What is the manufacturing process that maintains the safety of frozen foods? Explaining standards and actual procedures

The frozen food market is rapidly expanding due to the coronavirus pandemic. In addition, in recent years, it has become possible to enjoy the taste of Michelin-rated restaurants created by top chefs at home through frozen foods.

With the number of delicious frozen foods on the rise, some people may be thinking about selling their own dishes and foods frozen. In some cases, when freezing your own food products, you may be concerned about the loss of taste or quality.

In this article, we will first introduce the manufacturing process of frozen foods and the standards for frozen foods from the perspective of the manufacturing process. Then, in the second half, we will introduce the "rapid freezing" technology that is essential to the frozen food manufacturing process and the recommended rapid freezer "Artlock Freezer."

目次

Introducing the manufacturing process of frozen foods

First of all, there are three main definitions and standards for frozen foods:

- Standards for ingredient standards under the Food Sanitation Act

- Standards in the quality labeling standards of the Food Labeling Act

- Standards established by the Japan Frozen Foods Association

Many commercially available frozen foods comply with the following standards indicated in ③.

- Pre-treatment (removal of inedible parts, cooking, etc.)

- Be frozen quickly so that it quickly passes through the maximum ice crystal formation temperature range (approximately within 30 minutes)

- It must be placed in a container/package and have the specified labeling.

- Always stored at -18 degrees Celsius or below throughout every stage from manufacturing to sales.

In this chapter, we will take a closer look at the manufacturing process of frozen foods while comparing them with the above standards.

1.Food pretreatment/cooking

This process falls under the first of the four conditions for frozen foods: ``Pretreatment (removal of inedible parts, cooking, etc.) has been performed.''

When producing frozen foods, the ingredients are first pretreated. Preprocessing is a general term for the following operations that remove inedible parts from foodstuffs.

- Vegetables: wash and cut

- Fish: Peel off the scales, remove the internal organs and head, and cut into three pieces, etc.

By performing this pretreatment, there is no need to discard unnecessary parts in home kitchens or restaurant kitchens, and frozen foods can be used directly for cooking.

2. rapid freezing of food

This process applies to the second of the four conditions for frozen foods: ``The food must be rapidly frozen so that it quickly passes through the maximum ice crystal formation temperature range (approximately within 30 minutes).''

Ingredients and foods sold as frozen foods are frozen using a method called" rapid freezing "to maintain their quality. The characteristics of rapid freezing can be easily visualized by comparing it with so-called general freezing.

General freezing is like placing food outdoors in the extremely cold temperatures of Hokkaido, for example, and slowly freezing it at negative outside temperatures. On the other hand, rapid freezing is a freezing method that meets standards such as ``the food passes through the maximum ice crystal formation temperature range of -1 to -5 degrees Celsius within 30 minutes.'' .

Ice crystals will be kept small if the maximum ice crystal formation zone is passed within 30 minutes. As a result, there is less damage to food, which is a major advantage of rapid freezing.

3. Packaging frozen foods

This is a process that applies to the third of the four conditions for frozen foods: ``The food must be placed in a container or package and the specified labeling must be displayed.''

In order to maintain the quality of rapid freezing foods, it is necessary to take measures to prevent deterioration during the storage and distribution processes after production. Therefore, it is important not only to simply wrap and seal the food, but also to choose a packaging material that is suitable for the food and ingredients.

In addition, after frozen foods are packaged, they must be labeled with information such as product specifications, cooking methods, and ingredients. The combination of appropriate packaging that maintains food hygiene and information labeling is called "consumer packaging (commercial packaging)."

4. Store and distribute under temperature control

This process applies to the last of the four conditions for frozen foods: ``Through every stage from manufacturing to sales, the food must be stored at -18 degrees Celsius or below.''

After production of frozen foods, thorough temperature control is required in order to store and distribute them at -18 degrees Celsius or below. This -18 degrees is an international voluntary standard.

In contrast, Japan's Food Sanitation Law stipulates that the storage temperature for frozen foods is -15 degrees Celsius or lower. This -15 degrees was set because if the temperature dropped any further, microorganisms on Earth would no longer proliferate. In other words, if the temperature is below -15 degrees, frozen foods are less likely to spoil.

