capacity or abnormal operation), helping to prevent freezing failures and mechanical breakdowns.

The fact that it can be operated without any errors and without any special skills or knowledge means that it is highly efficient when used by part-time or casual staff.

As mentioned above, Art Lock freezers have an extremely high production efficiency within a given period of time because they "do not stop production," "prevent failures and breakdowns," and "anyone can operate them." They are chosen by many companies because they can contribute to improving business operations, such as reducing working hours in food manufacturing.

Conclusion

Food waste in food production has various impacts on the economy and the environment. Through understanding the causes and taking effective measures, it is possible to reduce waste.

This time, we focused on the existence of "best before dates," which is the fundamental reason for food waste, and introduced an example of using a "rapid freezer" as a method to address this issue.

Utilizing the freezing technology of rapid freezer not only enables long-term storage of food and planned production, but also increases production efficiency by improving business operations and working environments, leading to increased profit margins.

If you are interested in introducing rapid freezer as a measure to address the management issues facing your food manufacturing business, please feel free to contact us and we will provide you with a more detailed explanation of the Art Lock Freezer product and individual consultations.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Fisheries/Fisheries Cooperative] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_suisan_img_01.jpg)

![[Recommended for lunch boxes too! ] Introducing recipes and methods for freezing pasta!](https://shunkashutou.com/wp-content/uploads/2023/10/93f66b71b92cbe1085d41c4ed80d7726.jpg)

![[Explanation with photos! ] Introducing the method and recipe for freezing komatsuna](https://shunkashutou.com/wp-content/uploads/2023/09/5d2a19a6e6cfb5ad0329d8fce162f292.jpg)

![[Can it be frozen? ] How to freeze milk, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/d0390cbc7a5e9a76c11d5b9eff3b4a5b.jpg)

![[Explanation of how to fry! ] How to freeze and thaw pork cutlet, remake recipe!](https://shunkashutou.com/wp-content/uploads/2023/10/0a4143ad8ea0cc6bb6fdab8c74fab407.jpg)

![[Rapid freezers in 2021] Market Trends and Customer Success Stories](https://shunkashutou.com/wp-content/uploads/2020/12/7F9A9CB9-A494-4E6A-946E-079279C596E6.jpeg)

![Explaining how to freeze Maitake mushrooms, their nutritional value, and recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/9face03809f7fcaf2e3599773b2e8c80.jpg)

![[Explanation with photos! ] How to freeze taro, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/116858380_-768x512-1.jpg)

![Introducing how to freeze/thaw salmon roe and how long to store it [includes carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/09/236b884b68d07d2f5983f2b9ea66583d.jpg)

![[Introducing tricks and time-saving techniques! ] How to freeze ginger-yaki, carefully selected recipes](https://shunkashutou.com/wp-content/uploads/2023/10/ef145c31655c5774469e05b5e892207b.jpg)

![[Can it be frozen? ] How to freeze and thaw okonomiyaki, arrangement recipe!](https://shunkashutou.com/wp-content/uploads/2024/01/58bc763c02f23a2a6442d6449853a67b.jpg)

![[Can it be frozen? ] Introducing recipes and methods for freezing avocados!](https://shunkashutou.com/wp-content/uploads/2023/07/7b25b2d45ff983fca2a15b6ad7edf369-1.jpg)

![[Introducing case studies as well!] 5 reasons why curry restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/07/2a0deb9a6db53165f0a4938bc80cee46.webp)

![Introducing recipes and methods for freezing and thawing bananas [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/07/494e7567627fb35e47ee5cb0e06e142c.jpg)

![How to freeze rice cake, expiry date, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/bd019f04ad570f697ffefe9ffd2e1e71.jpg)

![[Explanation with photos! ] How to freeze beef, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/8717f2a867f52157bab47841b0f29019.jpg)

![[Explanation with photos! ] Shiitake mushroom freezing method and storage period, 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/shiitake-768x512-1.jpg)

![[Explanation with photos] How to freeze nagaimo, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/c46c238f2048d76de403dfd81ddad1f3.jpg)

![[Explanation with photos! ] How to freeze green beans, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/09/f3dbbe5b1d05a50f514a833efdceced9.jpg)

![Introducing recipes and methods for freezing spinach [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/spinachh-768x512-1.jpg)

![[Fruit becomes dessert! ] How to freeze kiwi and sweets recipes](https://shunkashutou.com/wp-content/uploads/2023/09/ecc0fc2bc14391ea13ce2e7a43d1416e.jpg)

![[Can it be frozen?] Stew freezing method, storage period, and arrangement recipe](https://shunkashutou.com/wp-content/uploads/2023/10/f599b814ea21eef57604e4ceb2518d5b-1.jpg)

![[Convenient for lunch boxes! ] How to freeze fried noodles and 5 different recipes](https://shunkashutou.com/wp-content/uploads/2023/10/yakisoba-768x512-1.jpg)

![[Can it be frozen? ] How to freeze dried daikon radish and arrange recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/84f89f802d6869949972432e7b3be19c.jpg)

![[Explanation with photos] How to freeze salmon fillets, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/fb96564ba06a8cc88a72f0c971ad54e5.jpg)

![[Explanation with photos! ] How to freeze mackerel fillets and 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/bf45f102162a8d43387d3a8d3e538034.jpg)

![Introducing how to freeze carrots and recipes [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/837a12b0247130309b466717f2b8c53c.jpg)

![[Achieving instant freezing at home] The evolving freezing function of home refrigerators](https://shunkashutou.com/wp-content/uploads/2015/10/93e403bcf18bda6b2d63c7c74fdef064.jpg)

![[How long does frozen fish and meat last? ] Interesting expiration dates and tips to extend the shelf life](https://shunkashutou.com/wp-content/uploads/2023/08/f124221382987fe32d0ffda6b6f497c1.jpg)

![How to freeze bitter gourd and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/8fe0cb793c93d4fd4c26f352d17e5b87.jpg)

![[Dramatically extends the shelf life of vegetables! ] What is blanching process?](https://shunkashutou.com/wp-content/uploads/2023/07/8fce721a563a0e86a740b4d11dc63766.jpg)

![How to freeze celery, nutrition, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/serori-768x512-1.jpg)