[Must-see for bakers] 6 reasons why bakeries should use rapid freezing

“We always want to provide freshly baked bread!”

"Unsold bread becomes waste..."

“I want to sell my special breads through mail order!”

There may be many people who have such problems.

By introducing rapid freezing,

・計画生産が可能➡廃棄ロス削減、機会損失がなくなる

・長期保存が可能➡オンライン販売を可能にし、販路を拡大

It is possible to turn various challenges into profits.

On this page, we will introduce "rapid freezing" in detail, which solves all of these problems.

In particular, the 6 benefits of using rapid freezing are a must-read for bakery businesses facing challenges!

目次

- 1 bread?What is the reason for the short shelf life of

- 2 Frozen bread market is hot in recent years

- 3 Why is “rapid freezing” effective for long-term storage of bread?

- 46 benefits of using rapid freezing

- 5Is only baking possible for rapid freezing? What about dough and semi-baked bread?

- 6 Introduction example of rapid freezing of bread

- 7 Conclusion

What is the reason for the short shelf life of bread?

Do you think that bread cannot be stored for a long time?

It is true that bread deteriorates quickly and will not last long if stored at room temperature. What factors are behind this?

One is "drying".

Bread begins to dry after it is baked. This is because the moisture contained inside the bread evaporates into the air, which leads to the "hardness" of the bread.

The second factor is starch aging.

In general, starch begins to undergo ``aging'' (beta conversion) when the temperature drops. Starch aging is a phenomenon that occurs when starch that has been gelatinized (gelatinized) attempts to return to its original state.

This causes the water contained in the starch to be lost.

*Gelinization (gelatinization): Starch becomes pasty.

Starch is particularly susceptible to aging between 0°C and 5°C, so storing it in the refrigerator is not recommended. On the other hand, if the temperature is above 60℃ or below 0℃, starch will stop aging.

Considering the risk of spoilage (growth of microorganisms), etc., storage at temperatures below 0°C is considered an appropriate method.

Furthermore, there are two types of starch components: amylose and amylopectin.

If the proportion of ``amylose'' in starch is high, it tends to deteriorate easily, and if the proportion of ``amylopectin'' in starch is high, it tends to be difficult to deteriorate. In recent years, the proportion of amylose contained in wheat has been reduced, and wheat has been developed that contains starch with a simple amylopectin structure.

This has made it possible to produce bread that does not become hard even after about three days. However, this only delays hardening, and over time it will become harder.

Based on the above, bread cannot be stored for a long time because its quality deteriorates when stored at room temperature or refrigerated.

As a countermeasure, there is a method called `` freezing preservation.''

but…

"Frozen x Bread"

What impression do you have?

"It becomes hard" "It has a crumbly texture"

Many people have this negative impression.

Frozen bread market is hot in recent years

Surprisingly, frozen bread has been gaining popularity in recent years. The idea that freezing bread deteriorates in quality and makes it unsalable as a product has been overturned.

Frozen bakery products began to appear on the world market around 1953, and now in Japan, frozen bakery products are popular in hotels, bridal shops, large companies, small and medium-sized businesses, and by 2023, the frozen bread market will be It is predicted that the market will be worth approximately 200 billion yen.

Shikishima Bakery, famous for Pasco, has a brand called ``Frozen Bread After Baking,'' and a company specializing in frozen bread has also been established and has achieved success.

A company called ``STYLE BREAD'' in Gunma Prefecture is expanding its sales channels year by year to sell ` rapid freezing bread.''

The company sells frozen bread to more than 3,000 hotels and restaurants, and has recently launched a brand for consumers. It has a good reputation, and we can see that demand for frozen bread is increasing.

View materials on rapid freezing bread

Why is "rapid freezing" effective for long-term storage of bread?

What methods are effective for long-term storage of bread?

The answer is "rapid freezing."

So why does it have to be "quick" frozen?

There are two types of freezing methods: slow freezing (normal freezing method) and rapid freezing. We will introduce the differences between them.