However, at -15 degrees, the taste and quality of frozen foods may change. For this reason, the frozen food industry has set a voluntary standard of -18 degrees Celsius or below based on the results of a U.S. survey.

Frozen food standards from the manufacturing process perspective

Frozen foods have standards for each manufacturing process. In this chapter, we will introduce the four standards and manufacturing process characteristics of frozen foods.

Frozen food consumed after heating

Frozen food that is eaten after being heated. This applies to foods that are heated in a microwave or hot water bath. It can be divided into two types depending on whether it was heated before freezing.

- Heating just before freezing: Food heated just before freezing

- Unheated just before freezing: Food that has not been heated just before freezing

In addition, at quarantine stations under the jurisdiction of the Ministry of Health, Labor and Welfare, frozen foods that are consumed after heating are classified as ``frozen foods that have been manufactured or processed and are not frozen foods that are consumed without heating.'' It is explained as follows.

Whether the food is heated just before freezing or unheated just before freezing depends on the product, but in general, fried foods such as french fries, croquettes, and fried shrimp fall under the category of frozen foods that are consumed after heating.

Reference: Standards for each food (frozen foods) (Osaka Quarantine Station Food Inspection Division)

Unheated frozen food

Frozen food that can be eaten as is without being heated before eating. Specifically, this would include cakes and fruits.

In addition, the definition of frozen food that is consumed without heating does not ask whether the food was heated before thawing. In the end, the types are classified based on whether or not they should be heated before eating.

Frozen seafood for raw consumption

Frozen shelled or filleted fresh seafood that can be eaten raw. Because it is meant to be eaten raw, it is not heated during production, and although it does require thawing when eaten, it does not require heating. For frozen fresh seafood for raw consumption, only those in packaging containers fall under this category.

Typical examples include frozen foods such as sashimi and sushi toppings.

Frozen fresh seafood, filleted or shelled

Frozen shelled or filleted fresh seafood. The difference from the above-mentioned frozen fresh seafood for raw consumption is that it is not intended for raw consumption.

This type falls under the category of frozen foods that are consumed after heating. Therefore, it must be cooked before eating, but it is not heated at the time of manufacture. Specifically, this would apply to seafood that is put in a hot pot.

What rapid freezing, which is essential to the frozen food manufacturing process?

In order to produce frozen foods, the" rapid freezing "equipment that I mentioned earlier is essential. In this chapter, we will explain in detail what rapid freezing is, citing specific benefits.

Why rapid freezing is necessary for frozen foods

For example, when manufacturing and selling specialty dishes and ingredients as frozen foods, it is extremely important not to compromise the taste or quality of the food.

For example, when food and ingredients are slowly frozen using a home freezer, it takes many hours to pass through the maximum ice crystal formation temperature range where ice crystals tend to become coarse, making up 70 to 80% of the food. As water turns into ice, its volume expands, destroying the cells of the food.

Also, if you freeze the food slowly, the umami ingredients and water may leak out from the broken cells, resulting in a loss of flavor and texture.

On the other hand, rapid freezing is a technology that allows food to pass through the maximum ice crystal formation temperature range, where the water in the food turns into ice crystals, within 30 minutes. rapid freezing suppresses the growth of ice crystals, making it difficult for the cellular structure of the food to break down.

As introduced in the four conditions above, the Japan Frozen Foods Association (General Incorporated Association) recommends that companies have a process that allows for rapid freezing in order to manufacture and sell frozen foods of higher quality. I'm looking for it.

Can preserve the original taste and flavor

When food passes through the maximum ice crystal formation temperature range within 30 minutes through rapid freezing, the cells of the food are less likely to break down, making it difficult for the following elements of dishes and ingredients to deteriorate.

- freshness

- Taste

- quality

- Color

- flavor

- texture etc.

When we think of "frozen foods," we tend to think of them as being for home use, but rapid freezing technology is also widely used for commercial purposes, as it makes it easier to maintain the appeal of the foods mentioned above.

Can freeze large amounts of food

By introducing rapid freezing technology, you can compress the time it takes for dishes and ingredients to completely freeze. For example, the results of a survey by the Japan Frozen Foods Association show that there is a difference of more than three times in the time it takes for food to reach -20 degrees Celsius between ordinary freezing methods (slow freezing) and rapid freezing. Masu.

However, the specific time required will of course vary depending on the type of food and the type of freezer used. This cannot be said in general.

However, if rapid freezing system is introduced, the amount of frozen food that can be produced per day can be significantly increased by shortening the freezing time.

Source: Why rapid freezing is good (Japan Frozen Food Association)

Safe in terms of hygiene

It is said that the growth of many bacteria is delayed at temperatures below 10 degrees Celsius, which is the standard temperature inside the refrigerator, and stops at temperatures below -15 degrees Celsius.

If you use rapid freezing technology to freeze dishes and ingredients all at once, you will be able to quickly pass through the temperature range where bacteria stop growing. As a result, food poisoning problems are less likely to occur.

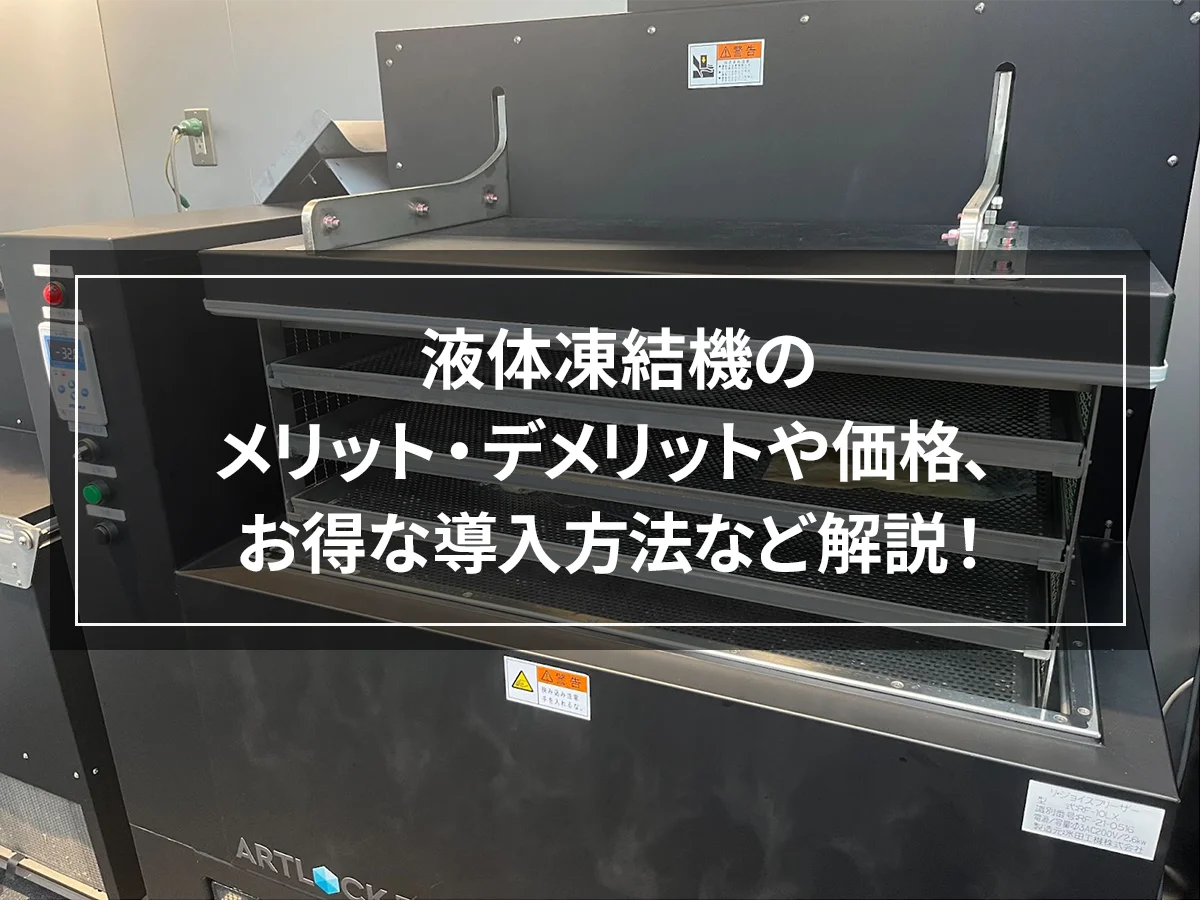

Artlock Freezer is recommended for manufacturing frozen foods.

Daybreak's "Artlock Freezer" is recommended for those who produce high-quality frozen foods.

The feature of Artlock Freezer is that it can rapid freezing food by surrounding it with gentle cold air. Unlike general rapid freezer, this system does not apply strong cold air to the food from one direction, so it minimizes damage to the food and prevents drying, discoloration, and oxidation.

In addition, foods frozen in the Artlock Freezer can be stored for long periods of time, such as six months. Therefore, it is a system suitable for manufacturing frozen foods, as it allows you to store large quantities of food for a long time before shipping.

Conclusion

The manufacturing process for frozen foods is designed based on strict conditions as introduced in the article. Therefore, the general process for manufacturing frozen foods remains basically the same at all factories.