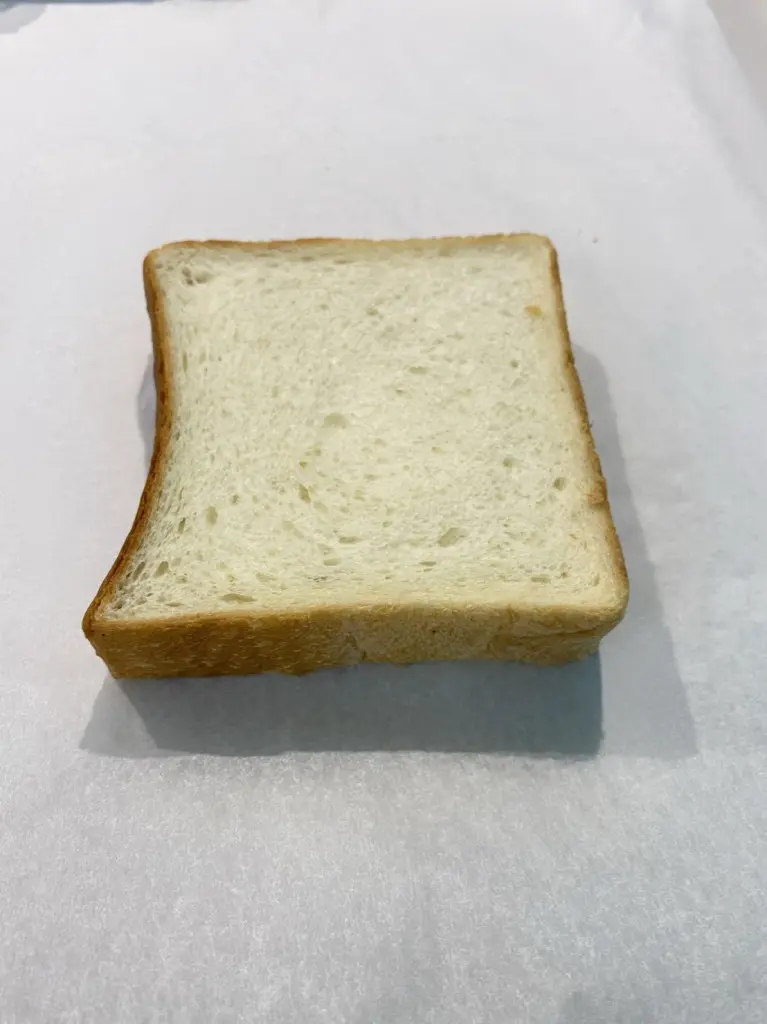

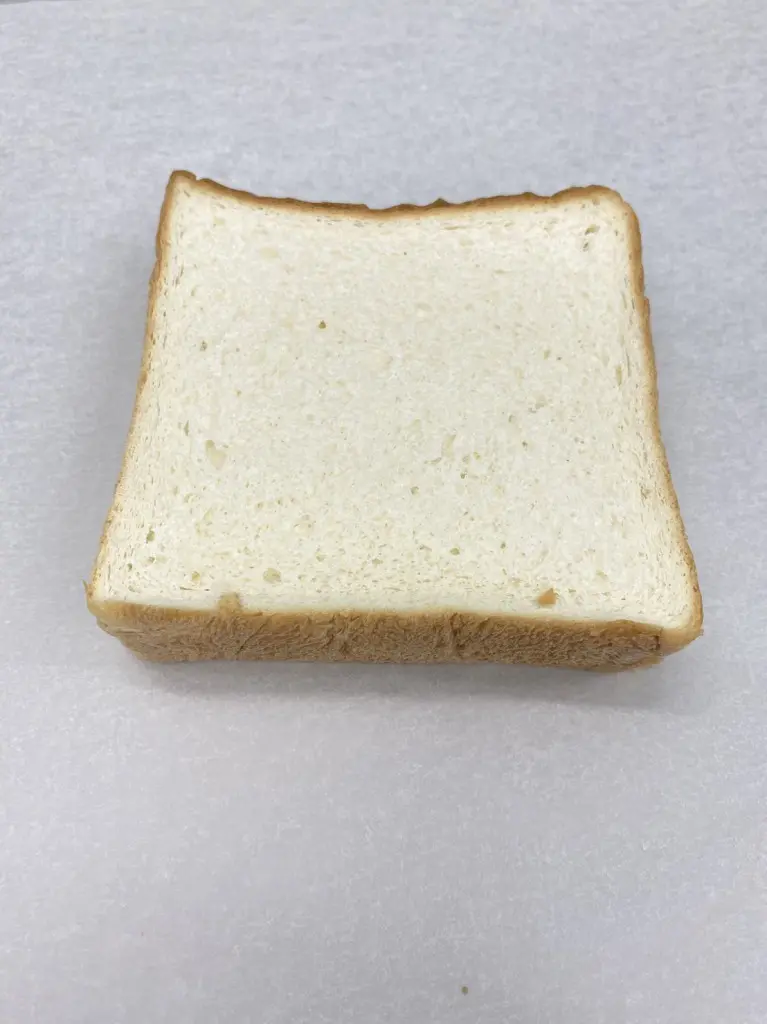

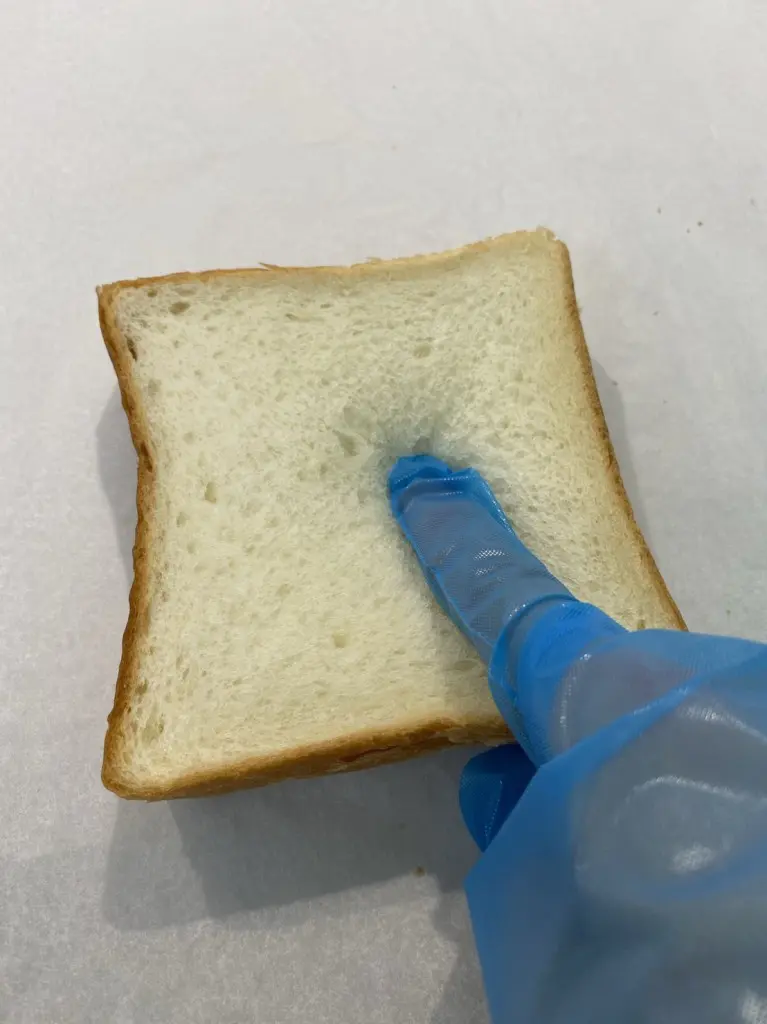

This is a photo of bread that was rapid freezing.

① Before rapid freezing

②After rapid freezing

③After thawing

As you can see from the appearance, no significant changes were observed between before and after rapid freezing. The softness and moist texture of the bread are also maintained.

Why does rapid freezing preserve quality?

As mentioned earlier, starch begins to dry from the moment the bread is baked, so the key to determining quality is how quickly the moisture contained in the bread can be frozen.

By freezing freshly baked food, you can enjoy the freshly baked taste after thawing without losing quality.

During the freezing process of food, the temperature range where ice crystals that impair quality are likely to form is called the "maximum ice crystal formation temperature range", but if slow freezing (normal freezing method) passes through this range slowly, the internal structure of the food will deteriorate. This may cause damage to the food.

From this point of view, you can understand that rapid freezing is effective for long-term storage of bread.

When comparing slow-frozen bread and rapid freezing rapid freezing bread has a stronger flavor and is softer.

Some people may say, ``I can't tell if the quality really changes...'' just by looking at the photos.

At our company, customers can actually try out the ingredients they handle in multiple rapid freezer.