Manufacturers of frozen foods need to manage the entire process, from pre-treatment before freezing to packaging after freezing. Among these, rapid freezing, which has been attracting attention in recent years, can be thought of as a mechanism that is at the core of the frozen food process.

Daybreak, which develops and sells Artlock freezers, provides total consulting related to rapid freezing. If you are interested, please contact us from the page below.

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![Introducing the method and recipe for freezing green onions [Explanation with photos]](https://shunkashutou.com/wp-content/uploads/2023/09/negi5-768x512-1.jpg)

![[Can it be frozen? ] 5 recipes for yogurt freezing and shelf life!](https://shunkashutou.com/wp-content/uploads/2023/10/yogurt-catch-768x512-1.jpg)

![Introducing how to freeze/thaw salmon roe and how long to store it [includes carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/09/236b884b68d07d2f5983f2b9ea66583d.jpg)

![[Osechi remake dishes too! ] Introducing the method and recipe for freezing black beans](https://shunkashutou.com/wp-content/uploads/2023/09/9bcd5b0667eef32b7c7daf786e01172f.jpg)

![[Save onions in the freezer! ] Introducing storage methods and recipes with photos](https://shunkashutou.com/wp-content/uploads/2023/10/9d2c1259f1c42d7a0e3b61af361e5da8.jpg)

![[Dramatically extends the shelf life of vegetables! ] What is blanching process?](https://shunkashutou.com/wp-content/uploads/2023/07/8fce721a563a0e86a740b4d11dc63766.jpg)

![[Explaining how to freeze fish! ] Introducing storage period and thawing method!](https://shunkashutou.com/wp-content/uploads/2023/08/a794d4ac4e5f56cd881ba06a0edf9449.jpg)

![[Mass production and space saving] What is the secret of the spiral freezer structure?](https://shunkashutou.com/wp-content/uploads/2024/08/f564637ad1713707bc4672347d147d5e.webp)

![[Can it be frozen? ] How to freeze cabbage rolls, storage period, and recipe](https://shunkashutou.com/wp-content/uploads/2023/10/f5c1db9a17ef7843ffd45f5ccb160ed5.jpg)

![Introducing how to freeze burdock and recipes [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/0812c28da547fe267723143edad2bfed.jpg)

![[With photos] Lemon freezing and storage period, recipes for how to use frozen lemons](https://shunkashutou.com/wp-content/uploads/2023/09/21a01b705aff194717e200bf6dc6ce5b.jpg)

![[Make frozen oysters even more delicious! ] Correct thawing method and usage recipes](https://shunkashutou.com/wp-content/uploads/2023/10/5855c6e6d6dbdb298f86405b4b522329.jpg)