Many of our customers come from far away, and we have many visitors every day, so if you are interested, please feel free to contact us. (If you are unable to come to the test room due to distance, etc., we also offer mail-in tests.)

6 benefits of using rapid freezing

rapid freezing enables the long-term preservation of high-quality bread, which solves many of the problems faced by manufacturing and sales industries with the following benefits:

①Reducing waste loss

Loss is often a problem in the bread manufacturing and sales process.

Generally speaking, in the bread industry, more bread is often produced than is demanded, and the current situation is that unsold items are often discarded. It is said that the loss rate is as high as 3-5%.

On the other hand, since bread is not a food that can be prepared immediately, there remains the issue of "opportunity loss" in that it cannot be provided at the timing that the purchaser wants.

By introducing rapid freezing,

・供給量を細かく調整できる➡需要にマッチした生産が可能

・余分にパンを生産することがなくなる➡食品ロス削減+利益アップ

There is a big advantage.

② Supply and demand adjustment

Many industries have been hit hard by the recent coronavirus pandemic. And the bread industry is no exception.

"We couldn't sell the bread we had prepared, so we ended up with a lot of leftover bread."

These problems can occur not only due to the coronavirus pandemic but also due to various factors such as weather and disasters.

Because bread cannot be made in advance, it has been difficult to adjust supply and demand.

By introducing rapid freezing, it becomes possible to sell the quantity you want when you want to sell, and to provide the quantity commensurate with demand when demand is low.

③Improvement of working environment/measures against labor shortage

In private bakeries, the products may be produced by one person or a small number of people.

On the other hand, there is not only one type of bread.

Providing a diverse product lineup in time for store opening hours requires a considerable amount of work time.

Also, it takes longer to make bread compared to other foods. Making bread dough requires fermentation, and each step takes time and effort, such as baking the dough in an oven.

In such an environment, it becomes necessary to work outside of regular business hours, such as preparing bread early in the morning or late at night, and in fact, I often hear stories of workers working on holidays to prepare bread to be shipped the next day. If this kind of work environment continues, physical and mental fatigue will accumulate.

However, this problem can be solved at once by introducing rapid freezing. Simply put, it makes it possible to "improve business efficiency."

Introducing rapid freezing allows you to make food ahead of time, reducing labor and time required for business operations.

If you prepare ahead of time, you won't have to prepare until late at night.

If you prepare large quantities when you have time and rapid freezing, you can also reduce labor costs.

④ Expand sales channels

Bread cannot be stored for long periods of time, so is it difficult to sell it in faraway places? Don't you think so?

There is no such thing!

rapid freezing allows products to be sold while maintaining freshly baked quality, making it possible to sell products by mail order to faraway areas that could not be delivered before.

Consumers are also very happy to be able to eat freshly baked food at home.

Furthermore, being able to store products for a long time reduces inventory risk and makes it easier to develop new sales channels.

There are also success stories of customers who have introduced rapid freezing and actually expanded their sales channels and significantly increased sales.

⑤Reduction of additives and preservatives

In recent years, due to the health boom, more and more consumers are becoming concerned about preservatives and additives.

Until now, preservatives and additives have been essential to the production of bread that maintains its quality for a certain period of time. (No mold, no hardening)

For example, emulsifiers are needed to retain moisture inside bread and keep it soft for a long time. Additives may also be used to prevent mold from growing on bread.

This is an important issue for consumers who value the presence or absence of additives and preservatives.

However, by introducing rapid freezing, the use of preservatives and additives for long-term preservation while maintaining high quality is eliminated, making it possible to acquire new customers.

⑥It becomes possible to separate sales and manufacturing.

Manufacturing bread requires large-scale equipment and equipment.

When selling freshly baked goods on the spot, many bakeries have a store that sells bread and a store that manufactures bread.

Therefore, a certain amount of scale is required. A property of the desired size may not always be available in the desired location.

By introducing rapid freezing, it becomes possible to separate the production and sales locations, making it possible to sell bread even in small stores.

This is especially recommended for bakery chain stores.

Recently, bakeries have been opened on the site of former ATMs, with the production taking place elsewhere.

Being able to choose a location to open a store without considering the size of the land is a big advantage.