![How to freeze sweet potatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/36256af24531b73a036523ba73bdf9ec.jpg)

![Thorough explanation of how to freeze eggplant and its storage period! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/03fe8d79948a39047616383e2d3fb64a.jpg)

![Introducing the method and recipe for freezing eringi mushrooms [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/a360f0e10b69512c896510215ae51a7f.jpg)

![[Achieving low cost and high quality] The problems of pubs can be solved with a quick freezer!](https://shunkashutou.com/wp-content/uploads/2024/09/11d55612344a4cbad2ad506ae700c81b.webp)

![[Which products are popular? ! ] Recommended frozen food ranking](https://shunkashutou.com/wp-content/uploads/2023/08/frozen-food-ranking-1024x682-1.jpg)

![[Thorough guide to preserving meat] Preservation methods, expiration dates, thawing methods, rapid freezing](https://shunkashutou.com/wp-content/uploads/2023/09/ec61889773cfed9c75aa97d9ca6c96dd-1.jpg)

![How to freeze tomatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/tomato-768x513-1.jpg)

![[Explanation with photos! ] How to freeze pumpkin, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/10/36d3edf3acec7cf27351bd1211e770ac.jpg)

![[Can it be frozen? ] How to freeze mashed potatoes, how long they can be stored, and how to use them](https://shunkashutou.com/wp-content/uploads/2023/09/b7f3f25102051473b7c2f9452840a6f4.jpg)

![[Explanation with photos! ] How to freeze butter, storage period, and 5 recipes](https://shunkashutou.com/wp-content/uploads/2023/08/4e4d4fde2efeae3d997d4356f1cc75c1.jpg)

![[Can it be frozen? ] How to freeze bacon, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/07/52dff5bc109cd400879fbf9bb35b3856.jpg)

![How to freeze celery, nutrition, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/09/serori-768x512-1.jpg)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2024/09/661ea3ee6264fab6520017622c656870.webp)

![How to freeze apples and what is their nutritional value? Perfect for baby food! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/cf0380a4b371d2f43e0f0ed99c7344a2.jpg)

![How to freeze rice cake, expiry date, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/bd019f04ad570f697ffefe9ffd2e1e71.jpg)

![[Can it be frozen? ] Introducing how to freeze ham and delicious recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/867d7b924bf17d95bedba60a6503e00e.jpg)

![[Distribute high quality mangoes! ] New frozen processing of mangoes using rapid freezing!](https://shunkashutou.com/wp-content/uploads/2024/08/4e9ff0df5721aa6f8fbdfae6d56ad787.webp)

![[Commercial use] Thoroughly investigate the cause of frost forming in the freezer! How to prevent frost formation?](https://shunkashutou.com/wp-content/uploads/2024/08/09c17e4deeb1ac0cdc5a513eaf89ab1a.webp)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![[Must-see for bakers] 6 reasons why bakeries should use rapid freezing](https://shunkashutou.com/wp-content/uploads/2021/02/f92a102c9d3cc8c63dc7e509ce6d35d2.jpg)

![[Achieving instant freezing at home] The evolving freezing function of home refrigerators](https://shunkashutou.com/wp-content/uploads/2015/10/93e403bcf18bda6b2d63c7c74fdef064.jpg)

![[Instant cooling at -196℃] What's up with cooling equipment that uses liquid nitrogen?](https://shunkashutou.com/wp-content/uploads/2024/10/4b219d54bd662f10cbae6ea211f612dd.webp)

![Types of rapid freezer and purchasing points! [Examples of failures in machine selection! ? ]](https://shunkashutou.com/wp-content/uploads/2015/04/e68b2ac878e110c2a4639a33271057d1_s-1.jpg)

![[Solving freezing problems] Performance and price of Re-Joice Freezer](https://shunkashutou.com/wp-content/uploads/2024/10/6bf8562954d67708f4b7808011fa9245.webp)

![[Used in various fields] Points to note when purchasing liquid nitrogen](https://shunkashutou.com/wp-content/uploads/2024/08/864ed88d3bcf695fd1a9af88d772606c.webp)