A system that takes advantage of these benefits is called a "central kitchen", so if you are interested, please check out this article ↓

What is a central kitchen? Quality doesn't drop! 【merit and demerit】

In addition to the above-mentioned benefits, rapid freezer we handle allow you to put baked bread into rapid freezer ``without cooling it.''

This not only significantly reduces work time and labor, but also enables efficient production and increases production volume.

In addition, by rapid freezing freshly baked bread, it is possible to prevent the moisture from evaporating, which conventionally occurs when cooling bread, making it possible to keep the bread in its best condition. Ta.

View product materials for rapid freezer

Is only baking possible for rapid freezing? What about dough and semi-baked bread?

You have read this far,

“Can bread be rapid freezing only after it is baked?”

Some of you may have this question.

Actually, that's not the case.

When rapid freezing bread, you can select from three patterns: ``dough state'', ``half-baked'', and ``baked''.

If you want to actually bake it at the store, freeze it in the "dough" or "semi-baked" state; if you want to bake it and then just thaw it, freeze the "baked" product.

These options can be selected according to the objectives and strategies of each business operator.

・Bread dough/half-baked: Freshly baked bread can be provided on the spot. In some cases, it may be necessary to use special yeast.

・Baking: The key is that it can be easily frozen and thawed.

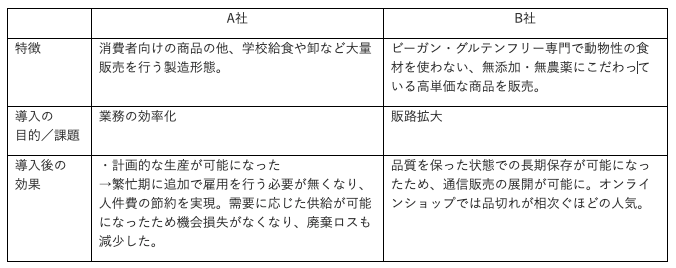

Introduction example of rapid freezing bread

We would like to introduce an example of a bakery business that actually introduced rapid freezer.

These two companies are just examples, but we found that rapid freezing brings great benefits to bread manufacturing and sales.

Conclusion

How was it?

This time, we introduced rapid freezing as a solution for bakeries who are having trouble with bread production and sales.

rapid freezing makes it possible to improve operational efficiency and expand sales channels, leading to great business opportunities.

In fact, there are cases where customers who have installed rapid freezer have expanded their sales channels and increased sales by more than 100 times.

We offer demonstrations of rapid freezing, so you can try out your products.

Why not take this opportunity to consider installing rapid freezer?

![[Storage period increased by 30 times! ] Achieving a stable supply of raw whitebait!](https://shunkashutou.com/wp-content/uploads/2016/11/579c55e6d32e1385c250e8e7c3ed59a71.jpg)

![[Sales increased 100 times! ] rapid freezing the signature menu “Ni-katsu sandwich”!](https://shunkashutou.com/wp-content/uploads/2016/11/IMG_02391.jpg)

![[Horse sashimi] We have significantly reduced waste loss with rapid freezer!](https://shunkashutou.com/wp-content/uploads/2016/11/5fda59d0cbcdabde18e58c3c58c09ed0.jpg)

![[Storage period increased from 3 days to half a year! ] Restaurants are expanding their business using wholesale and mail order!](https://shunkashutou.com/wp-content/uploads/2018/04/66c19942ab4ba346fdb64ccc04cde373.png)

![[Reduce loss from 200 kg of oysters to zero] Improve loss and expand business with rapid freezer](https://shunkashutou.com/wp-content/uploads/2018/06/19785ca583a8d3c4041c7c192d041b0d.jpg)

![[Should be frozen! ? ] How to freeze and thaw bread, 5 carefully selected recipes!](https://shunkashutou.com/wp-content/uploads/2023/10/4691acc32cab80284fa0cddf72d58e95.jpg)

![How to freeze rice balls, storage period, and arranged recipes [use leftover rice]](https://shunkashutou.com/wp-content/uploads/2023/10/2431752695ba1372808f3603c896a5d3.jpg)

![[Be good at saving money! ] Introducing the method and recipe for freezing fried rice](https://shunkashutou.com/wp-content/uploads/2023/10/mayo-tyahan-1024x768-1.jpg)

![[A must-see for restaurants that serve rice] What is rapid freezing that can preserve rice for a long time?](https://shunkashutou.com/wp-content/uploads/2024/05/c62e7b670b6a349aa31ef2d681a21137.webp)

![[Bringing fresh cakes nationwide] How to dramatically increase profits at a pastry shop?](https://shunkashutou.com/wp-content/uploads/2024/09/661ea3ee6264fab6520017622c656870.webp)

![[Improve customer satisfaction] What can be solved by introducing rapid freezer at a lunch box delivery company for the elderly?](https://shunkashutou.com/wp-content/uploads/2024/07/c8a5aa8730d5ae7441fd1aa6ee8757ef.webp)

![[Achieving low cost and high quality] The problems of pubs can be solved with a quick freezer!](https://shunkashutou.com/wp-content/uploads/2024/09/11d55612344a4cbad2ad506ae700c81b.webp)

![Introducing the method and recipe for freezing eringi mushrooms [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/08/a360f0e10b69512c896510215ae51a7f.jpg)

![[Delicious frozen squid recipe! ] Tips on how to eat squid deliciously and without waste](https://shunkashutou.com/wp-content/uploads/2023/10/f3bc339b6bcaff01bd8e2aaa4257acfe.jpg)

![[Current situation and countermeasures for food loss] What are efforts to reduce food waste and rapid freezing? ?](https://shunkashutou.com/wp-content/uploads/2024/04/ddc2c5b7fa32b837dcbdcd1ab68e9087.jpg)

![[Agriculture] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_nogyo_img_01.jpg)

![[Can it be frozen? ] Introducing a good way to freeze green peppers and side dish recipes](https://shunkashutou.com/wp-content/uploads/2023/09/30407f106c5c082468c66af0d40c5858.jpg)

![How to freeze potatoes and a great time-saving recipe! [Moms must see! ]](https://shunkashutou.com/wp-content/uploads/2023/10/potato1-768x512-1.jpg)

![[Increase sales! ] Three reasons why ramen restaurants should install rapid freezer](https://shunkashutou.com/wp-content/uploads/2024/08/deb66347f085932482279d9069d398c8.webp)

![[Many repeat customers! ] Increase sales by mail ordering our proud curry by rapid freezing!](https://shunkashutou.com/wp-content/uploads/2018/08/S__295895302-863x10241.jpg)

![[Includes recommendations by industry] Summary of types and benefits of small rapid freezer](https://shunkashutou.com/wp-content/uploads/2020/12/smallsize.jpg)

![[Required for food business operators] What is the reason for implementing HACCP and using rapid freezing?](https://shunkashutou.com/wp-content/uploads/2017/02/b9dcd4b8ff706013bae4aafeda989b6e.jpg)

![[Import/Export Industry] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_yunyu_img_01.jpg)

![[For food manufacturers] What is the meaning of IQF freezing and what is rapid freezer required for it?](https://shunkashutou.com/wp-content/uploads/2017/03/40008d9f1a752dd006399fe1c4beda34.jpg)

![[Must-see for beginners] What's so great about rapid freezers? Easy-to-understand explanation of the mechanism and benefits!](https://shunkashutou.com/wp-content/uploads/2020/12/9abf7961bd75c2a2af6fb61767b4fdb1-1.webp)

![How to freeze tomatoes, storage period, and 5 recipes! [Explanation with photos! ]](https://shunkashutou.com/wp-content/uploads/2023/10/tomato-768x513-1.jpg)

![Explaining how to freeze tempura with photos! [Storage period, thawing, carefully selected recipes]](https://shunkashutou.com/wp-content/uploads/2023/10/51f33cde78d02d01a9e827132e4f069d.jpg)

![[Supervised by a nutritionist! ] How to freeze bean sprouts, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/34f4d39c30e79629a89bf54221841964.jpg)

![[Explanation with photos] How to freeze nagaimo, storage period, and 5 recipes!](https://shunkashutou.com/wp-content/uploads/2023/09/c46c238f2048d76de403dfd81ddad1f3.jpg)

![[Fisheries/Fisheries Cooperative] Advantages and success stories of introducing rapid freezer](https://shunkashutou.com/wp-content/uploads/2015/05/jirei_suisan_img_01.jpg)

![[Fruit becomes dessert! ] How to freeze kiwi and sweets recipes](https://shunkashutou.com/wp-content/uploads/2023/09/ecc0fc2bc14391ea13ce2e7a43d1416e.jpg)